Spool Holder Issues

I received my MM kit and made the upgrade last weekend, so far everything is working properly except for the spool holders. When I first loaded the spool holders with PLA they worked fine, until halfway through a print when the PTFE Trap Clips (new version) popped out of the spool holders. This continued to happen until I taped them down with masking tape as a temporary fix. This prevented the PFTE Trap Clips (new version) from popping out, but it created a new issue when I switched to my PETG filament.

I've been using Hatchbox PETG filament and it seems like it's knotted up on the spool. These "knots" are causing the extruders to pull the filament holders all the way to the printer bed where they begin bumping into my prints. I've tried several things to keep the spool holder from sliding/moving, but nothing is working.

TL;DR Spool Holder keeps moving and the PTFE Trap Clips (new version) keep pulling out of their slot.

Has anyone else experienced these issues? Does anyone have any advice or design improvements?

Thanks!

Stephen

P.S. My next step is altering the SH-Bearing-Corners files so they have a tab to mount the holders to a piece of wood. Thoughts?

Re: Spool Holder Issues

Doesn't matter how good or bad the spool holders are if the filament is knotted on the spool.

You need to re-wind those spools.

And yes, I have had issues with the spool holders and ended up printing my own with larger bearings in the centre of the spool.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Holder Issues

Peter,

Do you care to share photos of your spool holders? I'm curious to see how you designed your holders. Thanks!

Doesn't matter how good or bad the spool holders are if the filament is knotted on the spool.

You need to re-wind those spools.

And yes, I have had issues with the spool holders and ended up printing my own with larger bearings in the centre of the spool.

Peter

Re: Spool Holder Issues

Here you are...

The other "trick" I use is to cut the PTFE feeder tube in half so that when unloading the filament does not go all the way back to the spool - only to the cut in the tube.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Holder Issues

Hi Peter,

do you use a full length of PtFE from the spool holder to the extruder?

My Spool holders came with about 100mm PTFE each, and I didn't see any indication that we should use additional PTFE...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Spool Holder Issues

Hi Peter,

do you use a full length of PtFE from the spool holder to the extruder?

My Spool holders came with about 100mm PTFE each, and I didn't see any indication that we should use additional PTFE...

regards Joan

That's interesting. I have about 60cm od PTFE tubing for feeding filament from spool holder into the rear of the extruder motor, where there is a recess for the PTFE tubing.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Holder Issues

Hi Peter,

do you use a full length of PtFE from the spool holder to the extruder?

My Spool holders came with about 100mm PTFE each, and I didn't see any indication that we should use additional PTFE...

regards Joan

That's interesting. I have about 60cm od PTFE tubing for feeding filament from spool holder into the rear of the extruder motor, where there is a recess for the PTFE tubing.

Peter

Peter,

Thanks for sharing your setup. My setup came with 100mm of PTFE just like Joan mentioned above. I've been thinking about buying some PTFE so I could route the filament as well.

The extruder parts that I received only have an opening for PTFE tubing on the hotend side of the extruder. I might try to make an adapter so I can attach some PFTE since this should fix the spool holder movement issue.

