Trying to print part with moving sections.

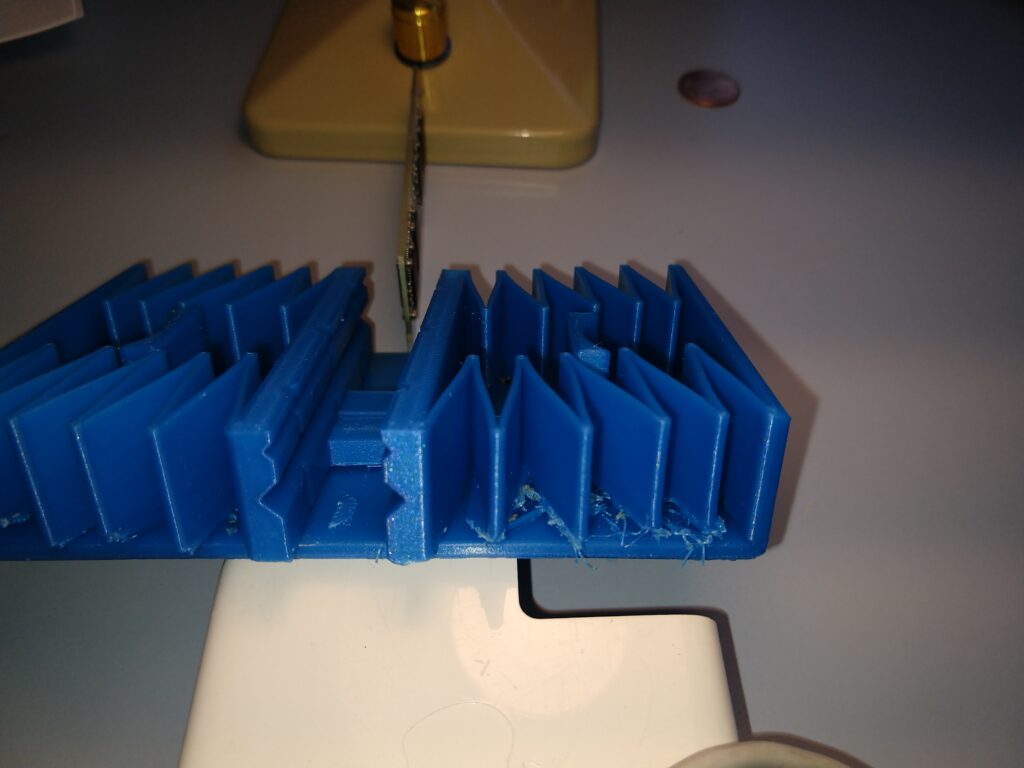

I am trying to print a PCB vise from Thingiverse - somewhat to learn more about printing models with motion. The model has a base plate, skips two layers, and then prints zig-zag shaped springs and jaws. I had a lot of filament pulling when the spring shapes restarted although there was also significant adhesion between the parts that I was able to seperate with a putty knife. I used Prusament PLA filament and then default slicer settings for this material.

I have never tweaked print parameters before and I am looking for suggestions about where to start. Hotter or cooler temps on both bed or extruder, skip 1 or 3 layers, thinner or thicker layers? One user in the comments had adjusted printer speed. Can I slow the speed down for 1 or 2 layers in the Slicer?

Any comment or feedback would be greatly appreciated. As I said, this is a learning part to try single piece moving prints.

TIA.

RE: Trying to print part with moving sections.

Do you use supports for the bottom of the springs?

RE: Trying to print part with moving sections.

I would reconsider the supports. If you adjust the support settings so the interface layer is, say 5 or more mm you might find that the support will break away with movement of the bellows.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Trying to print part with moving sections.

I had thought of supports, but they would be almost impossible to remove in the corners of the springs.

Did you use the default support parameters or adjust them. The ones that have been cited on the forum for good break-away supports are:

0.25mm z distance.

75% xy distance.

3mm support spacing.

4 interface layers.

0.2mm interface layer spacing.

RE: Trying to print part with moving sections.

Thanks. I will investigate that idea.

RE: Trying to print part with moving sections.

This video, about this design, or one very similar, might be helpful

RE: Trying to print part with moving sections.

@gordon-w

Actually, that video is where I started. I like the idea so I downloaded the file from Thingiverse and started. I mostly used the stock Prusa settings for my Mini and Prusament PLA. In the video, his layer thickness was 0.28 on his Ender. I left the my layer setting at the stock 0.15. I recognized that I might have more adhesion, but in fact my issue was too little adhesion across the gap so I would expect that increasing layer thickness would hurt, not help. On the other hand, the thicker layer would lay down a larger string of material so it might stay in place better. That's a point I hadn't thought of until now, so if anyone has experience please chime in. As I said, this is primarily intended as a learning piece, so I may give thicker layers a try after I play with supports.

