Re: Blockage troubleshooting.

Just about prints with a single filament, the intermittamt grindng is painful to listen to but now I'm faced with a few hours of cleanup up to do. Sadly I think I'm throwing the towel in on the MMU.

It's just not worth the hours of work I have put in to it to be presented with this.

Re: Blockage troubleshooting.

OK, let's simplify things a bit.

Slice a model and print. Upload the photo (with the stringing) and also zip up and upload the G-code and STL.

I will print your G-code and then slice the model for you to print.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

OK, let's simplify things a bit.

Slice a model and print. Upload the photo (with the stringing) and also zip up and upload the G-code and STL.

I will print your G-code and then slice the model for you to print.

Peter

Peter,

I've now set my extrution multiplier to 1.0 it was 0.98 and I have added the M900 K200 back in to my start gcode. Grinding has almost gone but I am printing the Prusa Logo at the moment, not the multipart in the previous picture.. Tomorrow morning I will get my Octoprint RPi out connect it to the printer and start the stringy print off again. Then I will be able to monitor it remotely just to make sure it's printing ok.. I will post the results back here.

I have attached the multipart gcode file... pre M900 K200 & 1.0 extrution multplier adjustments.

Re: Blockage troubleshooting.

I have attached the multipart gcode file... pre M900 K200 & 1.0 extrution multplier adjustments.

Thanks. Will have a look and try printing.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Since this seems to be the general "blockage" thread, here is my first one.

