Silk Rainbow filament crisp result

Hi, im one month new at 3D printer.

i have print some clay cutter couple of weekwith Esun PLA + and not have problem.

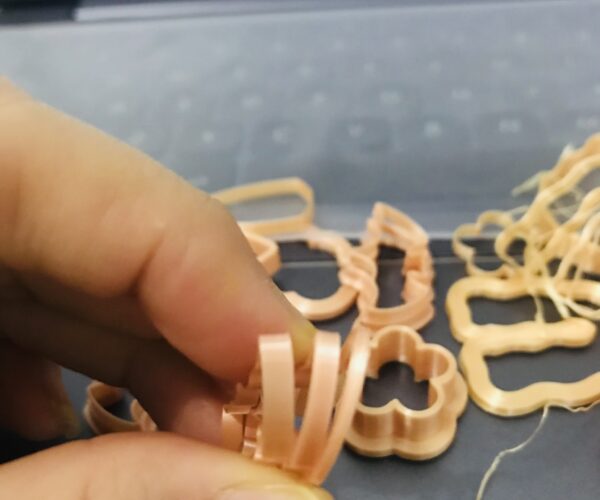

Today i change filament into Esun Silk Rainbow PLA, and the result is crisp, the cutter is consist 3 layer (base, wall, and edge) these 3 part doesnt stick well, everything comes off.

any suggestion for slicer setting?

im using 0.4 nozzle, try 210~230 nozzle temperature, 58~65 bed temperature. And none working

RE: Silk Rainbow filament crisp result

I have actually printed this with prusament slicer setting and it does turn out good. For longer/more detailed projects, I noticed it becomes more brittle. I tried to dry the filament using sunlu s1 filament dryer and noticed increased quality with my prints. Are you storing your filament with silica gel?

RE: Silk Rainbow filament crisp result

I've had this often with TTYT3D Rainbow filament.

Even with NEW just opened, so I don't "think' it's moist filament.

I've been printing at 215/210' would that make a difference?

Silk filaments work by slightly foaming as they print, this gives them their characteristic look but at the cost that they are not so strong. They look good but they are generally less suitable for functional parts.

Generally they need slightly higher hotend temperatures, check the figures given on the spool.

Cheerio,

RE: Silk Rainbow filament crisp result

That is good to know and that does explain why it was so brittle. I made a light saber and as soon as I flung it out… the print just crumbled. Learned my lesson!

RE: Silk Rainbow filament crisp result

Silk filaments work by slightly foaming as they print, this gives them their characteristic look but at the cost that they are not so strong. They look good but they are generally less suitable for functional parts.

Generally they need slightly higher hotend temperatures, check the figures given on the spool.

Cheerio,

I've had issues with the Mika3D silk metallic filaments jamming in the extruder at times.

IIRC, they say the print range is something like 200-230C, with a suggested print temperature of 220, but I've found I get best results printing around 225.

The issue has been more significant on my other printer, Ultimaker S5, as it defaults to 200C for printing generic PLA.

I've also discovered on the Ultimaker that PETg filaments need a bump in the temperature as well above the Ultimaker default, or else the adhesion between layers is poor, similar to the way one of your samples above looks.

I made a light saber and as soon as I flung it out… the print just crumbled

Use the force...

Cheerio,

RE: Silk Rainbow filament crisp result

this is new filament just open from the box. i call seller and they send me new filament (i request to send me PLA+ instead)

PLA+ worked fine. well i just gave up for this Silk filament