Inconsistent results with stock profiles.

For the most part, I get decent results from my Prusa Mini... however, using the Prusament PLA stock profile for my mini with Prusament Galaxy Black... I get really bad vertical surfaces, like the extrusion varies or something. I've noticed this before, and tensioned my belts, but it pops up kinda randomly.

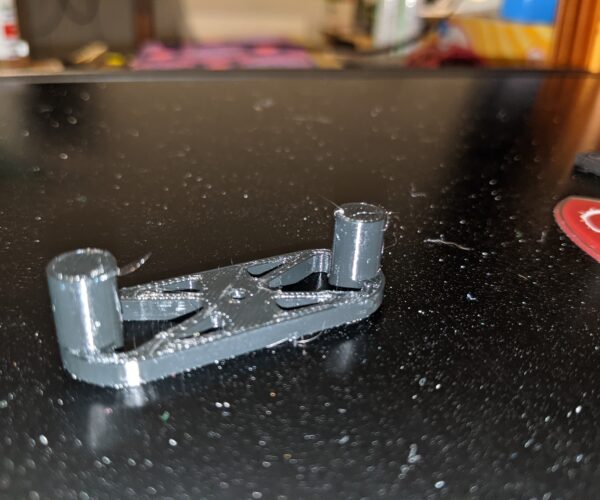

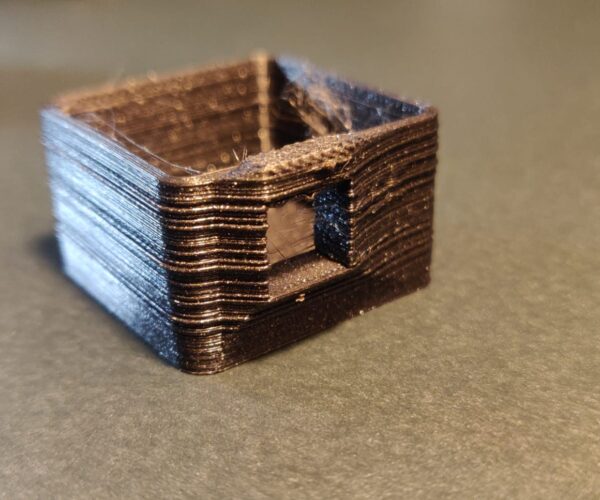

Today I printed a lot of simple prints that have a lot of small, vertical protrusions... This one was printed with Overture PETG using Prusament PETG settings, 0.2 quality. I use the Prusament setting to run hotter and get better adhesion for functional stuff like this.

Vertical finish was great on the cylinders, pardon the dust on my laptop lid, the flash really shows it off. These results are about what I get with 3rd party filament in general.

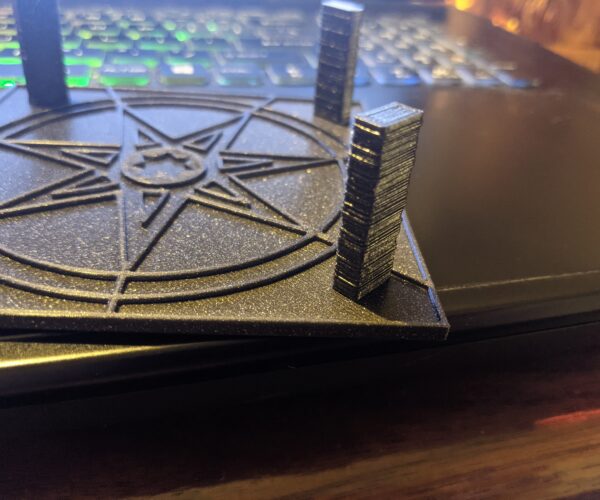

Afterwards, I swapped in the Prusament Galaxy Black PLA and sliced with 0.2 Quality Prusament PLA settings aaaand... I get this garbage on the vertical towers, notice the rest of the print seems fine, even the sides (albeit small) are nice and smooth.

I've encountered this before on circular objects as well using the exact same settings. It seems to happen at random, sometimes it'll be great, sometimes... this.

I've checked my belt tension (trying to reduce Y axis noise), I have a bearing for the spool holder (I use a side-mount instead of the rollerskate now, though I got these results when I used the rollerskate before), and I have a Bondtech heatbreak + PID in the GCode for it. I just, don't know. This happened before all of this (when it was fully stock) and after the light things I've done... Again, this only happens with the Prusament PLA... I have Eryone Galaxy Red that I print with the Prusament PLA settings and it's flawless, did a tolerance test spinner and the 0.15 was free no problem... However if it did this, they'd be locked solid.

