I think I've ruined my printing bed

Hi,

I've received mu MK2 kit on friday, and I've built it on saturday. I've printed some objects for my kids, but I was not satisfied with the alignment of the structure.

So today, I straightened it using a digital calliper, and it as laser straight.

But when I did XYZ calibration something went horribly wrong : on the second calibration point, the nozzle carved the bed :

I've cleaned the mess (parts of PEI were sticking out), and tried to fill the holes with some superglue.

But it didn't work, when I tried to do a XYZ calibration, the first 4 calibration points went fine, but on the second pass, the nozzle carved the bed again, the superglue, even set, does not seem to be a hard enough material.

That leaves me with two options :

1: try to replace the PEI Sheet (which is out of stock on shop.prusa3d.com), hoping the nozzle has not carved the bed too deep

2: replace the whole bed, but I don't know where to get a new one

I really need some help on this, my kids are going to kill me !

Thanks per advance,

Mathieu

Re: I think I've ruined my printing bed

I think I've found the source of the problem : the calibration point on the middle right doesn't register height, that's why he carved the bed during XYZ calibration.

I tried a simple Z calibration, and it went well for the front 3 calibration points, but when it tried to determine the height for the middle right calibration point, the probe didn't stop and forced the bed down. Of course the Z axis was misaligned in the process so it also failed for the remaining points.

So it answers my first question : I need a complete new heatbed for my printer 🙁

Is there a way to get a new heatbed from Prusa ?

if needed, I can do some soldering.

Mathieu

Re: I think I've ruined my printing bed

hi mathieu:

first you have to find the reason for the problem that lead you to ruin your printing bed, otherwise you would ruin a new one as well.

because the first 3 alignment points went well, i assume that you'r assembly is not straight and your printbed is higher at the rear than at the front.

check if everything is perpendicular and that the y-rods sit completely down (fixed with zip ties that doesn't interfere with the y-carriage holder) inside the printed edges.

furthermore: make sure that the 10mm threaded rods of the y-assembly sit completely down in the z-frame and that the M10 nuts are tightened strongly.

when you then know that your assembly is correct and you will have two possibilities:

first: you can replace the pei sheet. a new one costs about 9€ plus twice as much for shipping 😮 .

second: you can ask through the chat at the prusa shop for a complete new MK42 heatbed. shipping inclusive, it will be around 100€.

if your assembly was still correct before the "headcrash", and the problem really is related to a missing or faulty alignment point inside the printbed, then it should be a case of guarantee (but why did you manage to get it running previously ?).

---

but at all i'm really astonished that you've ruined your printbed / pei sheet that severe. normally there is some elasticity at the y-carriage assembly. so a little "dip" of the nozzle to the printbed shouldn't damage it severely.

btw.: what's the height distance between the nozzle-tip of the hotend and the bottom of the pinda probe ? (should be between 0.7 and 1.0mm).

dem inscheniör is' nix zu schwör...

Re: I think I've ruined my printing bed

hi mathieu:

first you have to find the reason for the problem that lead you to ruin your printing bed, otherwise you would ruin a new one as well.

because the first 3 alignment points went well, i assume that you'r assembly is not straight and your printbed is higher at the rear than at the front.

check if everything is perpendicular and that the y-rods sit completely down (fixed with zip ties that doesn't interfere with the y-carriage holder) inside the printed edges.

furthermore: make sure that the 10mm threaded rods of the y-assembly sit completely down in the z-frame and that the M10 nuts are tightened strongly.

when you then know that your assembly is correct and you will have two possibilities:

first: you can replace the pei sheet. a new one costs about 9€ plus twice as much for shipping 😮 .

second: you can ask through the chat at the prusa shop for a complete new MK42 heatbed. shipping inclusive, it will be around 100€.

if your assembly was still correct before the "headcrash", and the problem really is related to a missing or faulty alignment point inside the printbed, then it should be a case of guarantee (but why did you manage to get it running previously ?).

---

but at all i'm really astonished that you've ruined your printbed / pei sheet that severe. normally there is some elasticity at the y-carriage assembly. so a little "dip" of the nozzle to the printbed shouldn't damage it severely.

btw.: what's the height distance between the nozzle-tip of the hotend and the bottom of the pinda probe ? (should be between 0.7 and 1.0mm).

I agree that replacing the PEI or entire bed will not fix the problem. But I do not think it has anything to do with mis-alignment of the physical printer frame.

Remember: Mathieu already printed some objects successfully, but then he thought he could improve the frame alignment for some reason.

