More MMU experiences

I thought I would just share some of the things I've come across in trying to get the MMU to work.

I started off with lots of trouble and could rarely get prints to complete, or it would drop several layers along the way. Once or twice I ran into the blob below the PTFE, but mostly I would get jams in the steel tubes. I quit printing with it for a while and then ultimately had a run of successful prints. I tried Seth's multiplexer modification just to see how it worked and was 0/2 for good prints (1 was clearly a filament kink issue, the other looked like just a stringing/jamming issue). In switching back to the original multiplexer, I compared the original hotend PTFE I was using and the extra one that came with the kit. The one I had been using was visually different, and had clearly expanded over time (assuming it was correct to begin with).

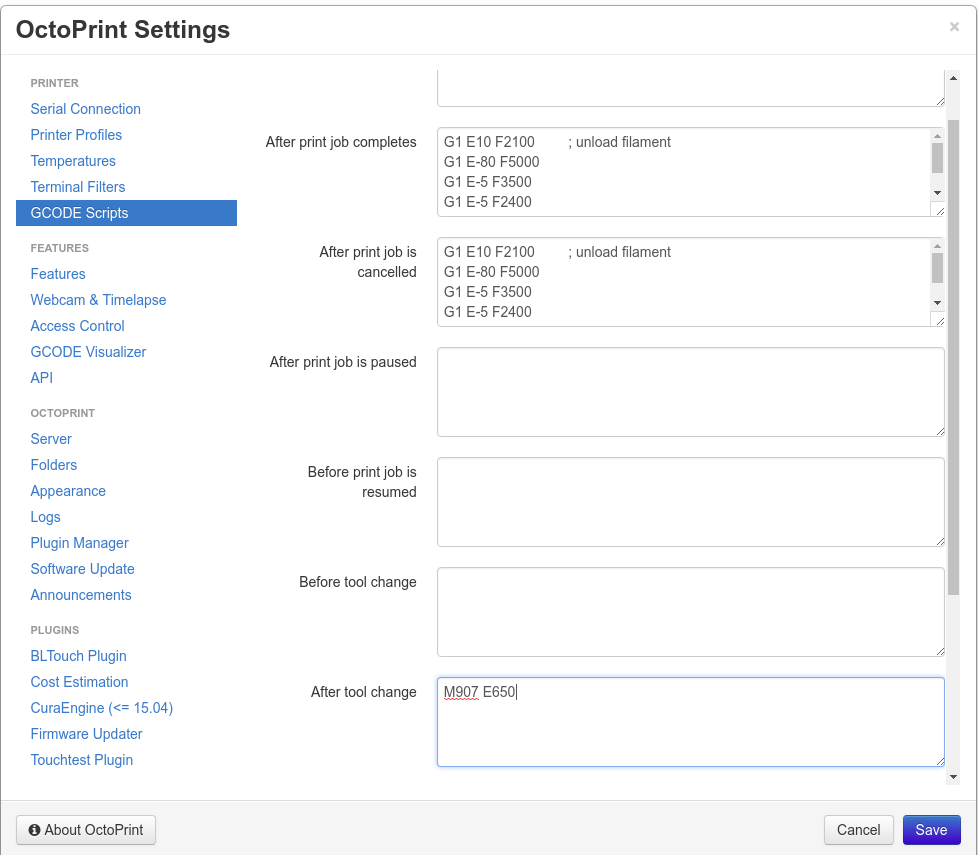

I put in the new PTFE and had about 20 consecutive failed prints in a row. Primes were all good, but usually it was Extruder 3 that would cause issues. Tried multiple filaments, etc. and still failed. Based on how much skipping of the extruder I was hearing, the Extruder 3 path had to have some issues. I cleared everything out and checked again, still skipping extruder. On a lark I decided to just increase the extruder 3 motor current. Boom. Prints started working correctly. I went to 650 (Slic3r defaults to 550) and have since added this to my octoprint post-layer change gcode.

Anyway this has "solved" some issues for me and thought it might be helpful for others.

Re: More MMU experiences

I had a similar problem with a particular extruder jamming. I found that when I moved the steel tube in the multiplexer (or whatever they call it) to a different extruder, THAT one started failing. I ordered a replacement steel tube, and my printer hasn't failed yet. I've done a number of large prints, all successful!

Re: More MMU experiences

Thanks for the very useful info. I had the same problem , more on this below.

Questions?

1- Where exactly did you change the extruder current?

Would putting M907 E650 at the startup g-code do it.

According to this post, the ext. current is 550 default, during tool change it is 750

https://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/increase-extruder-motor-current-t4268.html#p31558

2- Where is the slic3r-pe default current set?

I did not see any M907 in the gcodes generated by slic3r-pe.

I can print very well and reliably with my MMU.

Initially I had the same problem.

The MMU seems to be quite sensitive to the filament

due to the tight tolerances on the filament path.

I was trying to print Protopasta matte HTPLA, it is continuously building a blob and

wearing the bottom of the ptfe tube, as I painfully discovered.

Eventually it causes persistent failures for all the other filaments.

Changing the ptfe tube solved the problem for me.

I still can't print this HTPLA filament with MMU.

I think the PTFE tubing can be replaced with something else that will avoid such wear.

Re: More MMU experiences

Thanks for the very useful info. I had the same problem , more on this below.

Questions?

1- Where exactly did you change the extruder current?

Would putting M907 E650 at the startup g-code do it.

According to this post, the ext. current is 550 default, during tool change it is 750

https://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/increase-extruder-motor-current-t4268.html#p31558

2- Where is the slic3r-pe default current set?

I did not see any M907 in the gcodes generated by slic3r-pe.

I used octoprint to make the adjustments. It places an M907 E650 after tool changes, which effectively bumps the current up during normal operation.

They are there in my gcode: M907 E750 for load/unload and M907 E550 for normal operation

Re: More MMU experiences

I used octoprint to make the adjustments. It places an M907 E650 after tool changes, which effectively bumps the current up during normal operation.

They are there in my gcode: M907 E750 for load/unload and M907 E550 for normal operation

Ahhemm 😀 How did you do this in Octoprint?

Thanks for your reply!

John