I even bought a dehydrator and ran all my filament through it for 6-8 hours apiece to rule out moisture. I've got a couple test prints going right now to do some tests and will post images of them after they finish.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Inconsistent results with stock profiles.

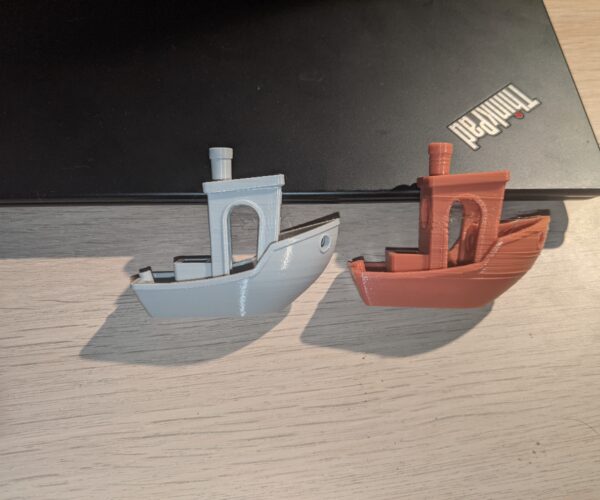

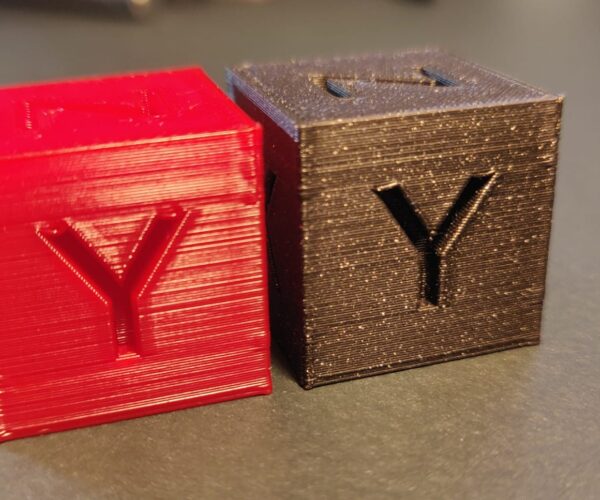

I printed some test pieces, one includes the bracket I printed from PETG pictured first, and a quick throw together to mock the rectangle in the bad image. They were printed at the same time using stock 0.2mm quality, Prusament PLA, Mini+ (except the M301 PID for the Bondtech heatbreak).

One set was printed from Prusament Galaxy Black and the other from Eryone Galaxy Red. One immediately after the other, using the exact same gcode (I've attached the gcode to this post).

The bad layers are quite apparent on the Prusament, but the Eryone is perfectly smooth. If anything, I would expect the OPPOSITE of this to be true, especially using Prusa's supplied profiles for their own filament on their own machine...

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Inconsistent results with stock profiles.

Bah! Edit time expired.

Apparently the forum didn't like attaching the gcode file, since it seems to have just vanished despite attaching it so I dropped it on my google drive, link below. All it prints is that little center finder tool and the little block as I stated above and the settings.

CenterFinder125_0.2mm_PLA_MINI_36m.gcode

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Inconsistent results with stock profiles.

The forum only accepts a very limited number of file types. Stl, gcode and 3mf NOT being on that list. Its why we ask people so zip into an archive any project files as it does accept zip files.

Looking through gcode isnt going to help most people as its not exactly designed to be a human readable format, even if you turn on the verbose output options in Prusa Slicer. Also given that it prints fine with a different filament then there is nothing wrong with it.

Its much better to attach your saved project (3mf file). Someone can load that into the same version of PS and then have access to the exact same setting you used to slice. They can check every one of them if they feel like it and slice and look at the preview.

It could be something as simple as the prusament is 'slicker' so needs a different tension on the feed gears. As you say, you would expect prusa filament using a prusa machine and prusa profiles to work better, so that's why I would be looking for subtle physical differences.

I've only run through about 6 prusament spools so far and I have had to run them hotter than expected or I get under extrusion and eventually clogs on my MK3 (this was with Mystic Brown).

RE: Inconsistent results with stock profiles.

@skreelink I have a similar problem. Was actually going to post it for help and found yours 🙂

In my case it is all Push Plastic PLA the only difference being the color. As an example I printed the benchy with two spools, one light gray and another one terracota.