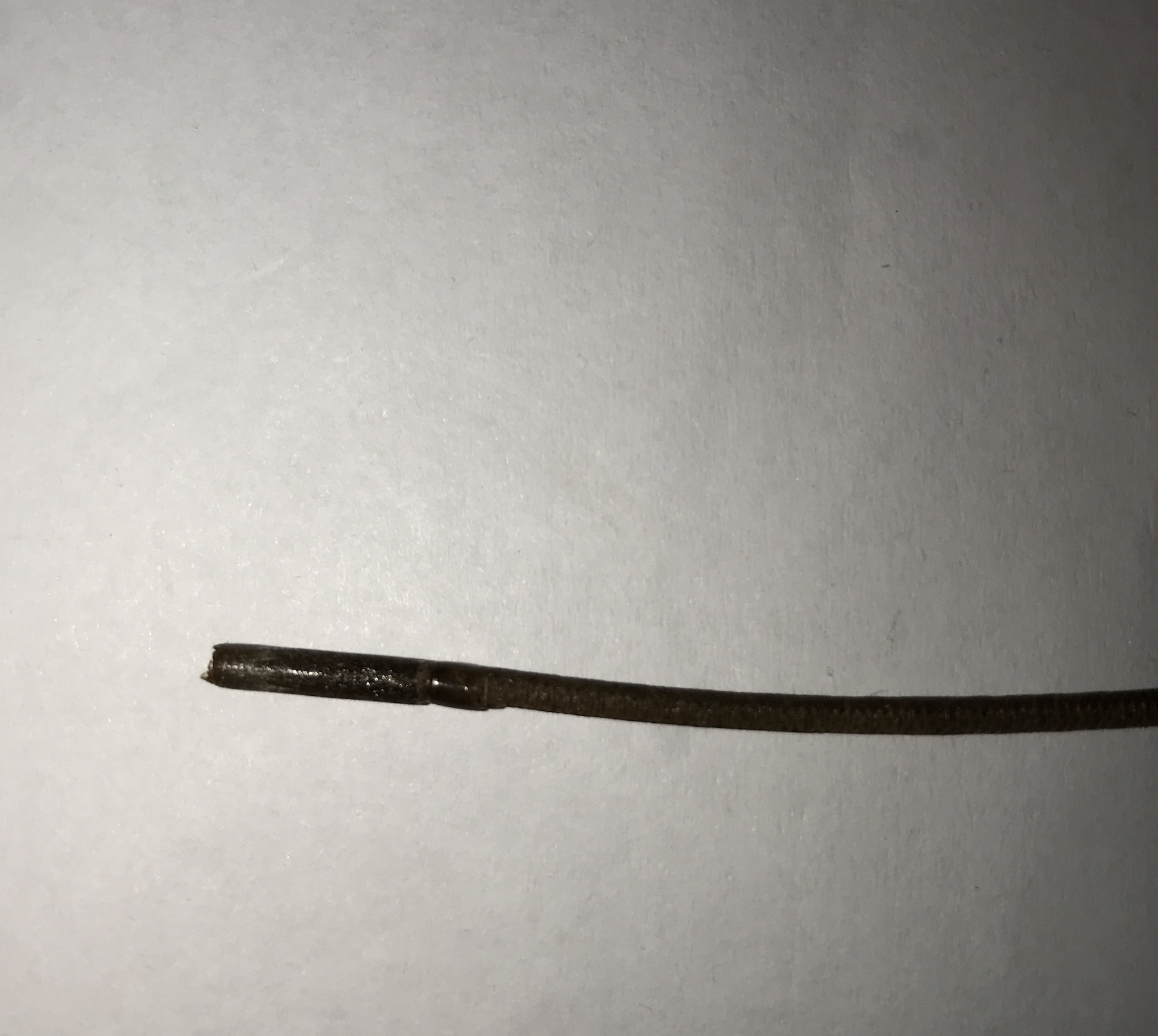

Printing some wood PLA. First printing at 215Celcius, but that was clearly too high because the filament wasn't oozing but pouring out of the nozzle. Needless to say tons of stringing. So I tried a second run at 205 Celcius and there after 5mm in height (printing a 20mm test cube) I had a blockage. After removing the necessary parts this is what I pulled out of the extruder:

The bottom, wider, part was stuck below the PTFE tube in the hotend.

So my questions:

- is this because of the lower temperature?

- why doesn't it even melt when being pushed in the hot end?

- how can I avoid this? I clearly need a lower temp for printing than the 215 I used. On the spool it says: 190 - 215 degrees so 205 is still within range.

Re: Blockage troubleshooting.

Maybe someone can elaborate on the topic of bore diameters...obviously somewhere below the PTFE it must be wider, otherwise we wouldn't get these wider blobs.

Where exactly is the differing bore diameter located (inside the heatbreak and if yes where, between heatbreak and PTFE or between nozzle and heatbreak)? Is it a sharp change or a bit tapered? Why choose a different diameter at all?

All I can say is I had original 1.75mm E3D Bowden hotends in other printers and I've never seen this, so I would assume those more or less match the PTFE inner diameter.

Re: Blockage troubleshooting.

Maybe someone can elaborate on the topic of bore diameters...obviously somewhere below the PTFE it must be wider, otherwise we wouldn't get these wider blobs.

Where exactly is the differing bore diameter located (inside the heatbreak and if yes where, between heatbreak and PTFE or between nozzle and heatbreak)? Is it a sharp change or a bit tapered? Why choose a different diameter at all?

All I can say is I had original 1.75mm E3D Bowden hotends in other printers and I've never seen this, so I would assume those more or less match the PTFE inner diameter.

Nils, it's all in this thread.

Basically the nozzle is 2mm ID, then chamfers into the lower part of the heat break which is 2mm ID. The upper part of the heat break is 2.1mm up to the PTFE tubing which is chamfered from 1.85mm ID.

The melted filament should not get into the 2.1mm part of the heat break.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Tomorrow morning I will get my Octoprint RPi out connect it to the printer and start the stringy print off again. Then I will be able to monitor it remotely just to make sure it's printing ok.. I will post the results back here.

Print completed... Same, same but different.

The Z-Height is also still on the move, it's getting smaller but its definatley shrinking.

Re: Blockage troubleshooting.

Print completed... Same, same but different.

