Baffling problems under the microscope

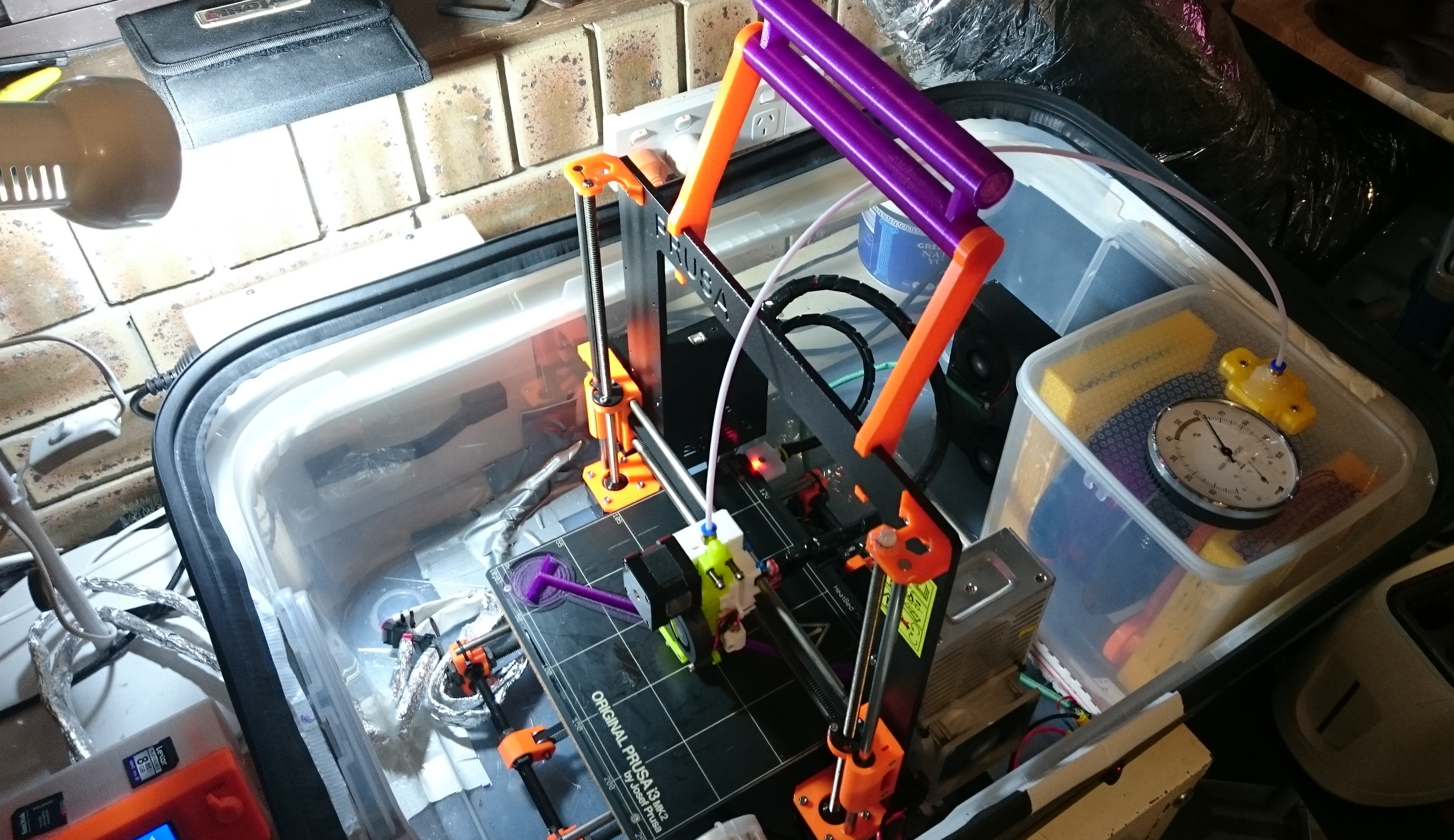

I decided to dust off the microscope to try to figure out why my PRUSA i3MK2 is a useless waster of filament recently.