Honestly I am a little lost in here. I have been doing some sensitivities, but I had no luck. In my case when the "banding" happens it clicks, like if the extruder was blocked and cannot push filament through. I tried increasing the temperature in case the color was modifying the melting point of PLA (up to 245 from 210 that the grey one uses) and made no difference. I noticed that it only happens when the printer retracts a lot... tried adjusting the tensioner but again no real difference.

I have disassembled and cleaned the extruder gears, lubricated everything, checked my belt tension... Honestly the printer has never been so well maintained.

Any opinions or ideas are welcome

RE: Inconsistent results with stock profiles.

@neophyl

I've read about the Mystic Green thing before, it's likely similar to silk type PLAs. The polymer blend to add the shiny or color change makes it thicker and requires higher temps. I tend to run my silk pla at about 220 and reduced retractions. Still bugs me when purging it comes out as a thick noodle instead.

I've adjusted my extruder tension as well, no change.

@aurru

Your MINI is completely stock, correct? No modifications?

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Inconsistent results with stock profiles.

@skreelink

Mi MINI is not stock. I installed the bondtech heartbreak shortly after receiving it (I think I received mine around early May and installed it in June-July after the jamming started) and on Friday I installed the new PINDA probe. I have had no issues related with it until now.

I didn't mentioned before but I printed the grey benchy right after the terracota one to discard any issues with the printer. So I am pretty sure that the printer works as intended.

I am printing a flower vase right now (I know it is a print that barely has any retraction in it) so tomorrow we will see how it printed since it will take the entire night. I was also reading about the mystic green issues that you mentioned and tomorrow I will try by tweaking the retraction values to 0.3-0.4 mm to see if that helps.

RE: Inconsistent results with stock profiles.

I am still struggling with trying to get Prusament to print decently... Cheap filament prints absolutely beautifully. These were printed back to back with the same filaments as before.

Prusament Galaxy Black:

Eryone Galaxy Red:

The Eryone print is so smooth it feels really weird. Both examples here were printed with the "0.15 Quality" preset on my prusa mini. Using the Prusament PLA profile for Prusament, and Generic PLA for the Eryone. Currently I have a temp tower going on the Prusament to see if any heat cleans it up. I did a temp tower with CC3D Marble and Silk Purple, and neither really cared what temp I printed it, it was nice down the spectrum from 195-230C @ 5C increments. I should have kept them to reference here in images though... I'll print another one to compare later.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Inconsistent results with stock profiles.

Did you ever find the reason to your symptoms?

I'm having some very very similar issues with prusament galaxy black lately.

Especially nearing the end of the spool, this stuff just goes bonkers on me.

It started on the stock Prusa mini+ where I couldn't find the reason.

I then changed over to bondtech extruder + E3D, problem disappeared (or got way less obvious) for a while, but it eventually started to happen again.

In this case: Stock Prusament PLA profiles, 0.25mm nozzle, 0.1 layer height.

White printed right before black.

RE: Inconsistent results with stock profiles.

I put the stock heatbreak back in and it's been printing fine ever since, only change from stock now is a 0.4mm NozzleX.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Inconsistent results with stock profiles.

Nice that you were able to get rid of it again. I'm on revo so switching the heatbreak won't be possible.

I contacted support today. They told me to print a calibration cube in galaxy black and a filament that 'works' for me.

So, surprise surprise, the cube printed quite well. No difference between filaments.

Thought, well... perfect. Maybe it was a clog and changing filament cleaned the nozzle.

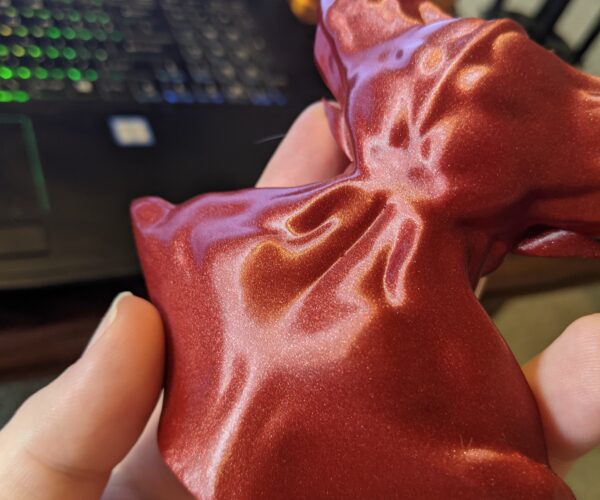

Went back to my previous print.... looked promising on the first layers... but... oh no no no no no:

Changing back to the red filament, as if nothing happened of course:

I can't think of a logical explanation to that behaviour.