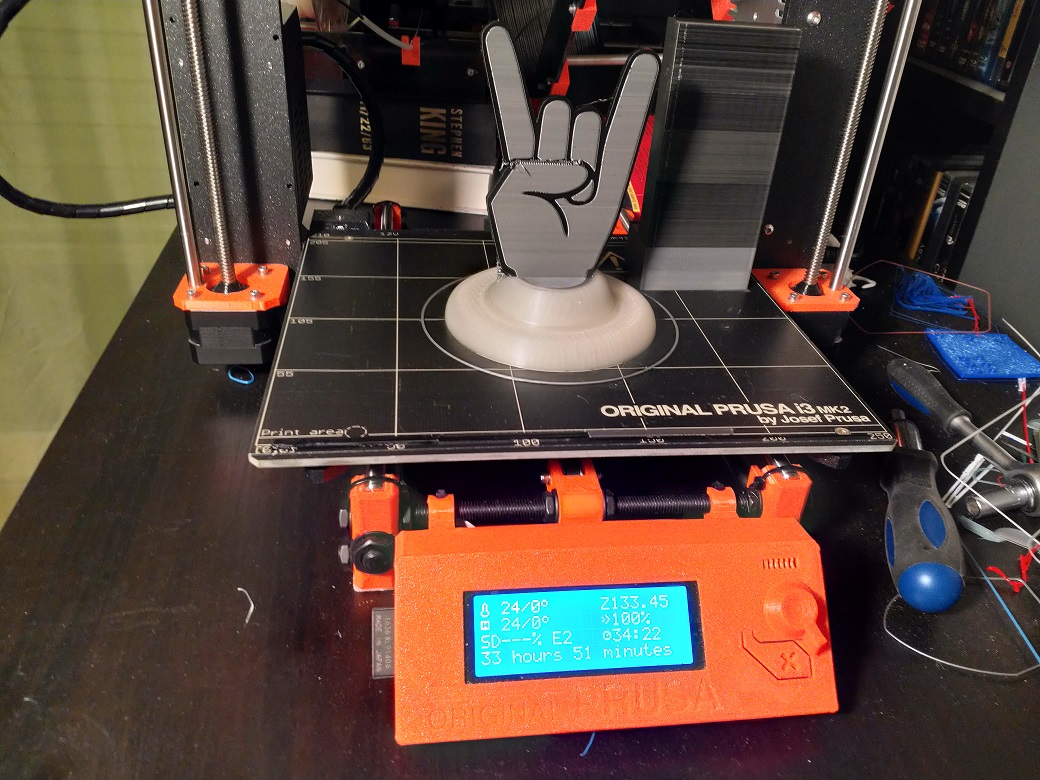

Just finished (apologies for the delay.

I made the following changes to the G-code you uploaded:

Changed to E2 (simply because I had white filament in E2

Added my PID settings

Added my G80 bed levelling code

I used while PLA from my local supplier and power cycled the printer before starting the print. Printed via OctoPrint.

I have no idea where to go with this next. You may want to try a different filament.

Unfortunately there has been no input from PR on these issues and I find myself in a difficult situation, so I have decided to retire myself from these forums.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Peter,

This print looks great.

Your example and help make us (at least me) improve our printers and our proccess to print.

We know you are not Prusa, you are only the wise guy who help us with the problems caused by a product for people who loves to spend time fixing machines.

Please be around here... 😉

Re: Blockage troubleshooting.

Peter,

Please be around here... 😉

Problem located. Heat break is leaking. I have attempted a minor fix for now and I have a print running which looks 100% better than everything I have printed before.

Peter, thank you for your time in helping and being around here. I have been reading your post for a while, a long while and only as a last ditch attempt to resolve my problems I posted here. I know I am not alone and there are many many others who for what ever reason (pride, embarrassment etc. ) who don’t ask for help me included.

So please don’t give up.

Re: Blockage troubleshooting.

Malcinator, now it gets interesting. I'm in pre-christmas-customers-all-over-the-place mode right now and don't know when I have time to look at this, but any chance you have photos? By leaking, do you mean thermal leak or actual filament in the heatbreak thread or between heatbreak&PTFE?

Was it not properly tightened or poorly machined?

PJR, I'm extremely thankful for your attempts. I truly hope PR have not pissed you off too much, and nobody expects you to write so many forum posts. I suggest you take a break and kick back a bit. Every bit of information you can provide has been extremely helpful. I really wish PR would post a summary of their results from support & customer feedback to provide an official systematic approach to find errors (including a point when you're supposed to invoke support). I personally am still unsure whether a new heatbreak would actually help, but at least I can print single again on all 4 extruders in fairly good quality now. Not sure what did it, updated to final firmware from last weak (which made my live Z jump again from -150 to -250), gave the heatbreak a good clean, reset all festos for the 100th time, dialed in all springs and redid PID cal. And suddenly it worked again in single mode. A bit afraid to go back to MM.