Several earlier threads have revolved around a similar, maybe identical, issue. But I cannot find a thread that ends in "Eureka, this is why and here is how to fix it!".

I am printing surfboard fins. With much effort, I have developed ways how to do it, using PLA rather than PC or other stronger materials, and then adding the mechanical strengths by inserting carbon rods.

But for the last 2 months or so, my PRUSA i3 MK2 it throwing random problem layers at me, so much that I cannot print a fin, except for the odd random exception due to sheer dumb luck.

The weak layers occur with different filaments, and they occur at different locations when using the same .gcode file again for a re-print. As far as I can tell, they occur at random.

Re: Baffling problems under the microscope

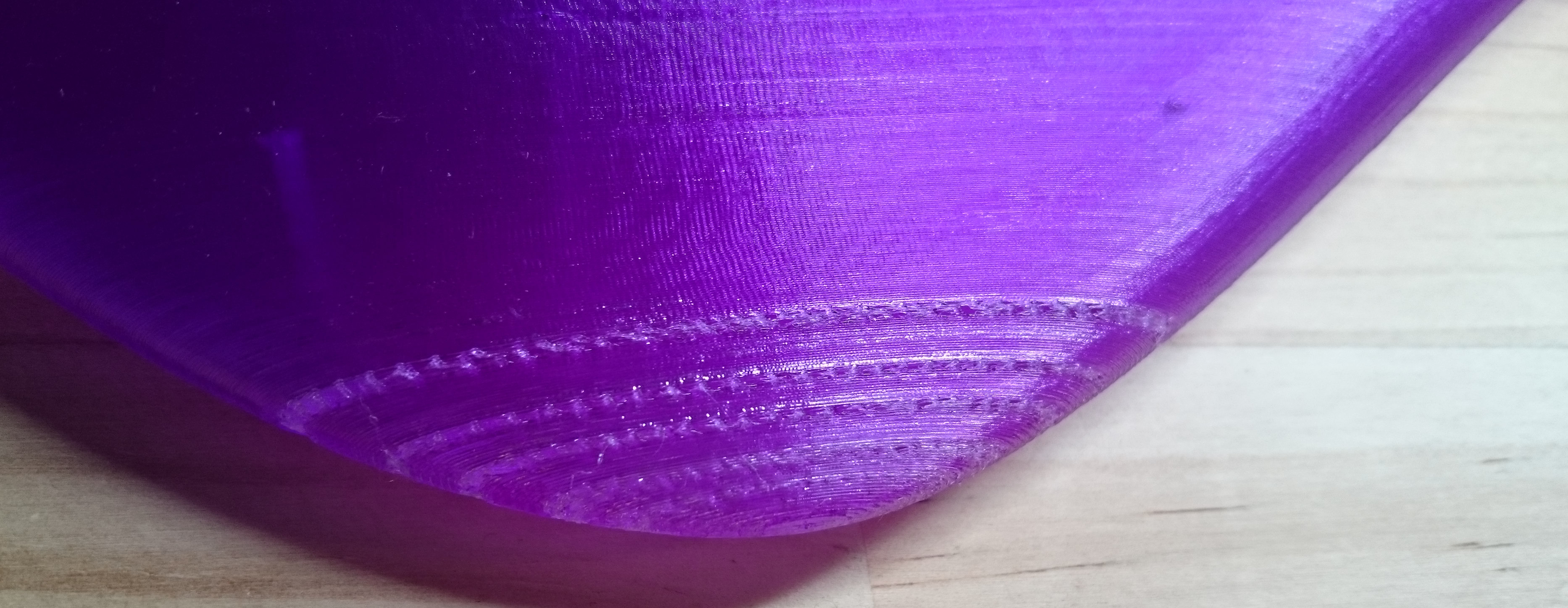

The layers that are weak allow the fin to be snapped off along those lines quite easily.