To me, this sounds like a variation of the "Nozzle crashing into calibration point 4 of 9" scenario. It finds the same point just fine during the first round of calibration, when it is point 2, but then in round 2, it fails to find the middle-right calibration point at random. Usually, it drives the nozzle straight down into the bed at point 4 of 9, but in this case it seems to have moved X and Y and Z axis in order to scrape deeper and deeper into the PEI sheet.

Nevertheless, I bet this is random and my advice is to repeat the self test and XYZ calibration, but watch (and if possible video record) what happens, particularly the blinking of the red LED on top of the PINDA probe when it gets to point 4 of 9 (or 2 of 4).

Re: I think I've ruined my printing bed

...

To me, this sounds like a variation of the "Nozzle crashing into calibration point 4 of 9" scenario. It finds the same point just fine during the first round of calibration, when it is point 2, but then in round 2, it fails to find the middle-right calibration point at random. Usually, it drives the nozzle straight down into the bed at point 4 of 9, but in this case it seems to have moved X and Y and Z axis in order to scrape deeper and deeper into the PEI sheet.

so if that's the case we have to ask each other: why is there a "weak" calibration point #4, which causes problems at several builds... is it prone to interference with the right z-stepper, or some cables underneath the printbed, or the switching power-supply ?

the pinda probe is an inductive sensor, which operates inside an environment with a lot of magnetic and electric interference sources. so if it fails randomly at a specific point it's most likely that the reason is based on that interference.

there are a few approaches to deal with it: reduce the amount of interfering sources (disable heatbed, hotend and extruder while reading the pinda, only use a low current to drive the required steppers (-> silent mode)), try to shield some of the parts (would be very tricky in case of magnetic interference), improve the noise reduction.

as far as i can remember, the noise reduction is done by software...

dem inscheniör is' nix zu schwör...

Re: I think I've ruined my printing bed

In my experience, and from reading other's reports here, the points at about X240 Y105 and X240 Y210 are affected by random failure to detect them during XYZ calibration and/or mesh bed levelling.

It's not impossible that it might be due to hardware issues, like a smaller amount of metal in the bed at these 2 calibration points, but it could also be due to software problems.

What baffles me about it so far is that the problem is intermittent. I have had at least half a dozen calibration failures that occurred with no obvious explanation. That may well be lack of observational skill on my part, but simply repeating the calibration or mesh bed levelling a few times usually gets rid of the problem. And once it has completed mesh bed levelling or calibration successfully, the printer continues to work well for repeated prints.

Re: I think I've ruined my printing bed

Hi guys, and thanks for your answers,

About the alignment, the calibration worked when the assembly was not straight (I got the "X/Y skewed severely. Skew will be corrected automatically." message).

The current alignment is now near perfect : measurement on each axis is perfect, give or take 5 hundredth of a millimetre on my digital calliper. Visual alignment of the Z axis is also excellent (much better than it was before), and the bed is also level to the table the printer sits on (give or take a tenth of a millimetre).