Cheers, Nils

Re: Blockage troubleshooting.

TLDR;

My heat break was bent, as far as I can remember it was caused by the nozzle crashing in to the bed. I am continually fighting to find my z-height and that was I suspect was the cause. I didn't try to bend it back I bought a replacement which I installed. I can at this point only surmise that as it didn't come with any thermal paste I either hadn't screwed it together tightly enough or it's just leaking anyway. I will have time tomorrow to take it all apart again and apply some thermal paste to it now I have bought some.

I tried yesterday to print a mult-part model that I have created in tinkercad. I sliced it using the Prusacontrol and tried to print it. Pre heated the printer making sure the PINDA was 50mm away from the bed and loaded all four filaments. Filaments I have used before in single colour mode. The results were a complete disaster first off my z-height was very obviously way to high, not that much in the way of filament was extruded at that point. The purge line wasn't laid down apart from what was left from the last filament. All I had after was grinding then the printer beeped and stopped. The heaters were all on but it was motionless. I tried again, re-slice, unload, reload and same result.

Re: Blockage troubleshooting.

That indeed sounds like a blockage inside the heatbreak. Can you try the following: Remove MUX (but leave short PTFE tube in), heat to PLA temp, cut a section of PLA and mark with a felt-tip pen. Measure the distance between felt-tip mark and upper end of PTFE. Then stick the filament into the hotend directly to see if it blocks. If you need a bit of force (do not push hard!), but can get it to extrude, the blockage is not too far up in the heatbreak. If it does not move at all, heat to ABS temp and repeat until you just barely cleared the blockage. After that measure the new position of felt-tip mark. Now you can calculate the position where it blocks up. It should be constant if you repeat the same print.

When removing the filament make sure you are at PLA temp again, and pull it out quick. Otherwise you'll pull more molten filament into the cold part of the heatbreak and block it up again.

I have had several E3D hotends where I never bothered with thermal paste and never had any issues (also with a Bowden setup and associated long retracts). It could be more critical here, but I wouldn't put my hopes in it. It's more important that it gets properly fastened (see E3D website or PJRs description here).

Re: Blockage troubleshooting.

So, today...

Yesterday the printer wasn't going to print anything at all, nothing. Today I came home and turned it on and printed my multi-colour file with no issues at all. So far I have printed it many times and have swaped the four filament around in print order and still it continues to print. No one sound of grinding from the extruders at all. I haven't touched it apart from turning it on. I can even print using Octoprint, couldn't do that yesterday.

I'm at a complete loss.

I have used the thermal compound to assembel the heat break & heat block and tomorrow I will swap out the one I have installed at the moment. I hope then that will rid me of the fine hair like stringing I'm getting at present.

Re: Blockage troubleshooting.

Having read this entire thread, I was about to lose hope.

I was however able to print successfully today. I have reduced the retraction length to 2.5mm, set the retraction speed to 25 mm/s and the deretraction speed to 50 mm/s. I still get some stringing, but that's better than a blocked hotend and an extruder that's skipping steps.

What I think has been the most important change though, is that I set the temperature for the PLA I'm using (Das Filament white PLA) to 230 °C instead of 210 °C. I found that out by experimenting inside the "Tune" menu while a print was failing. I increased the temperature and the PLA started to flow again. I'll need to tweak everything a bit more, but I've just had a successful print that took a bit over 4 hours.

Maybe the thermistor wires have gotten a bit damaged from taking the hotend out so many times, maybe the connector on the board is a bit wonky, I don't know. What I do know is that I've found settings that work for me.

Thank you all for taking the time to discuss everyone's issues in here, and a special thanks to Peter for doing what PR failed to do: Taking care of people after they gave you money.

Re: Blockage troubleshooting.

This is my first post on this subject, and it is long. I have read all 26 pages in this thread because I have had the same problems with clogging in the MMU that others have had. First I can say without fear of contradiction that the MMU was “not ready for prime time” when it was released! It is not easy to make this work. I have learned a lot from the posts on this thread, especially from PJR. Thanks for all your patience and information.

I have had blockages in the heat break, the PTFE, below the cooling tubes and even at the entry to the extruders. I have disassembled the multiplexer so many times I am afraid I might have worn out the screw holes. I have also cleaned the extruders multiple times due to the slippage of the pulleys. I have found that as Peter has said multiple times it is important to have the PTFE tube exactly tight against the heat break his way. I was finally able to successfully make a four-color PLA print which lasted over 24 hours.

