ABS warp

Hello,

I can't solve an issue with ABS so if I can have your advice 🙂

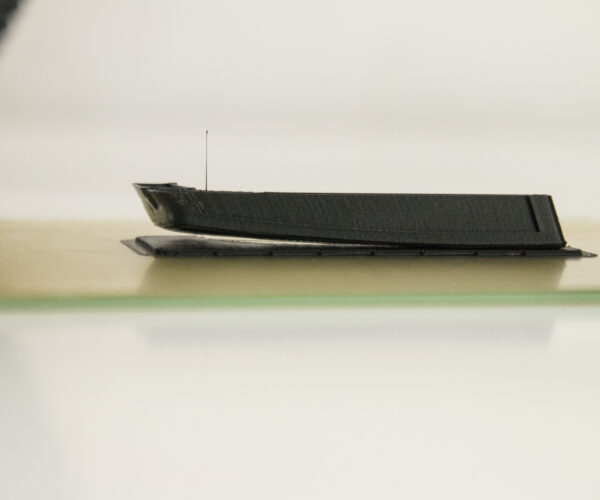

My issue is like all other my ABS piece warp but only after some time and often three out of four angles but one is good..

I use a bag like enclosure not perfect but keep a little heat and not too much heat exchanged directly on the heatbed.

First ABS layer is perfect and following too but after some hours (not stay behind this printer) my piece is warped at the end only on angles and not all.

What I can do ?

- Increase bed temperature from 110° to 120° or useless and even not supported by this 12V printer no ?

- Print at 100% but consume a lot of material ? (or a way with prusa slicer to fulfill only angles at 100% for limiting warp ?)

- Create layers under the piece can help or useless ? I already print brim but brim warp first and angle follow after 🙂

- Nozzle seem way too high for interfere on the first layer.

- PrusaSlicer activate the second fan on higher layer can be that ? (not look how change this parameter)

- Printed parts with ABS are big can be the issue or size change nothing and warp even if smaller ?

I would like avoid glue or tape if there is another way so if someone have an idea 🙂

Thank you for your help

RE: ABS warp

Here are a couple of suggestions, coming from printing many ABS pieces.

First, if you do not have an enclosure, use the draft shield option. It's available in both PrusaSlicer and Cura and will give you a mini-enclosure to keep the heat more stable. If your part is tall, be sure to increase the number of loops so the shield will not collapse and give you a bird's nest of spaghetti.

Second, for all ABS prints and for any prints, actually. Preheat the machine to ABS temperature and let it sit 15 minutes or so to stabilize before launching the print.

You mentioned that you do not want to use glue. I will offer you an alternative. I use this mostly as a release agent for ABS, as I find ABS, if anything, sticks a bit too well. It will most definitely help to control warping and curl-up in the corners. It's the Layerneer Bed Weld. If all you need to do is control warping and curl-up, just place a dab or a swipe of it where the edges and/or corners will be on the plate. I've found that this works well on both the Prusa smooth and textured sheets.

Then there are the usual admonitions, such as being sure that you start with a plate that is not only merely clean but Really Most Sincerely Clean (tm) and be sure that your Z calibration is properly dialed in for the sheet that you are using.

ABS does have a known slight shrinkage factor as it cools, so being sure that you have a bed to which it will stick and stay, and an environment (enclosure or draft shield) to control the temperature decrease as the print progresses.

RE: ABS warp

@jsw Thank you for you very well detailed reply

True I read that somewhere and forgot to search this option in the slicer 🙂

I keep a moment for heat a little my big plastic bag enclosure but may be not enough time so I check time on my next print 🙂

My problem with glue it's not damaging heatbed because seem a fine layer pasted on heating part.

I clean after each print so should be good and can't change sheet so Z should be good too. I take long time to calibrate Z by trying first layer calibration tool and checking angle. Stick seem good but probably not enough.

One angle stick so shouldn't be too far from the right way 🙂

Thank you for your tips 🙂

RE: ABS warp

The Layerneer applies much thinner than glue stick.

If you are really concerned, you can apply a layer of Layerneer (or even do this with glue stick) and buff it a bit with an alcohol-soaked cloth. This will even it out and thin the layer.

RE: ABS warp

@jsw I launch another print after your post :

- wait 15min under the bag at the right temperature

- 50% speed selected directly on the printer for first layer and increase later to 100%

- use the wall in the slicer

A very little warp which isn't visible without turning the part 🙂

I not found Layerneer yesterday yet but I will find !

Thank you 🙂

RE: ABS warp

Hello,

I can't solve an issue with ABS so if I can have your advice 🙂

My issue is like all other my ABS piece warp but only after some time and often three out of four angles but one is good..I use a bag like enclosure not perfect but keep a little heat and not too much heat exchanged directly on the heatbed.

First ABS layer is perfect and following too but after some hours (not stay behind this printer) my piece is warped at the end only on angles and not all.What I can do ?

- Increase bed temperature from 110° to 120° or useless and even not supported by this 12V printer no ?

- Print at 100% but consume a lot of material ? (or a way with prusa slicer to fulfill only angles at 100% for limiting warp ?)

- Create layers under the piece can help or useless ? I already print brim but brim warp first and angle follow after 🙂

- Nozzle seem way too high for interfere on the first layer.

- PrusaSlicer activate the second fan on higher layer can be that ? (not look how change this parameter)

- Printed parts with ABS are big can be the issue or size change nothing and warp even if smaller ?I would like avoid glue or tape if there is another way so if someone have an idea 🙂

Thank you for your help

ABS DuraPro (230/100) printed on the prusa mini without housing on the smooth PEI printing sheet without glue or other aids:

with brim and draft shield it works quite well - almost zero warping 👍

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: ABS warp

@karl-herbert

I have almost no single issue with brim and draft shield and keep a bag like cover.