Thanks, Stephen

Re: Spool Holder Issues

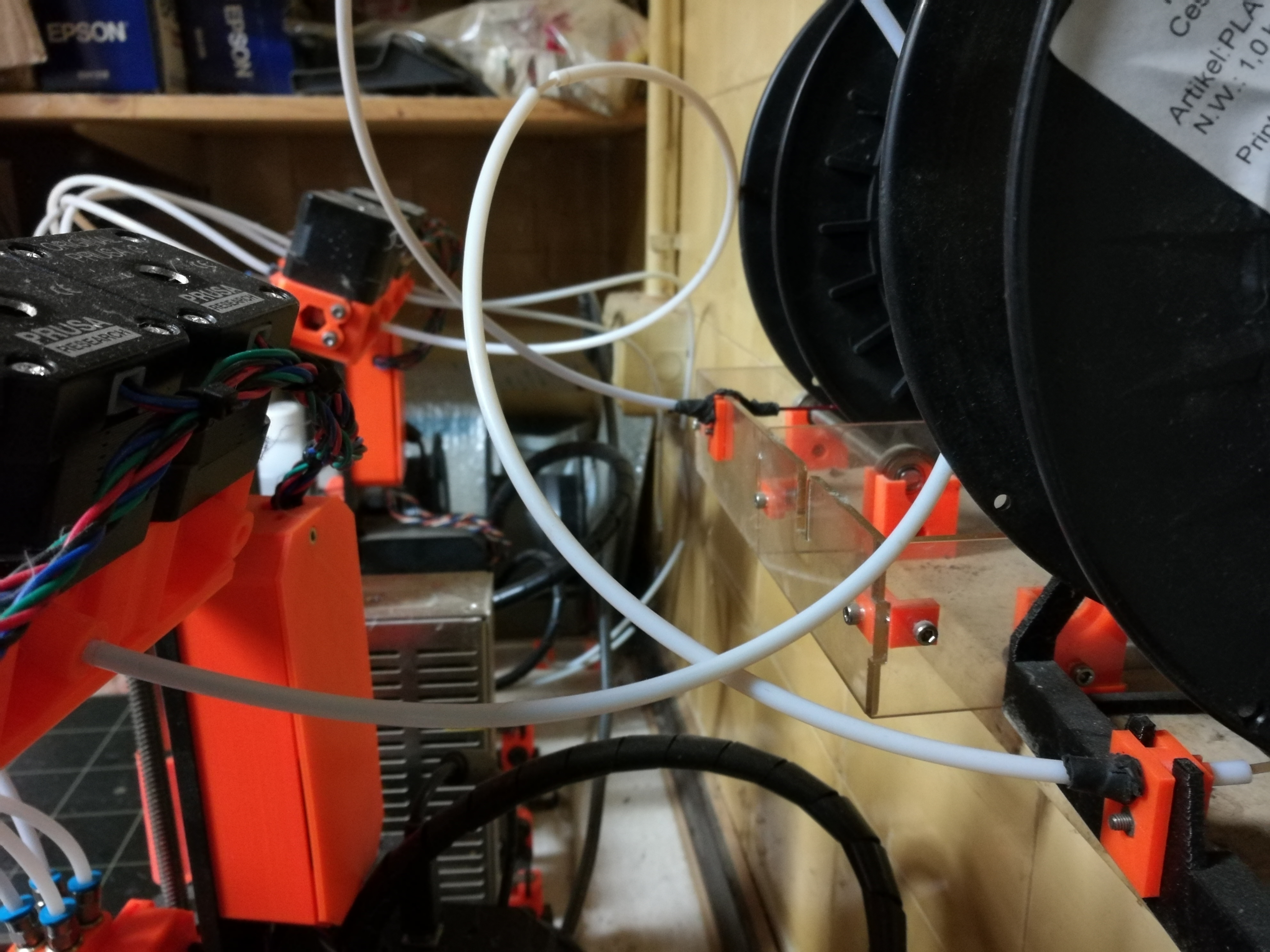

OK, here's a picture from behind showing the PTFE tubing:

A couple of things to note:

I have used self-amalgamating tape to hole the tubes in place.

There are 2 printers; the closest filament spool goes to the second printer, further away and you can see where the PTFE tube is cut.

The furthest filament spool (in the original spool holder) enters the rear of the closest extruder - you can't see the cut in that tube ; it's above the frame.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Holder Issues

I currently have my MMU sprawling across a table from when I built it, but I would really like to get it back into it's home. Which means I need a method to load/change filament from the front of the machine.

My MMU also came with just the short FTPE tubes for the spool holder, but I have bought a bunch more so that I can "route" the opening to where I have better access. My initial thought was to try to put a Festo on the extruder body and thus have FTPE tube coming out of it, and I could push the filament in till it hits the hob gear for loading, all from the front. (I am pleased that the loading of the extruder is much more direct than before - less "feel" required.

