Help with Collapsing Supports

I am looking for advice on what to try next with my support collapsing issues.

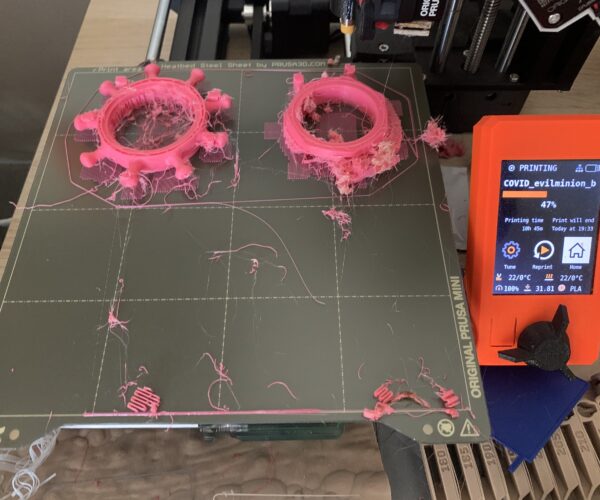

I am a relative Newbie to 3D printing. My supportless prints turn out excellent but my supports keep breaking away from the 1st layer often leading to a spaghetti mess. Nothing I have done so far has made much if any impact on correcting the problem

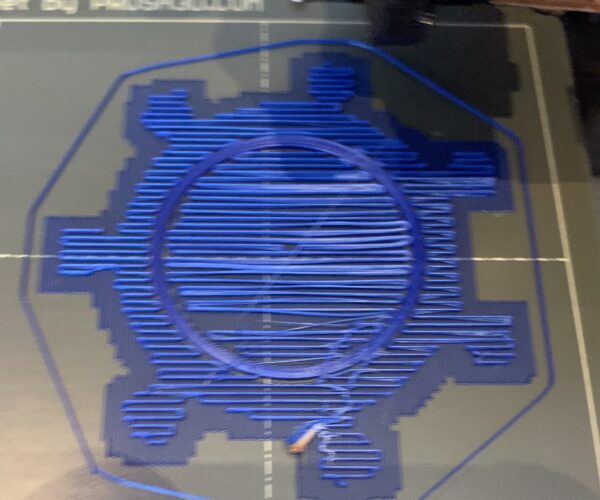

(I know this print has a lot of supports but I get the same issue with prints where only a few supports are needed)

(I know this print has a lot of supports but I get the same issue with prints where only a few supports are needed)

It starts something like the next picture and sometimes with luck the print continues on successfully printing on top of the lower broken away pieces, sometime not.

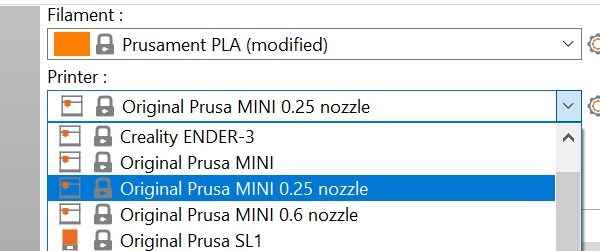

My Printer is a Prusa Mini with a 0.25mm nozzle also from Prusa.

Slicing with Prusasclicer latest release using default settings for 0.25 nozzle, generate support material ticked.

Printing PLA, Prusament and different 3dfillies filaments.

Tried doing cold pulls, disassembling hotend and checking PTFE tube in hotend is good.

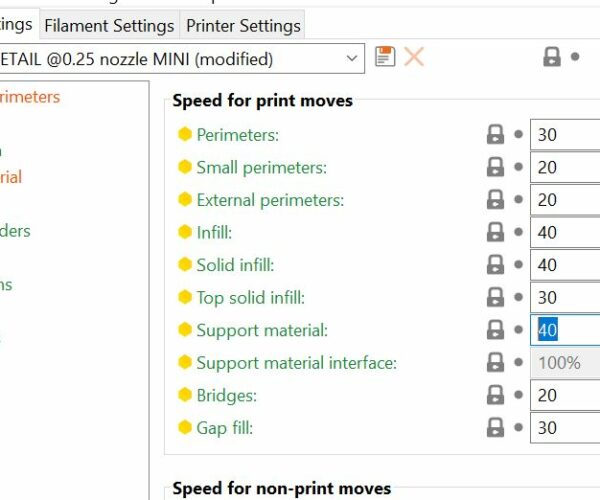

Also tried dropping support print speed to 10mm/s.

Tried all the different built in layer heights for a 0.25mm nozzel and different bed and nozzle temperatures.

So please some advice on what to try next? Could some other of the options in Prusaslicer help me?

RE: Help with Collapsing Supports

Good afternoon nilbogaus,

are you using the latest firmware on your printer?

Have you tried a temperature tower for your printer? (I expect you would need to create your own, as I have not seen one ready made for a 0.25mm nozzle...(however I have not looked for a 0.25mm one either))

are you using the mini 0.25 nozzle profile in Prusa Slicer?

Have you tried slowing the print speed down? either on the LCD menu's or in the slicer?

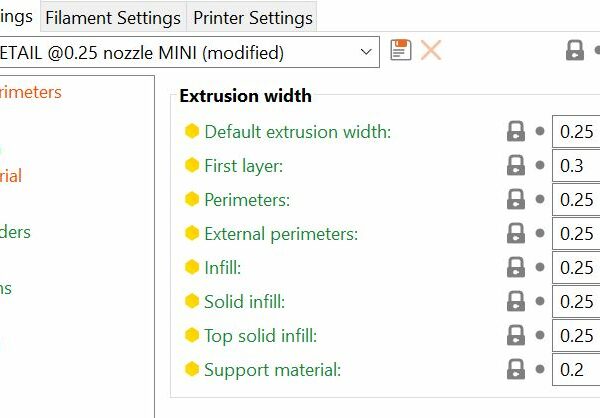

Note, these are Intermediate settings in prusa slicer so you need to select intermediate mode or expert mode to see them.

Have you considered increasing the extrusion width for support a little to help make it more robust?

note support is normally made thinner than the normal print extrusion width to make it easily removable, Yours keeps falling over, so perhaps it's a bit too easily removable... perhaps 0.23 will be a better option for you? or maybe 0.25mm... do a small test print and give several settings a try...

again, these are intermediate settings... you need to be in intermediate or expert mode to see them.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Help with Collapsing Supports

Thanks for the suggestions Joan,

In particular thanks for the suggestion for changing the extrusion width. Its an option I had not even found yet and will be the next thing I try.

I have tried the other setting (speed, nozzle and temp tower) but I will double to make sure they are correct

RE: Help with Collapsing Supports

Thanks again for the help Joan, your idea solved half the problem. With increasing the extrusion width to 99% my supports stopped breaking away at the bottom. Excellent!

Then they started getting knocked over shortly after the item started being printed on the top of the support. Fortunately I was able to fix this myself by adding support interface layers, and then it all worked. Yay!