Filament Seizes in Hotend

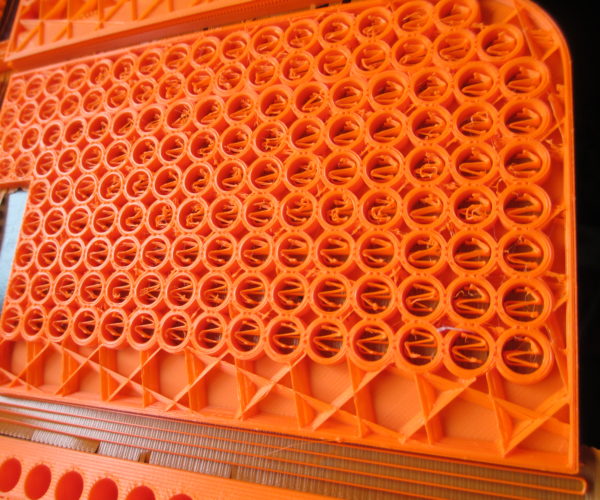

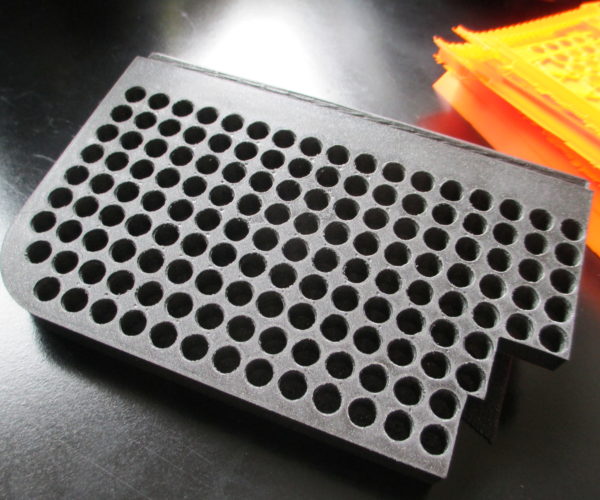

My extruder will print fine for the first few layers, but then the layers become thin and broken before the filament stops coming out. The hotend will stay hot and the extruder motor turns correctly, but the filament is visibly not moving through. I checked all of my electrical connectors and adjusted the bearing tension, but the problem persists. I have been having this problem since I changed my PLA spool from "Galaxy Black" to "Orange". See the included photos of the bit holder I have been trying to print. The bit holder has two halves that will be joined together when completed. The galaxy black spool printed the first object fine, but the orange spool seems to be having trouble with the other half. My theory is that because of the complexity of each layer, the extruder is retracting too quickly and too frequently, causing the gear to chew into the filament and preventing further movement. Any ideas? Has anyone had this problem?

Best Answer by --:

If when unloading the filament you see a stub that is 2.2 mm in diameter you might be suffering a heat break jam. Prusa uses a modified version of the E3D-V6 heat break. The mod is a change in bore from 2.0 mm to 2.2 mm. This bore change leaves a step in the heat break neck, just above the melt zone. With parts requiring hundreds of retractions, the filament melt can migrate upwards where it cools and becomes a 2.2 mm slug that can no longer fit into the lower 2.0 mm section of the heat break.

The only known fix is to replace the heat break with a stock E3D-V6 version that does not have the step.

I have a pet theory - unproven - that printing abrasive material or printing for thousands of hours may increase the chance of this behavior (the heat break bore is polished, and abrasives or use roughens the 2.0 mm bore).

Also - some filaments behave differently than others: the fluid characteristics especially. One plastic brand may jam while another doesn't.

RE: Filament Seizes in Hotend

If when unloading the filament you see a stub that is 2.2 mm in diameter you might be suffering a heat break jam. Prusa uses a modified version of the E3D-V6 heat break. The mod is a change in bore from 2.0 mm to 2.2 mm. This bore change leaves a step in the heat break neck, just above the melt zone. With parts requiring hundreds of retractions, the filament melt can migrate upwards where it cools and becomes a 2.2 mm slug that can no longer fit into the lower 2.0 mm section of the heat break.

The only known fix is to replace the heat break with a stock E3D-V6 version that does not have the step.

I have a pet theory - unproven - that printing abrasive material or printing for thousands of hours may increase the chance of this behavior (the heat break bore is polished, and abrasives or use roughens the 2.0 mm bore).

Also - some filaments behave differently than others: the fluid characteristics especially. One plastic brand may jam while another doesn't.

RE: Filament Seizes in Hotend

@tim-m30

That makes a lot of sense. As I mentioned, I used a different filament for the other half with no problems. So to clarify about the "heat break", you say there is an uneven seam where the melt zone meets the upper portion feed tube, and the melted filament can get caught on that edge and form an enlarged "plug"?

Thank you for taking the time to read and answer my question.