But I see from Peter's photos that you can just push in the tubing right into the extruder. Maybe tack it in place with a little silicone glue (easily removes).

But I am not understanding the cuts that Peter talks about. (I see them in the photo, but don't understand why.)

In my set up, I want my spools above the printer, so I was going to have a tube run from the extruder through the base to the top area. It should be a gentle arc so no binding, I then have a multi-material spool holder of my design to load into them.

My question is do people see a problem with this, and what are the purposes of Peter's cuts?

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Spool Holder Issues

Hi Aaron.

Firstly, on one printer, I have the spool holders on a window sill immediately behind the printer. In that instance I don't use PTFE from spool to motor at all - as long as the path is pretty straight, there is no need.

The extruder body has 4mm recesses where the PTFE tubing is held in place, but this is not a requirement and unless the tubes are cut, it is possible to have problems on unloads.

Let me explain...

The filament spools from PR are nice large spools and 1KS takes up about three quarters of the spool. Other manufacturers use smaller spools and really do have to fill them up to get the 1KG of filament on them.

With new "full" spools, unloading almost 100mm of filament can push the filament back onto the spool and because of the natural twist in the filament, it can go past the side of the spool (at the top) and quickly get tangled and not be able to feed.

I came up with the solution for not having the the PTFE attached to the extruder motor housing, bu printing some small parts with a 2.4mm centre hole and a 4mm recess for the PTFE preventing the PTFE from being retained in the housing on unload and also preventing the filament feeding back to the spool.

However, with the festo issues I experienced (and Bowden tubes getting shorter as a result), I cut new bowden tubes from the feeder tubes which meant that the feeder tubes had 2 sections (the cut in the middle). The unloads only unloaded to the cut in the feeder tube, so I no longer had to stop those tubes being retained within the motor housings.

The other effect of this is less drag during loads and unloads.

I do hope this explanation helps...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Holder Issues

Peter,

Thank you so much for the time and explanation. It helped a lot.

Right now, I do have a straight path - and have no tubes at all. But for my intended set up, I want a controlled path from the printer to a top layer where I can access it. (Basically a full 180 degree arc.) I had not really thought about the (rather violent) unloading dynamics. I will consider that as I make plans and experiment. This helped a lot.

I will post success and failure for others, when I get around to it. (Likely next weekend.)

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Spool Holder Issues

I'm not sure I understand the desire to have PTFE from the spool to the extruder intake. During retractions and unload-during-color-change, I would want the "loose" filament to not be pushed back onto the spool, which often leads to filament unwrapping off the edge of the spool, especially with fuller spools (and PETG).

As much as I appreciate the 4-spool Prusa design, it takes up a lot (a lot) of space, and I don't have the required space behind my printer nor do I have a convenient shelf I can set it on. I never print with the extremely wide Prusa filament spools - most of mine are "standard" or narrower and all that space taken up by the Prusa spool holder(s) is wasted, at best, and very limiting as far as placement goes.

So, as a lot of people are doing, I'm designing my own. It will be made from v-slot extrusion and printed holders. The spools will sit on their rims on the 608 bearings instead of on a shaft (as in Prusa's) or on a center shaft. I plan on the spools sitting slightly behind and just above the row of extruders and feeding the filament down from the back of the rack, through short PTFE tubes for filament control, as Prusa is doing.

Here's what the printed spool holders look like:

I've been using a similar spool holders for several years on different printers, including my pre-MM MK2, and it's very nice to just set a spool on it and not have to feed it onto a central shaft. The new ones, in the picture, have a bar that rides in the v-slot (glued on, with pegs to ensure alignment.) They're very stable. Since I'm printing the M8x25 bolts and nuts and all the corner blocks and bracing and re-using the Prusa bearings, I only need to buy the extrusions and a few M5x10 screws and T-nuts. And since I already have those parts (leftovers from D-Bot build), it's just costing me some filament and some time. I still need to design the v-slot tubing holders for the back rail, and cut the extrusions, but it's coming together quickly - should be done today, if I can get off my butt and cut those extrusions.