It looks like blobs of molten filament are deposited, rather than a continuous line. These blobs are then covered by the next, normal layer of filament. The normal layer is basically being printed 0.2mm above the last normal layer, falls down onto the last normal layer, and curves over the blobs in the abnormal layer.

Tome, it looks like the filament is not being pushed, but oozes out slowly while the extruder keeps moving.

I'm not 100% certain, but it seems that it's always a complete layer that is affected. I never see a layer where this happens half-way along.

Re: Baffling problems under the microscope

MrMik

Would you like to upload the problematic STL file which I can then slice and print to see if I get the same issues?

We may then be able to resolve your problems.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Baffling problems under the microscope

Sure, I don't mind, I just don't expect that you will have any problem printing the file. The weak lines occur randomly, at different locations when the same .gcode is printed again.

How would you like me to share the file? At what stage in the process? Export STL from OpenScad?

If the problem was caused by the slicing software (I use Slic3r), could it occur at different z-heights in consecutive prints from the same /gcode file?

Re: Baffling problems under the microscope

When I tired to post the contents of the STL file, I go this error message:

Your message contains 6929555 characters.

The maximum number of allowed characters is 60000.

So it's 2 orders of magnitude too large for this site.

Re: Baffling problems under the microscope

Yeah, you need to zip the file and then drop the zip onto a post.

There is a very small chance that the problem could be the slicer, but my best guess would be some intermittent hardware issue.

Do you power cycle before a print? Any problem will spool holder? direct feed from spool to extruder? The MM printers have an advantage win spool and feed over the single filament version.

Drive pulley clean? When did you last change the PTFE and nozzle? Is PTFE chamfered at lower end and seated tightly against the heat break?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Baffling problems under the microscope

I realised I should not share that exact file, because it is an attempt to improve someone elses work, and they are trying to sell them.

I think it's OK to make a screwless snap-in version of that fin for myself, but sharing the file is not OK.

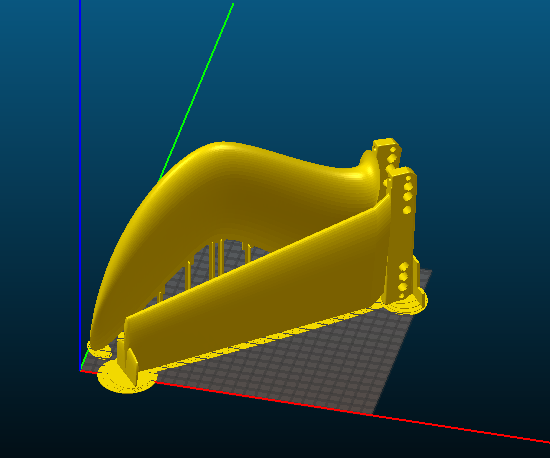

So, instead, I include the zipped STL file for a fin that I concocted myself, based on the McCoy Gullwing fin.

