NOOB trying to print tunnel, crash detected and "plastic afro"

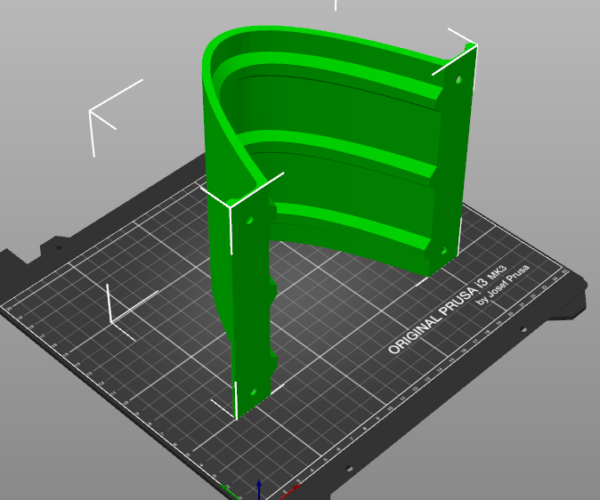

I've tried twice now print this object. It's a 21 hour project. Both times, I return the next morning to see my parts only about 15% completed, and a crazy plastic afro all over the print bed and around the printer. The only error message is "Crash Detected". The part is knocked off the bed.

What am I doing wrong?

RE: NOOB trying to print tunnel, crash detected and "plastic afro"

I noticed that on the 1st attempt, the part has a big bulge, like a button. Perhaps the nozzle crashed into it and knocked the part off, but it didn't get detected and therefore the "plastic afro". What might have caused this big bulge?

On the 2nd attempt, I was getting very substantial warping away from the bed; perhaps that again caused the nozzle to hit the part. How could I prevent warpage away from the bed?

RE: NOOB trying to print tunnel, crash detected and "plastic afro"

What material?

I'm going to bet it's a combination of a contaminated/dirty print bed (search here for how to clean your print bed, it involves dish soap and water and some specific instructions. Bobstro and Tim have excellent copypasta templates on this subject; it just feels wrong for me to copy-paste their effort in writing it, even if I do attribute it to them) and part warping. Thin parts like that are very fond of curling up, especially with warp-prone materials like PETG, ABS, etc.

In addition to a clean bed being critical, use a brim to round out sharp corners where peeling likes to start, and if using some of the hotter materials (e.g. anything but PLA) consider an enclosure or something to keep the drafts down. Air movement will make warping/lifting that much worse from uneven cooling.

If your bed is properly clean, it should hold well enough to even do gravity-defying voodoo like this: (Props to Bobstro for the pic on his blog)

http://projects.ttlexceeded.com/3dprinting_bed_adhesion.html#bed-adhesion

RE: NOOB trying to print tunnel, crash detected and "plastic afro"

Examine the underside of one of your failed prints. Can you see any lifting along the edges where the part may have warped up off the print surface? If so, it's likely that the warping distorted the overlaying layers until it hit a critical level at which the print stuck up far enough to be bumped by the passing nozzle. At some point, it dislodged or the travel was impeded causing a skip which threw subsequent extrusions off, resulting in your spaghetti monster. In some cases, the print will dislodge completely and form a tangle or the "Blob of Doom" encasing your hotend in a deadly embrace of molten filament.

Check for Live-Z and adhesion issues. If Live-Z is off, adhesion will be poor on the 1st layer. If the bed is contaminated, you need to clean it for good 1st layer adhesion. Either one being off can result in this sort of problem.

If the problem proves to be the print itself, you might try printing with a brim to increase adhesion.

RE: NOOB trying to print tunnel, crash detected and "plastic afro"

@bobstro

3D printings "Blob of Doom" LOL, kinda like good old "blue screen of death"

Edit. And "Click of death" on zip drives

RE: NOOB trying to print tunnel, crash detected and "plastic afro"

Hi bobstro and vintagepc

Thanks for your replies! My bed was clean, and I'm using prusament galaxy black PLA. Both of you have confirmed what I thought could have been the problem, after some googling: poor adhesion, and consequently curling up and the nozzle knocking it off, and then spaghetti monster. So I think I'll try with a BRIM, but I also want to build the enclosure before trying again.

I also just tried to print a spool (bed perfectly clean), and witnessed layer shifting on the x-axis; I can't tell if that had occurred while printing the tunnels, 5 and again 2 days ago. But as I got to it and saw the mess, at least on the second time around, I found the x coordinate to be wrong. Maybe the 1st time too, can't remember. So I think I might have dry rods, given that it's under a month old and I bought it fully assembled.

I'll try again with obviously a clean bed, a brim, an enclosure, and lubricated rods.

Thanks for your help