Re: Spool Holder Issues

I'm not sure I understand the desire to have PTFE from the spool to the extruder intake.

Quite simply, it allows the spools to be positioned wherever you want them.

I also find that the small bearings on the edge of the spool are not ideal, hence my spool centre larger bearings which run a whole lot smoother than the ones supplied. In fact, I used the supplied bearings for fidget spinners..

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Holder Issues

I also find the Prusa-design (spool edge on shaft) to not spin very well. (BTW, the carbon-fiber tubes are no more - the newer upgrade kits have aluminum tubes.)

However, I have to say that with the design I'm using (spool edge directly on the bearing), the spools spin very freely. Maybe a little too freely, so the short PTFE tube will help with that.

And while I intend to have my in-use spools in one general spot and don't need the tubes to manage that, I can easily see another advantage of using the tube from spool to extruder as you are doing - you don't have a half-meter of loose filament dangling around behind the printer. I may use that on my design, if that situation turns out to be problem for me. Thanks.

Re: Spool Holder Issues

BTW, the carbon-fiber tubes are no more - the newer upgrade kits have aluminum tubes.

Ha... I have steel rods which are ground down to fit the bearings. But that was what was used during the testing.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Holder Issues

Peter,

I am curious, it looks like you have a different extruder holder than the "standard issue" MM upgrade kit. From your picture (in your 5-Jul post) it looks like the filament is fed much more horizontally than in the standard model. My MK2S feeds filament at ~60 deg upward angle, which causes the filament (before entering the extruder) to collide with the hotend cable bundle. Your picture looks like the filament enters the extruder almost flat.

Did you make your own extruder holder, or where did you get this from?

Best,

Knut

Re: Spool Holder Issues

Peter,

I am curious, it looks like you have a different extruder holder than the "standard issue" MM upgrade kit. From your picture (in your 5-Jul post) it looks like the filament is fed much more horizontally than in the standard model. My MK2S feeds filament at ~60 deg upward angle, which causes the filament (before entering the extruder) to collide with the hotend cable bundle. Your picture looks like the filament enters the extruder almost flat.

Did you make your own extruder holder, or where did you get this from?

Best,

Knut

Peter was part of the beta testing team. Those mounts were one of the last iterations before the production version was finalized. The stl files are not available anywhere.