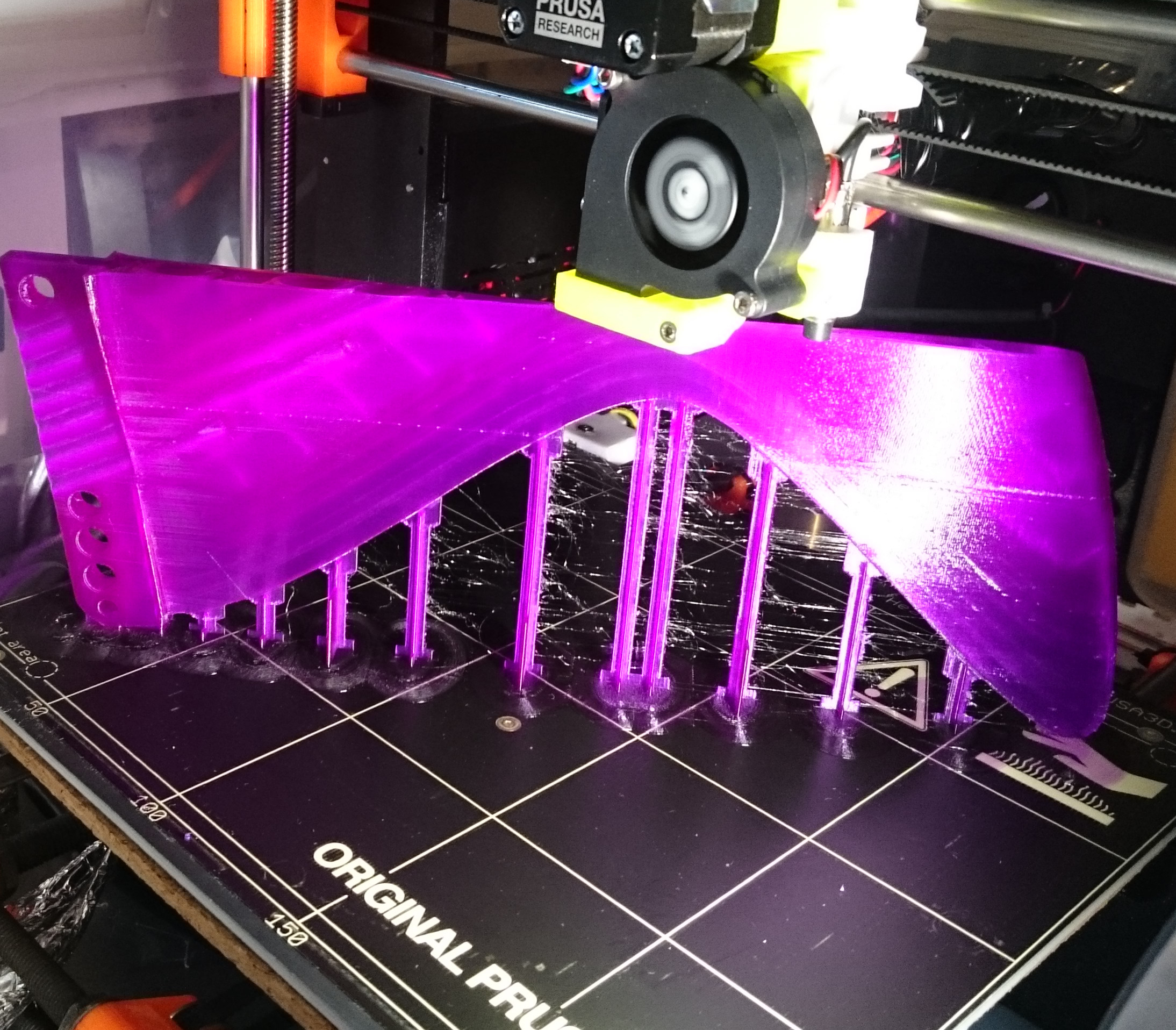

In the first picture you can see that this fin file is also affected by the weak-blob-line error when printed as a fin with infill.

Just a single weak-blob-line in this one:

The next photo shows the nose of the same fin, this time printed as a hollow shell, to be filled with carbon rods and epoxy resin.

I put it under the microscope and the 'nose-rings' are the same lines of blobs instead of continuous filament that cause the weak lines in the prints with infill.

But there are 3-4 consecutive blob-layers before a number of normal layers occurs again.

I have seen that many times, particularly with fins that have bumpy leading edges, when the print speed is very slow at the end of the print. In these hollow shell fins, the weak layers always occur towards the tip of the fin, towards the end of the print.

Ooops, seems 3 attachments is the limit, I'll attach the zip file in the next post.

Re: Baffling problems under the microscope

The attached zip file is the STL for the curved fin in the Slic3r screenshot. The other fin is the one that I dont want to share.

I have spent several hours today sorting failed and good prints and stacking them up in chronological order, and labeling them, comparing them to my notes, trying to figure out what is happening.

I found one weak-blob-line starting (or ending) in the middle of a layer, there are probably others. This rules out one hypothesis, that the failure to extrude is dependent on the particular z-level and starts and ends exactly with that layer. Because I print with around 5 perimeters for the fins with infill, it is quite likely that the faulty blob-line starts and ends in one of the inner layers 80% of the time.

