RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

The same thing happened to me after using a higher printing temperature PTEG - no problem with PLA.

I replaced the Bondtech tube with the correct length of leftover Capricorn tubing. Other than the Capricorn is much harder and stiffer and therefore difficult to cut a taper on ( I gave up and sanded the taper) it has not changed length since. I think Prusa and Bondtech are using a lower quality PTFE and it shrinks a little over time and at higher temperatures.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

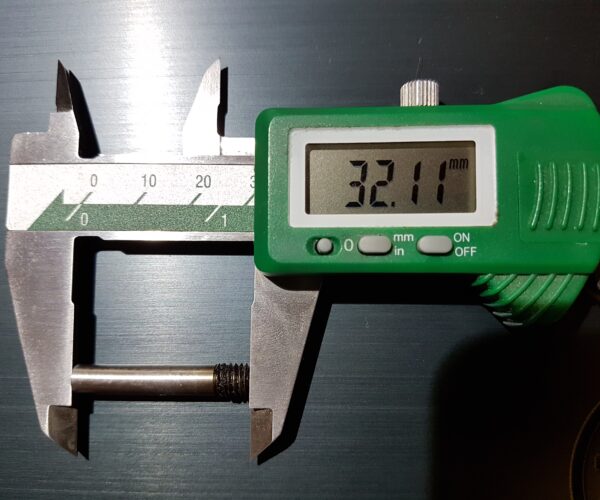

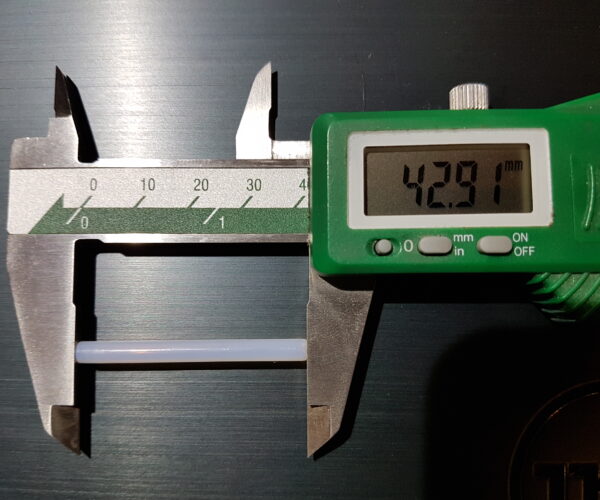

I just pulled my Bondtech PTFE liner out and it is 35mm versus the 35.3mm it is supposed to be. Has anyone else had the Bondtech Heatbreak offer shrink. Is .3mm enough to be concerned?

I have been using my Bondtech for a few months now, and on the two occasions I've had issues enough to start taking apart the hot end, I've measured the tubing and both times it was 35.30-35.40. I think the website says it should be 34.5mm. Mine isn't shrinking though and I think the point of the design for this heatbrake is to not expose the tube to as high a temperature as the Prusa one so it shouldn't shrink.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I bought a Bondtech heatbreak and thermal paste and am reviewing the installation instructions ( https://support.bondtech.se/Guide/0.1+Heat-break+Upgrade+Kit/60 ). For anyone who has followed these installation instructions:

- What is the purpose of Steps 41 and 42? What are the PID parameters?

- Step 40 says that these steps do not work for Prusa MINI Firmware 4.0.5. I currently have Firmware 4.2 installed. What is the current status of the instructions to update the PID parameters?

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@tealbert

There are a number of threads, such as this one https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/bondtech-heatbreak-any-good/ ,where you may find assistance. Fundamentally you need to adjust the settings of the printer to match the changes from the stock item to the bondtech one. You still can't store the parameters in the eeprom so you need to add the code to the 'start gcode' in your slicer.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

is the dual extruder, capricorn tubing and improved bondtech heatbreak the kind of thing that would be integrated into an official mk2 mini upgrade kit?

if so, how long did it take for the first i3 kit to get the available upgrade?

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Prusa is now mailing me a replacement hot end assembly for my Mini. I’m hoping it fixes my clogging and clicking issues, at least for a while. If not, I’ll likely return it (I have 30 days left in my initial tryout period) and upgrade to an I3 Mk3. So far, I’ve had about a 75% operational rate (25% of the time taken apart trying to fix jams) for the first month, printing nothing but Prusament PLA.

Fingers crossed.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

So has Prusa even responded to all this negative feedback on the mini? I have four at work that has the same problems 🙁

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

There was a comment made in the chat during the last live stream (by a Prusa employee) that there would be a an update in the next few weeks, but nothing definite. One of the issues is that whilst some people who have issues, there are others (including me) who are lucky enough not to experience the problems and nobody has been able to work out what's different.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I spent two hours disassembling and replacing the hot end assembly on my one month old Prusa Mini, and now it’s printing well again. Looking on the bright side, I’m no longer a stranger in how to tear this thing down and rebuild it.

One issue I did run into was that my heater element was fused hard into the heater block, and no amount of force I applied (I stopped just short of getting a hammer out) would break it free. So, thankfully Prusa had sent me the full replacement assembly, and I was able to replace it all (along with re-rerunning all the wires). I will probably order a spare set of hot end parts just in case.