My latest problems came while trying to print objects using Verbatim BVOH as soluble support both total and as interface. Somewhere within the first hour or two the BVOH would block extrusion and ruin the print. When I disassembled the multiplexer I always found the BVOH was stuck between the top of the PTFE tube and the metal cooling tubes with a blob which wouldn’t allow it to go either way. Thinking it was a temperature problem, I printed Peter’s TempTest with PLA and BVOH and found that both printed well between 175 and 215, probably best about 180. But when I tried a print with both at 180, the problem recurred.

This made me suspect that the problem was that the PTFE tubing was not reforming the soft filament during retraction to a diameter thin enough to pass into the cooling tube. I learned this was the way it should work from this forum that the PTFE had to be 1.8-1.9mm inside diameter. I also learned it was so special that Prusa had to order it only from Festo to get the precision needed. So I ordered 2 more MMU PTFE tubes from shop.Prusa (that was all they had in stock). While waiting for the PTFE to arrive I found a way to accurately measure the inside diameter of the PTFE I had been using, including the original tube which came installed in the MMU. I found that the various tubing I had been using measured between 2.10 and 2.20 mm. When the new PTFE arrived, it measured out to be 1.85mm — the diameter it was supposed to be. Needless to say, I was pretty disappointed with the original MMU I received!! I will also be asking Prusa to make this right for me. Since then I have successfully made an eight hour print using the BVOH as full support. When I unloaded the filament it came out easily (not stuck as before) and had clean ends slightly wider than the 1.75mm filament — able to return through the cooling tubes.

Anyone still having blockage between the top of the PTFE and the cooling tubes should check the diameter of their PTFE. The method I used was to mix clear fast set epoxy and force it about 3-5mm into the PTFE tube at the heartbreak (bottom) end and place a piece of twisted wire 3-5mm into the epoxy in the tubing leaving a tail hanging out. Epoxy will not stick to teflon, but it is tight. After the epoxy has thoroughly set, pull it out of the tubing with the tail. Measure the diameter of the epoxy plug with digital calipers.

Re: Blockage troubleshooting.

Anyone still having blockage between the top of the PTFE and the cooling tubes should check the diameter of their PTFE.