Thank you at all for your help 🙂

RE: ABS warp

@warnings

I am glad that it works better now. It is not a panacea, but it prevents warping quite well 👍.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: ABS warp

Work very well !

Before I can't print ABS and now no issue I can print almost everything just some parts without support (yes I know :D) have issue but it's ok 🙂

I try to create a closed place for my printer just wait magnet for print all parts.

Just one thing if I want limit acceleration of Y axe only I can just touch "printer settings \ maximum accelerations" and put "maximum acceleration Y" to something like 100 or 50mm/s2. All other settings are adapted ?

When you add weight inside a piece sometime Y loses it's position after some high speed movements due to weight on the bed.

RE: ABS warp

@warnings

The stepper motors have quite a lot of power. I wouldn't change the acceleration values for now, unless you put 5kg on the printing plate.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: ABS warp

@karl-herbert

I have the issue right now. My current printing is just dead giving me a step at almost each layer.. I try to correct but give nothing now and layer can't stay without anything under.

Movement are way too fast when you load so how I can limit movement speed of Y for all type of job during a print ?

Need to print at 15% about for not have issue.

RE: ABS warp

@warnings

The normal Prusa presets in Prusaslicer should normally work well. If you want to reduce the printing speed, it is best to do this in the Slicer.

I would read through the topic Layer Shifting: https://help.prusa3d.com/en/article/layer-shifting_2020

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: ABS warp

@jsw

Thanks for the draft shield trick. I didn't think it would make difference what with hot air rising etc. No quite one for one but printed in ASA with shield without warp something that warped considerably with ABS.

RE: ABS warp

@towlerg

Very true. I jumped on an enclosure when i started but I have gotten good results without by using a draft shield.

--------------------

Chuck H

3D Printer Review Blog

RE: ABS warp

I was struggling with warping ABS so long. Accidentally, when playing with first layer, I might solve the problem.

I didnt find this solution on the internet, Maybe it is known???

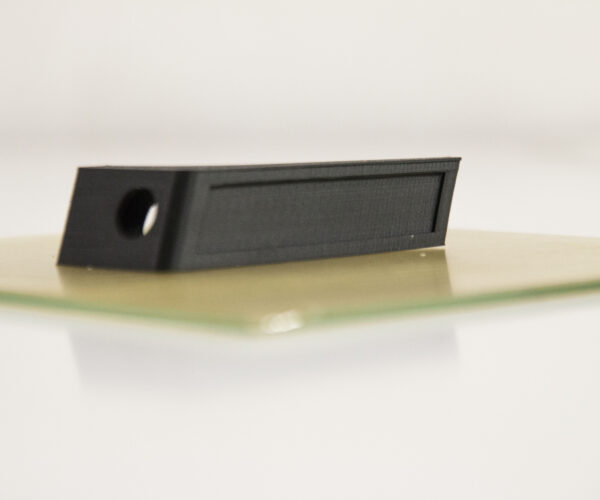

Usually, when I set the first layer to "rectilinear", "concentric" etc., it always warp. But I wanted the first layer with "hilbert curve" and bang, no warping. Even without skirt, brim or raft, there was just a little. And when I added brim, it is perfectly flat 🙂

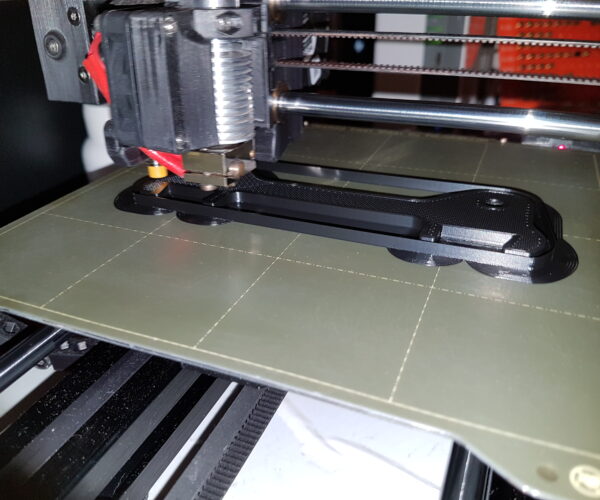

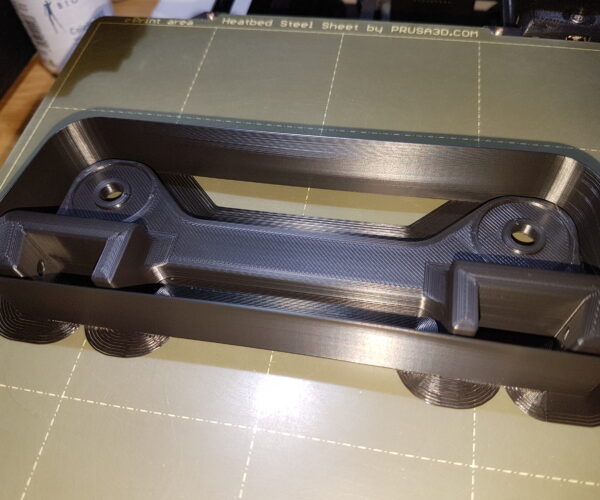

here is print with raft and brim

And here is the same part with hilbert curve on top and bottom layer, no brim or raft or skirt...

I did five tests so far...

Hilbert curve infill