What I had not mentioned before is that occasionally, a print fails with a notch ground into the filament. I managed to temporarily improve (reduce) the occurrence of weak-blob-lines in the fin tips by straightening the teflon tube between filament box and extruder to reduce friction. I also tried to go back to using the filament holder as in the standard setup, but it did not help. The plastic box is filled with desiccant and keeps the filament dry until it gets to the hotend. I have been using it since long before this problem started. However, the problem seems to get worse at the end of a roll of filament, when it is more tightly coiled and then causes increased friction inside the teflon tube.

In summary, it looks to me like the hobbed pulley fails to grip the filament properly at times. Or the stepper motor does not turn the hobbed pulley. Then the PLA oozes out and deposits blobs instead of a continuous line of filament.

Why it mostly starts to work again before a notch has been ground out of the filament is a mystery.

For now I'm trying to print the same finicky fin file with 0.35mm layer height. That more than doubles the feeding rate for the filament, and if slow speed is really making it worse, than maybe it will print OK.

Re: Baffling problems under the microscope

Yeah, you need to zip the file and then drop the zip onto a post.

There is a very small chance that the problem could be the slicer, but my best guess would be some intermittent hardware issue.

Do you power cycle before a print? Any problem will spool holder? direct feed from spool to extruder? The MM printers have an advantage win spool and feed over the single filament version.

Drive pulley clean? When did you last change the PTFE and nozzle? Is PTFE chamfered at lower end and seated tightly against the heat break?

Peter

I also think intermittent hardware failure is the cause. Maybe even the filament. I did examine it closely and there is a bit of fluctuating thickness, between 1.68mm and 1.74mm. One piece of filament with a notch ground out of it appears particularly thin distally to the notch (I mean the part that has not gone past the hobbed pulley yet). When measured with the wider part of the digital caliper, I measure 1.69 to 1.70mm; with the sharp part at the tip of the caliper it might be as low as 1.67mm, but that depends a lot on how hard I push.

Could differing grades of softness, rather than thickness of the material cause it?

I do turn the printer off almost every time between prints.

Spool holder and PTFE tube seem in good nick. Whenever I found the notch in the filament and extrusion had stopped completely, I carefully examined the system for any hang-ups that stop the filament from feeding, but could not find any. The filament always reloads without a hitch. I have done numerous cold pulls which produced clean extruder casts, but did not fix the issue.

The drive pulley looks dusty when a notch has been ground, but appears to clean itself with normal use. I have also cleaned it manually but it did not help. I replaced the hobbed pulley during upgrade to the improved cable management system and installation of a new heated bed on 29-4-2017. I also installed new heat-sink fan, nozzle fan, PINDA probe and 40W heater. I re-used the hotend temp sensor with new cables soldered on.

I did not use a new stepper motor or solder new cables to the old one. Cable breakage is high on the list of potential problems, because almost every one of my prints uses the full X- and Y- range of the printer, causing maximum bending of the cables.

I'm not sure when I replaced the PTFE tube in the heat sink, or if it is chamfered. I think I must have installed it properly, because I got 2 flawless fin prints after the partial rebuild. I thought I finally have a printer that just works, but then the weak-blob-layer problem started with the third print after the rebuild.

I have not updated to the latest firmware, not sure what is running in there now, but it was there before the problem commenced.

Re: Baffling problems under the microscope

Doing some Taulman Bridge Nylon cold pulls.

Heating nozzle to 230C, then let coold down while pushing manually, until below 50C (no pushing needed below 180C).

The set nozzle temp to 230C and pull on filament while nozzle heats up. Somewhere between 140C and 180C it pulls out.

Does the shape of the nozzle casts around the heatbreak/hotend junction allow to judge if the PTFE tube is in properly?

Re: Baffling problems under the microscope

Apologies; I have been away over the weekend.

OK, looking at your cold-pulls. Two things there

The black bits being withdrawn; it's not a lot, but I had a roll of white PLA which was doing the same. Every couple of prints the extrusion became very "iffy" and cold-pulls removed some black bits. Then it was OK for a print or two.