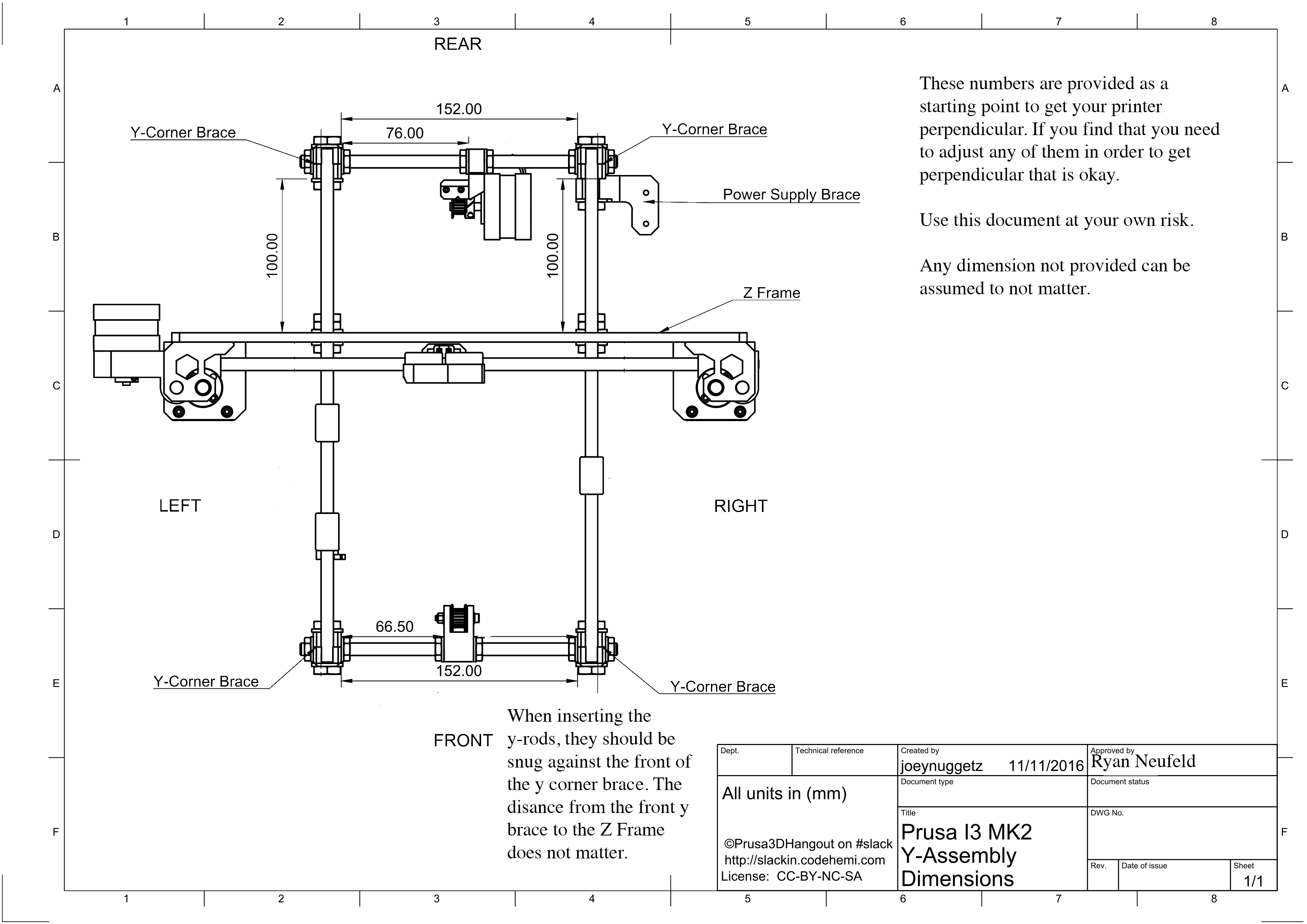

For reference, I used this dimensions diagram :

And about the deep carving, the reason is simple : I left the room for 1 or 2 minutes, right at the wrong moment (damn kids !). When I got back, I pressed the reset button, but it was too late 🙁

I was not aware of this "calibration point 4 issue", so I will try to see with Prusa if it's a case of guarantee. But to be honest, I just want to print again, and if my error of leaving the room during a calibration cost me a 100€, so be it !

And thanks for the info on how to get a new MK42 heated !

Mathieu

Re: I think I've ruined my printing bed

@MrMik:

🙄 from the electromagnetic point of view, there might be the wildest and unlikeliest reasons for this behaviour. 😕

here i never had problems with the calibration that were not caused by a good reason (once a loose bearing and once a loose 10mm nut).

➡ but because the pinda is an inductive sensor and in it's construction very similar to a detector radio with ferrite antenna, any kind of electromagnetic fields might affect its reading.

💡 even the cell phone inside your pocket might cause some interference (ever have heard some cell phone activity from your pc speakers or hifi equipement ?)... and if the circuit path of the heating tracks form some kind of antenna, the problem could even be blamed by that.

@mathieu:

from what i can see from the pictures, it might be that replacing the pei-sheet will do. anyhow: if you order a new mk42 bed, it would be a good idea just to order an additional sheet of pei.... just in case.

dem inscheniör is' nix zu schwör...

Re: I think I've ruined my printing bed

The PEI sheet will be fine for many prints, unless they are so big that they need almost all of the X-axis range.

I would not want to replace the sheet before I know that the printer is not likely to just ruin the new sheet at short notice.

I assume you did not receive a free replacement PEI sheet with you printer? I did not expect one, but found an extra PEI sheet in the box. My kit was shipped literally within minutes of placing the order by online chat in September 2016, but since then, orders have gone through the roof and it seems like they are struggling to meet demands.

Regarding electromagnetic interference causing malfunction of the PINDA probe: It seems unlikely that a mobile phone or other intermittent source of radio-frequencies would affect the function of the PINDA probe disproportionately when it happens to be at point '4 of 9' or point '9 of 9'. Except, maybe, if the frame somehow acts as an antenna, concentrating interference towards those points.

But I reckon' Occam's razor points towards a software issue.