PolySmooth™ & Polysher™

Ran across this looking for vapor chamber designs that wouldn't kill me and my entire family, set my house on fire, or give us all cancer.

Anyone have any experience with these?

http://www.polymaker.com/shop/polysmoothpolysher/

Ease of PLA printing with alcohol vapor smoothing? Sounds like a unicorn...

Anyone seen the unicorn?

Re: PolySmooth™ & Polysher™

Unicorn review:

To me it seems to do more to make prints shiny than really smooth. If want a shiny look without paint, it does seem to work. And it lets you sand, then smooth, without requiring paint. But if you are going to sand and paint your models, it seems pretty pointless.

As far as risks are concerned; that machine is a potential (though small) thermobaric bomb, creating a highly explosive fuel air mixture. Now Im sure Polymaker did all they could to make it safe, and its probably a lot safer than a DIY solution, but it still is what it is.

Re: PolySmooth™ & Polysher™

To me it seems to do more to make prints shiny than really smooth.

Thanks for the video.

You say it doesn't make it super smooth... what layer heights have you tried it on?

Re: PolySmooth™ & Polysher™

Its not my video, and I dont own one!

Re: PolySmooth™ & Polysher™

Its not my video, and I dont own one!

Ah, okay.

I knew it wasn't your video, but I guess I took your summation of the video to be personal experience with one.

Re: PolySmooth™ & Polysher™

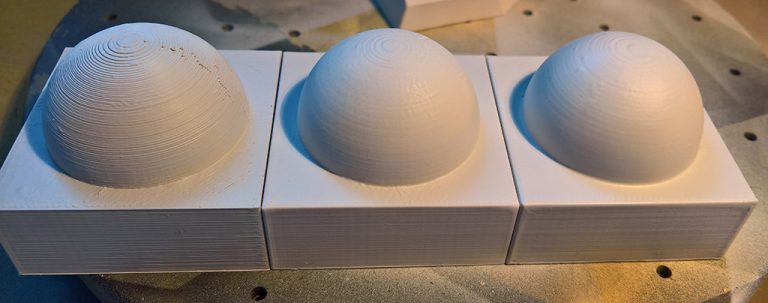

Here's a few tests i did. A simple sphere on a square. Smoothed, then airbrushed with a single thin coat of Vallejo grey PU based primer:

from left: 0,2mm layers, no smoothing at all

middle: 0,2mm layers, 20 minutes smoothing

right: 0,3mm layers, 40 minutes smoothing

It does smooth things, but it's not as smooth as I'd liked it to be...

Re: PolySmooth™ & Polysher™

It does smooth things, but it's not as smooth as I'd liked it to be...

Nice.

Seems like maybe they needed higher proof alcohol or longer in the chamber? Why'd you pull them out when you did (Like, what was your thought process, not like, what the hell is wrong with you? lol)

Re: PolySmooth™ & Polysher™

This was made with 99% Isopropyl alcohol. The manual says: try 20minutes at first. So that's where i got the 20 minutes from. 40 minutes at 0,3 was fully random.

This is just a small sample set from a total of so far 12 prints of this kind. Then I got sidetracked. I am still working on finding the best procedure. Theres a problem with smoothing too long, it eats away sharp edges and thin walls. You can already see how the front right corner in the 2 smoothed samples in my picture ended up being rounded out and almost look swollen. This is not a bad paintjob, its how it came out of the Polysher.

Smooth too long, and things get gooey. And something else I ran into, too long and horizontal surfaces where the alcohol is pooling get a very interesting looking, almost leathery, scarred texture... Cool effect if you want that, but not if you're looking for smooth.

I switched to transparent Polysmooth then and did some interesting tests in vase mode. You can smooth it to a point where it basically turns flexible, like plastic stretch foil. Very interesting things going on there.

I think the maximum time you can smooth something is therefore limited. It was also very interesting to see how different surfaces (like horizontal, or vertical walls, edges, etc) react to the smoothing process. I think to make best use out of the Polysher requires a good amount of trial error to get the hang of. One thing that impressed me, but I wasn't able to reproduce myself yet is the goldfish tank example Polymaker has on their website..

If that sort of experimenting is something that strikes your fancy, you should get one. It is fascinating. And it does save labour for postprocessing. I was surprised how well the 0,3mm Layer print turned out.

Re: PolySmooth™ & Polysher™

This was made with 99% Isopropyl alcohol. The manual says: try 20minutes at first. So that's where i got the 20 minutes from. 40 minutes at 0,3 was fully random.

That could potentially be an issue because I think 70-90% is the recommended range for the alcohol. Even beyond the obvious potential difference of using a weaker solvent, the filament is hygroscopic so God only knows what additional chemistry and physics occur when you're basically saturating the plastic with water.

I could imagine that, if nothing else, the pools, swelling, and rounding off of edges might be reduced. Just a thought. "Low and slow" seems to be the best way of doing... everything?

If that sort of experimenting is something that strikes your fancy, you should get one. It is fascinating. And it does save labour for postprocessing. I was surprised how well the 0,3mm Layer print turned out.

Yeah.

I'm completely a newbie to 3D printing (I'm 5 or 6 weeks away at this point from even having my own printer), but my current finishing technique is dry sand, wet sand, 3x coats of automotive filler/sander, wet sand, 2-3 coats of spray paint... And I got really great results with that, in terms of surface finish.

From everything I've read and seen, I'm thinking if I sand the model down enough to get rid of all of the major surface imperfections (specifically, strings, wonky overhangs, support nubs, etc), the polysher could take the place of the filler sander / wet sanding steps to give me a smooth surface that's also suitable to remain unpainted (Once you sand, you've got an ugly POS...)

I'll talk myself into buying one eventually. I appreciate hearing about your experience with it.