The upper cold-pull looks to have produced a "mouse condom" of sorts which does indicate that the interface between PTFE and heat break is not as it should be.

You may find that both chamfering and tapering the bottom end of the PTFE will help. Basically do the same as is required for the MM upgrade. There's a picture here: http://shop.prusa3d.com/forum/original-prusa-i3-mk2-multimaterial-f26/blockage-troubleshooting--t4643.html#p34017

I am on catch=up at the moment; will try to get the time to download/print your model later.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Baffling problems under the microscope

Apologies; I have been away over the weekend.

OK, looking at your cold-pulls. Two things there

The black bits being withdrawn; it's not a lot, but I had a roll of white PLA which was doing the same. Every couple of prints the extrusion became very "iffy" and cold-pulls removed some black bits. Then it was OK for a print or two.

The upper cold-pull looks to have produced a "mouse condom" of sorts which does indicate that the interface between PTFE and heat break is not as it should be.

You may find that both chamfering and tapering the bottom end of the PTFE will help. Basically do the same as is required for the MM upgrade. There's a picture here: http://shop.prusa3d.com/forum/original-prusa-i3-mk2-multimaterial-f26/blockage-troubleshooting--t4643.html#p34017

I am on catch=up at the moment; will try to get the time to download/print your model later.

Peter

Thank you Peter, much appreciated.

While test surfing one of the fins today, or rather while driving to and from the beach, I came to the conclusion that I need to try the beveling and chamfering of the PTFE tube. Someone linked you diagram in another thread. I'm quite certain that I did not do anything much after cutting the new PTFE tube to size. I think I poked a spike into it to make sure the lumen is clear and maybe a bit flared, but that's it.

That would be so nice if just adjusting the PTFE tube fixes this messy problem!

The print at 0.35mm layer height produced a number of other problems, but no weak-blob-layers at all. My hypothesis that this problem occurs more likely at very low extrusion speeds might be right.

Unfortunately, the hollow cylinders are blocked by sagging loops of filament. I guess thicker extrusion takes longer to cool and therefore bridges don't set before they sag badly.

And there are many areas where the vertical surface of the model is rough, although I used "External perimeters first".

Well, looks like i have to take the hot-end apart again.

Re: Baffling problems under the microscope

I have not experienced personally experienced this, but I have read that improperly stored PLA can absorb moisture and that the absorbed moisture can be released as steam as the filament passes through the hot end--causing bubbles and weak layers in the affected prints.

Is it possible that your filament has excess moisture in it?

Re: Baffling problems under the microscope

I have not experienced personally experienced this, but I have read that improperly stored PLA can absorb moisture and that the absorbed moisture can be released as steam as the filament passes through the hot end--causing bubbles and weak layers in the affected prints.

Is it possible that your filament has excess moisture in it?

Good thought, but I keep it surrounded by desiccant all the time. Just a habit formed when I tried to print using nylon.

Also, moisture would likely be distributed evenly through the filament and not just affect clustered layers. There would be little defects everywhere, not near-total failure concentrated in a few areas with the rest in perfect condition.

Re: Baffling problems under the microscope

In order to get another data point, have you considered using a different slicer to see if the bad layer is related to the mk2 vs. the gcode generated?

Re: Baffling problems under the microscope

In order to get another data point, have you considered using a different slicer to see if the bad layer is related to the mk2 vs. the gcode generated?

I have only ever used Slic3r Prusa version.

I don't think it could be due to the slicing, because the identical .gcode file sometimes prints well, sometimes poorly, and the weak-blob layers appear at varying locations, at least semi-randomly.

I took the hot-end apart but have not put it back together yet.

Does anyone know a link to a good comprehensive instruction on how to put the PTFE tube In? Exact length etc?