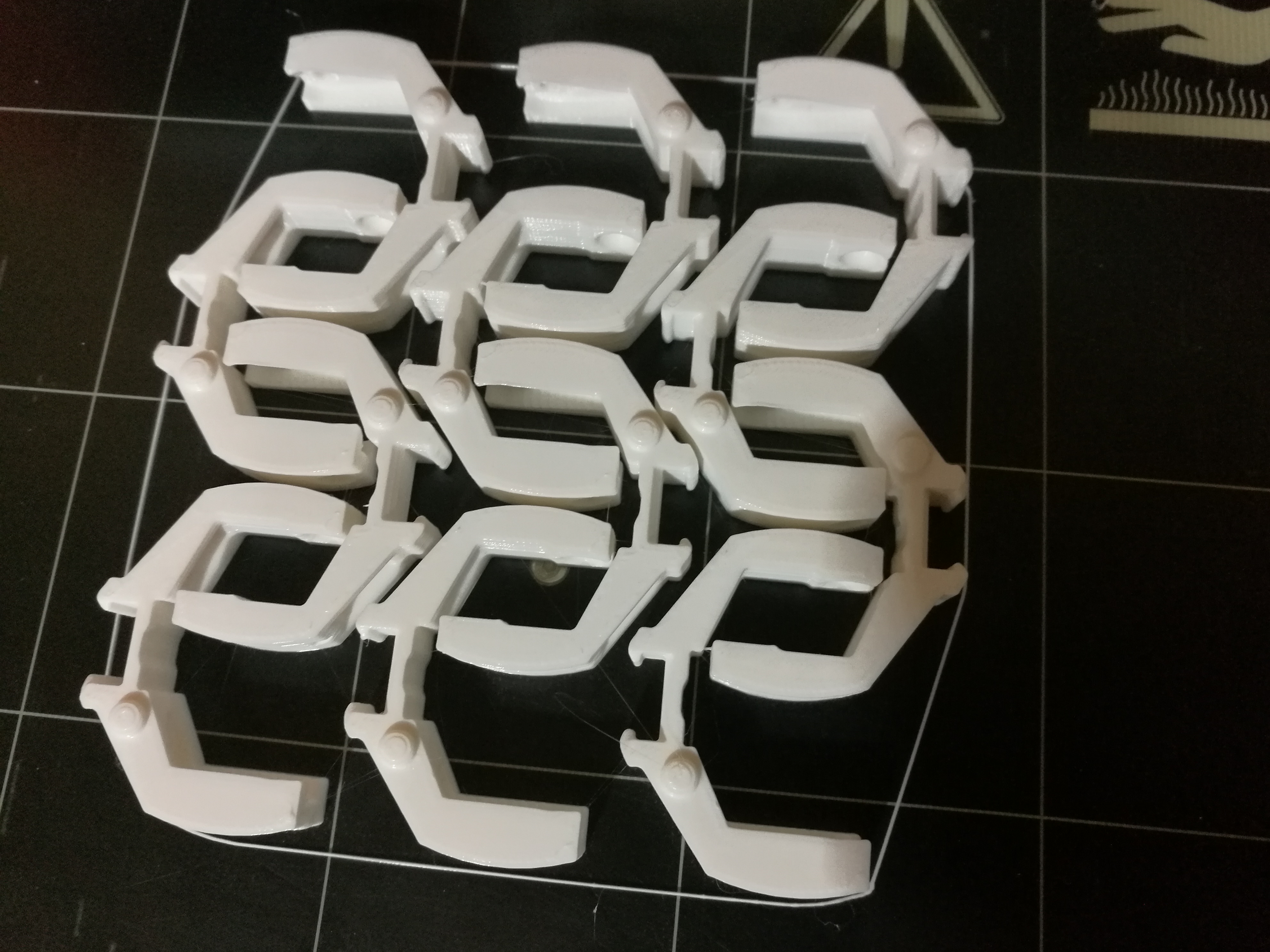

Interesting post, did you receive the very first iteration of the MMU or when did you order it if you care to share? I am asking because after I've set everything right according to this thread my printer prints very well for long times, I printed this 3-colored part for 33hours without blockage:

I unloaded succesfully, loaded different filament and started printing again a different 4-color model - the first three colors were extruded fine in the pre-check phase (when it prints a few lines of every color near the edge) but the last one didn't come out, blockage unter the cooling tube as always. Damnit I thought, this cannot be now? 😯

The difference was that the first three colors were Verbatim and FormFutura PLA but the last one was PrimaValue, it's always a PrimaValue filament if I get a blockage so I figured to hell with it I'm going to trash all PrimaValue filament and never look back.

But now I've stumbled over your post and you report similar issues with a specific filament, yes with a different material but what stands out for me is that you printed succesfully for 24h before and with a different filament you couldn't. Does this mean that there is filament which can work with a "wrong" sized PTFE tube and others don't? I think I'm going to measure out my PTFE tube too if I see blockages happening again with other filament.

I begin to feel like playing whack-a-mole, you solve one thing and then another pops up lol

Re: Blockage troubleshooting.

Rafael.d

I ordered MMU 8/16/17 and received it 10/20/17. I had a lot of blockage issues until reinstalling a new PTFE according to the method PJR had recommended. However, this PTFE was intended for the original MK2S and measured out (later) to be 2.1mm ID. I had mistakenly ordered this PTFE from Prusa and at the time they did not have any PTFE for the MMU in stock. But this new setup worked fine to make a 24 hour 4 color print using Hatchbox PLA . It was not until I tried again to use Verbatim BVOH that I had a problem. It is possible that the Hatchbox PLA is more “forgiving” than the BVOH. I have now installed the “official” Prusa MMU PTFE measuring 1.85mm ID and have had successful long prints using the BVOH. My printer is working well, finally.

Re: Blockage troubleshooting.

Ah okay, thanks for clarifying. I thought that your MMU was delivered with a wrong sized PTFE and that other units might have been too, which it was not thank goodness. In that case I'm going to give the PrimaValue away for recycling and stick to FormFutura PLA 😉