Second layer trouble

Hi all,

After having used my first Mini+ for a couple of weeks without any trouble, I'm getting increasingly frustrated right now. I'm trying to print a litophane, but while printing the bottom layers the extruder started clicking and I seemed to get a blocked nozzle. Thinking this might be due to heat creep because of the slow first layer, I reduced the number of brim lines to get to the second layer quicker.

I performed a cold pull, cleaned the extruder, did some more troubleshooting, played with infill settings, performed Z-adjust several times over but to no avail. The "my way" Z-adjust file gives a perfectly smooth first layer.

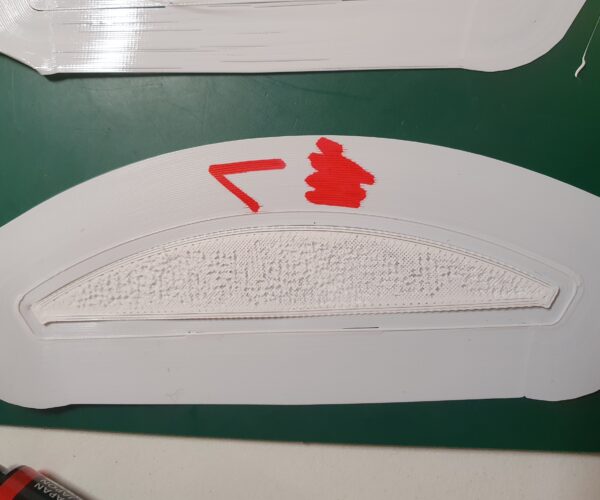

Now when printing my file, I seem to get either underextrusion or, as seen in pictures 2, 3 and 4, some kind of overextrusion near the middle where the nozzle drags over a much too thick part of the print.

I have included the 3mf as a zipped attachment.

Printing with Filamentum white PLA at 210 °C with 60 °C bed.

Any advice / ideas?

RE: Second layer trouble

Apparently the zip file couldn't be attached, so I uploaded a copy to my OneDrive instead.

RE: Second layer trouble

Hi. By coincidence I just printed my first lithothane. I used 100% infill, a brim and supports. The main features came out well but there were a few minuscule blobs, hence dark patches, on the plain white background section of the lithothane. The extrusion on the relief part of the print was near perfect. I needed some white PLA in a hurry and used new Sunlu PLA in white.

RE: Second layer trouble

Okay so I performed some testing with the Prusa logo pre-loaded file, and got similar results. So it doesn't seem to have anything to do with the slice file, but seems hardware-related.

Can anyone explain how tight the extruder idler screw should be, exactly? I found various explanations online but they all seem to differ somewhat. Without any filament loaded, I tightened the screw until pushing the idler door didn't move the screw anymore (about flush with the casing).

This seems to have helped somewhat, but I still seem to get general underextrusion. Any other ideas?

RE: Second layer trouble

What's your "my way" z-adjustment?

Since you have a MINI+, your printer has the SPINDA so that rules out inconsistent first layer height from the older MINDA sensor.

Just from looking at the pictures, it looks to me you are having over-extrusion in general. But you manage to get a decent first layer, compensate by having the Live Z level too high.

My suggestion would be to start with the default filament profile and follow Prusa's Live Z adjustment step, using the First Layer Calibration process. Once that's done and you get a good first layer, THEN you can play with other settings to fix over-extrusion in other layers.

RE: Second layer trouble

My idler screw is adjusted according to Prusa advice. The top of the screw is level with the casing.

RE: Second layer trouble

Thanks for all the advice, After reading some more, trying some other things, almost giving up - rinse & repeat - I decided to thoroughly check the hotend and to put in the spare PTFE tube. The spare tube was almost 1mm longer than the original one, although this might be due to compression of the original tube maybe.

Anyway after replacing the tube the problems seem to have disappeared.

RE: Second layer trouble

Thanks for all the advice, After reading some more, trying some other things, almost giving up - rinse & repeat - I decided to thoroughly check the hotend and to put in the spare PTFE tube. The spare tube was almost 1mm longer than the original one, although this might be due to compression of the original tube maybe.

Anyway after replacing the tube the problems seem to have disappeared.

It seems common for them to shrink, so you can either treat them as a disposable part and make lots of spares, or invest in a Bondtech heatbreak which fixes this issue.

Good luck!

RE: Second layer trouble

Thanks for the tip. You're talking about this heatbreak, correct?

RE: Second layer trouble

@avh yes, that's the one!