Re: Baffling problems under the microscope

looking at the black bits in the pull, could they be bits of burnt filament caused by a rough inside of the nozzle. this leads to a partial blockage, which clears the next time it retracts

they are made down to a budget, looking at the inside of some recent ones i got, it looked like someone had got a chisel and cut it out with that. the rough surface will trap parts of filament and cause them to overheat and caramelise (burn), these form blobs and can partially block the nozzle.

what i do is to polish the inside of the nozzle using a cocktail stick (toothpick) and some brasso, the cocktail stick is soft enough to poke through the rnd of the nozzle thereby polishing the exit.

i have had problems like this but they seem to have reduced with this technique.

i think i have written it up on my site, might be worth taking a look

just a thought mind

if it used to work and doesn't now then check what you have got

try replacing the nozzle for a new one - polish it first

or try coolong the electronics if you are not already - the extruder drive maybe overheating. and recovering by skipping steps.

good luck in solving it

phil

helping others with 3d printer problems

building 3d printers

showing you can repair almost anything with a 3d printer and innovation - well, design!!

www.best3dprinter.stan-tech.com

Re: Baffling problems under the microscope

looking at the black bits in the pull, could they be bits of burnt filament caused by a rough inside of the nozzle. this leads to a partial blockage, which clears the next time it retracts

they are made down to a budget, looking at the inside of some recent ones i got, it looked like someone had got a chisel and cut it out with that. the rough surface will trap parts of filament and cause them to overheat and caramelise (burn), these form blobs and can partially block the nozzle.

what i do is to polish the inside of the nozzle using a cocktail stick (toothpick) and some brasso, the cocktail stick is soft enough to poke through the rnd of the nozzle thereby polishing the exit.

i have had problems like this but they seem to have reduced with this technique.

i think i have written it up on my site, might be worth taking a look

just a thought mind

if it used to work and doesn't now then check what you have got

try replacing the nozzle for a new one - polish it first

or try coolong the electronics if you are not already - the extruder drive maybe overheating. and recovering by skipping steps.

good luck in solving it

phil

Thanks Phil, much appreciated.

I am pondering if the extruder is getting too weak for some reason. Here is why:

- when I use 'Load filament' at 190C to 210C for a filament specified for a 190-230C nozzle temp, then I hear clicking noises during the phase of the 'Load filament' that extrudes the thick extrusion. Pushing the filament down manually into the extruder at that time does not help at all.

- only when I increase the nozzle temp to 220-230C does this dis-aappear. I think it is getting worse, i.e. the minimum temperature at which I can 'Load filament' without clicking and missing steps is increasing.

I'm wondering if I should increase the supply voltage to 12.5V or 12.7V to boost the power of the stepper motor.

Question: Will setting 'High power' vs 'Silent' change the power of the extruder motor during 'Load filament'? ( I only use the one button on the Pruse I3MK2, no USB cable or external software).

Re: Baffling problems under the microscope

Question: Will setting 'High power' vs 'Silent' change the power of the extruder motor during 'Load filament'?

It does increase motor current slightly, but that is unlikely to be the issue.

It may be if you have a brass pulley that the teeth are becoming slightly worn.

Increasing the tension will possibly cause filament damage and prevent good feed.

Increasing PSU voltage will have little or no effect as the motors are current limited.

Peter

P.S. sorry, I still haven't had chance to print your model. Very busy atm.

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Baffling problems under the microscope

you have the ability to see small - why not set it up to see what is happening with the extruder gear.

this way you will see whether it is just cutting into the filament or another problem

if it is cutting in then the blockage is further down the line

try removing the brass nozzle and pushing filament through - cold

if you have a gap between the nozzle and the ptfe then filament can build up here and cause a blockage.

after removing the nozzle try to see if anything is preventing filament coming out.

if you say manual pushing will not feed it then it is totally blocked above the point where the filament goes into 'plastic' phase.

this forms the plunger to force the filament out of the nozzle and if it becomes too long can freeze at the top causing a jam.

remove heater block and see what is in te ptfe tube

good luck

helping others with 3d printer problems

building 3d printers

showing you can repair almost anything with a 3d printer and innovation - well, design!!

www.best3dprinter.stan-tech.com