Re: Spool Holder Issues

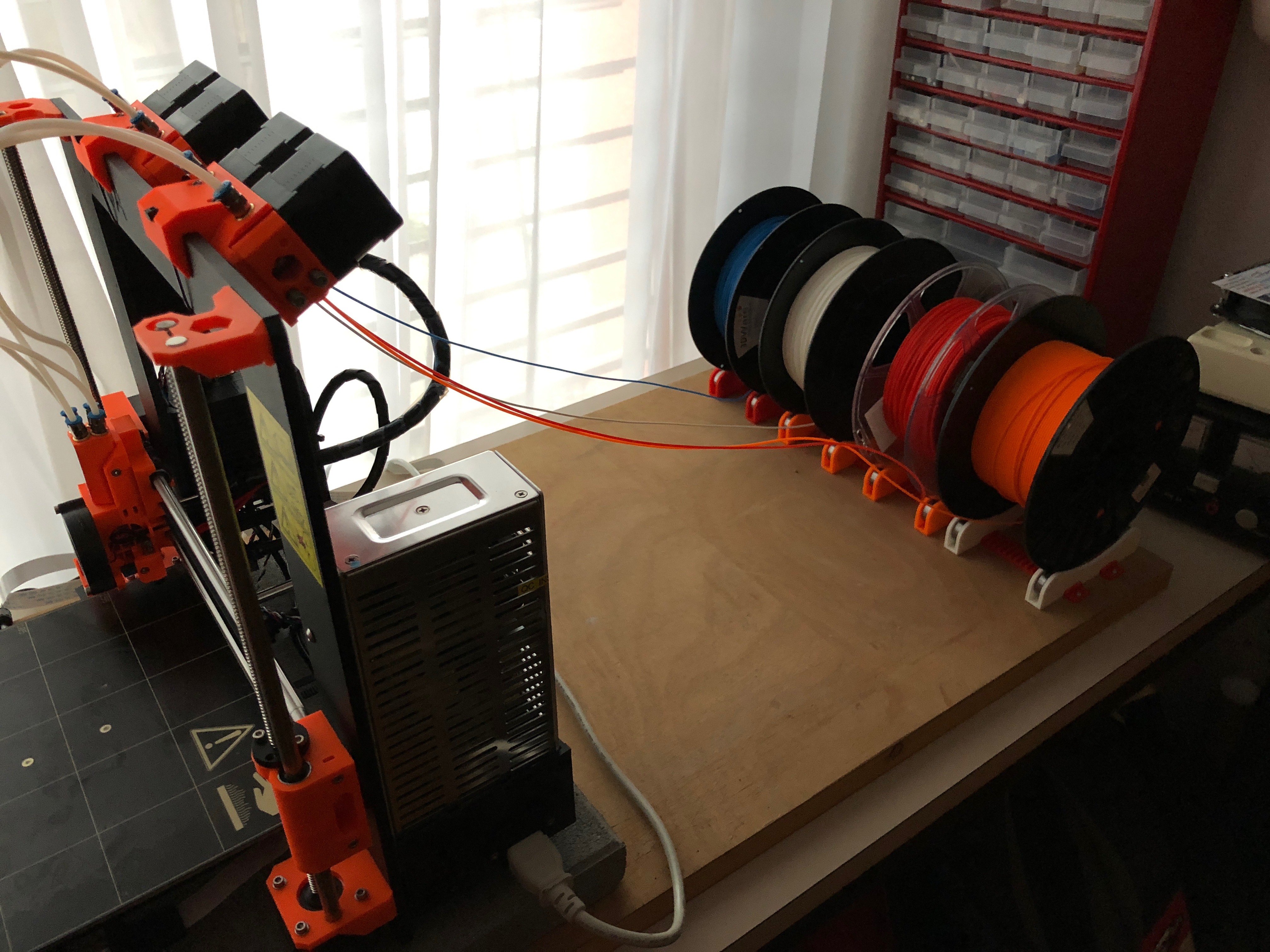

I'm printing with good success using this setup:

I even didn't use the new shorter PTFE tube guides as they are used in the PRUSA spool holders. Interestingly I don't have any issue with back spooling when not using them. The gap between the holders can be changed for wider filament spools.

The design is taken from Thingiverse : https://www.thingiverse.com/thing:2451368

I modified the rails at the bottom: added screw holes and wider gap since the above design was too tight to easy mount the bars.

Here is the re-designed stabiliser: https://www.thingiverse.com/thing:2766899

Re: Spool Holder Issues

Would you say the concrete slab helps with vibrations? I'm asking because I considered getting one, but subjectively >95% of my vibration issues were gone after the MMU upgrade (I guess partly due to the lighter printhead but mainly due to less weight on top of the frame). Coming from cube-style printers actually having this problem came as quite a shock.

That said, your solution looks neat but I would try to feed the filament from a higher vantage point and move the holder closer. The constant snapping noises when it tangles & untangles (sometimes with the wire harness) used to drive me mad.

Re: Spool Holder Issues

I'm using the slab since I've bought the printer. First without the MMU and now I've kept it underneath. Still I think it is a benefit, if not for the noise then for sure for additional mechanical stability of the printer itself since my work bench isn't rock solid.

To avoid the snapping and it's annoying noise I've wrapped PTFE self sticky tape around the harness. Now the filament slides well on top of it.

I want to increase the filament location - good point - by using a new solid frame - which is currently under construction 😉

Here the tape I've used: https://www.chukoh.com/products/tape/tape/asf-110_fr.html

And here my harness: The filament slips like on oil on it 🙂