BTW, the designer replied to me on Thingiverse that he wasn't aware of others having the issue I had (I posted there as well).

Does anyone have comments about temps? Again, I left my settings at the Prusa recommendation for their material - 215 extruder and 60 bed.

Thanks again for the responses.

RE: Trying to print part with moving sections.

@puetz

I have just had a go at this using the ideas of @jsw for support. This is it straight after printing (sorry about the brown filament!):

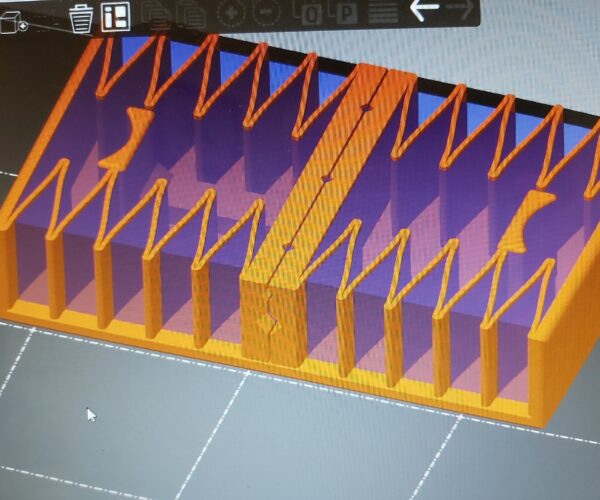

The changed settings for the mini were 1) layer height 0.3mm and 0.35mm - only because it speeds it up by 3 hours. I do then slow down to 90% speed and 90% flow factor using the manual settings (the flow factor has to be set just before printing starts or the program overwrites with its own setting of 95%). When slicing I couldn't use the 0.25mm Z distance because the support material was everywhere except under the spring! So I put it back to the default 0.1mm. I also changed the interface pattern spacing to 0.4mm (from 0.2mm). This had the effect of thinning out the support so there was less to remove - it pinged off with tweezers. I think I got it all out from under the springs.

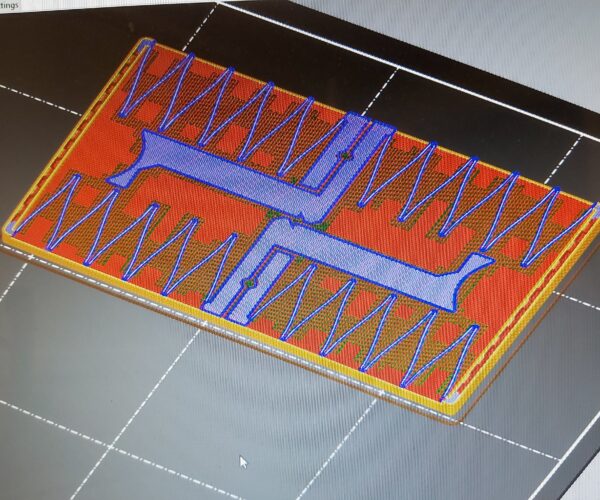

When I did the slicing, initially I had automatic support on - but this created all sorts of unneeded support round the edge. So I unclicked "autogenerated support" and clicked on "generate support material" and then right clicked on the model to add a support enforcer box. As shown below:

If I were to do it again I would try and go right to the hinge points. That gave me a support pattern like this:

Although this generates all sorts of unnecessary support around the vice faces, I found it easily separated and pulled out with tweezers.

Only one problem - I was a bit rough with the end of the push rod and the bit where you put your finger broke - so I have glued it - wrong to use only 15% infill default I think.

There you go - a nice project to expand my newbie skills - and useful.

RE: Trying to print part with moving sections.

@puetz

😀 I too saw the video and downloaded the model, but haven't got round to printing it yet, so watching this thread with interest. It looks like @kim-1 has found a good support configuration so there is hope!

RE: Trying to print part with moving sections.

I guess it is fun to pull a print off and have it work straightaway, but it seems like this model would be a lot better printed in two parts. If you have to fiddle around removing support, gluing a couple of parts together instead seems like a good trade-off.

RE: Trying to print part with moving sections.

Hey everyone - thanks a million for the helpful suggestions. I applied supports with an enforcer box, parameters adjusted per the above recommendations. It printed very nicely, with just a couple of rough corners. It took some scraping, but all of the supports came off nicely.

Goals achieved - I dug more deeply into PrusaSlicer, learned a lot, and have a handy gadget.

RE: Trying to print part with moving sections.

Very nice. Congratulations.