After I removed my old hot end, I did notice it did still have PLA residue inside that was causing the extruder jamming and clicking. I had done 5-10 cold pulls and even more hot pulls, plus lots of acupuncture needling, but still there was residue. Sigh. I’m not sure what else I could have done to clean this thing.

In my case the big clog happened the first time I tried a print that was >24 hours in duration. Perhaps this was some form of heat creep issue... Perhaps these printers just clog sometimes. I don’t know.

In the meantime I’m just ordering some contingency spare parts, and resisting the urge to do any third-party upgrades. I did briefly look at the Slice Engineering stuff, but it added up to ~$200 US, and for that cost I could have almost just purchased the I3 Mk3S. So... no.

Hopefully, in a few weeks we’ll have something official.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@marek-w6

original Prusa Mini hotend parts:

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

So has Prusa even responded to all this negative feedback on the mini? I have four at work that has the same problems 🙁

I've talked to support on three separate occasions now... they're varying levels of friendly, and every time have insisted that my mini is fine and I just need to tune settings in the slicer. I showed them the giant bucket I have of test prints changing one slicing setting at a time, and the best they could really offer was "try changing the print temperature."

I'm pretty close to returning this thing. Very frustrating.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

For me the bond tech heat break improved things, but I still had issues. What 100% guaranteed will fix the issues is switching from an all-metal to a PTFE-lined hot end, like the E3D Lite6. You can replace just the heat sink (which is only like 6 bucks) and keep the Mini heater block and nozzle if you do this swap. I wrote a blog about it here: https://www.reddit.com/r/prusa3d/comments/l3jgpa/guaranteed_fix_for_your_prusa_minis_extrusion/

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@wouterv

Someone had a similar thought to mine:

https://www.prusaprinters.org/prints/42554-original-prusa-mini-e3d-v6-hotend

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@3dprintedgr

Why buy a cheaper printer you are going to fight with for months just to keep it printing when you can buy a Prusa and a $15 part and have it printing for years hassle-free?

--------------------

Chuck H

3D Printer Review Blog

updates ?

How did people get on with their heatbreaks and issues. any updates ?

I looked into the revisions posted in one of the posts in this thread but wonder if any would contribute to helping solve any issues since.

Updates

I eventually just returned mine to Prusa and took the refund. I did nothing but continually take mine apart and reassemble it, trying to chase what the problems were. It was an incredibly educational process, but not one that was particularly enjoyable or that resulted in sucessful 3D printing. I resolved to go find other hobbies for ~5 years or so, then come back and check to see how it's going. Right now, either the technology or I am not ready.

RE: My Experience (36 printers)

I print for profit, and own/operate a 105 strong 3D printer farm. I've been an Engineer for 24 years (RF, Electrical, Software, Embedded Systems) and printing for profit for about 5. I sell around 10,000 prints per year processing around 100kg a month.

I bought 4 minis to test when they were first announced, and I was happy with the results. This was around October, so I didn't get them until around December. I ran them for a couple of months, liked them, and bought 32 more to be fielded in 2 new racks. When printing at scale, the Mini became my most hated and frustrating machine, plagued by problem after problem and costing me time and materials along the way. I was operating 19 Prusa MK3S+ at the time, and I expected the mini to perform similarly as it was advertised in the beginning as a print farm compliment.

Issue #1: The original MINDA probe wouldn't hold a first layer cal for repetitive printing. My shop (used to, not anymore since HVAC install) varied from 50F to 88F. Depending on the ambient temp, the probe would drift to the point it would reach the software imposed 2.0mm stop and would have to be mechanically aligned to the current ambient temp. This led to a lot of bed detachments and clogged nozzles/clogged extruders. Luckily, the "Super PINDA" addressed this issue, and after a long wait I was able to source 36 for the farm and get them rolled out. All in it was another $1,000 investment and about 40 hours of labor.

Issue #2: Random serial disconnects. I control over octofarm/octoprint, and every once in a while after a few days of printing the machine would stop responding over serial leaving a hot machine and a failed print. I ran a couple of tests and isolated the issue, and a power cycle after every print along with the plugin "portlister" and the issue has been resolved. The testing consumed 2 hours of my time, and the power cycle adds 2-3 seconds to the harvest of every print. I may look into running a test in which a reset is sent by octoprint after every completion. If that works I'll amend my recommendation.

Issue #3: Extruder bearings in the stock extruder failing after 200 hours of printing. This is compounded by issue #1 above, and probably could have been lessened had I started with the new probe. Powdery filaments such as HTPLA (ProtoPasta) slough off when under stress (partial clog, bad first layer, unseated PTFE, etc) into the internals of the stock extruder. With no exit path the fine dust works into the idler bearing and 5:1 gear bearing, creating additional friction on the filament path. This drastically reduced the reliability of that machine until the extruder was rebuilt with new bearings. I abandoned the stock design an ported over the MK3S+ extruder and integrated filament sensor. This is a much more forgiving extruder with the dual-gear design, and will continue to push even under stressed conditions. All in I invested $40 in sensors and chinese gear kits off of amazon, and about $2.62 in PETG for the printed parts. All in I'm out $1,534 and another 72 man hours of labor.

Issue #4: Hotend PTFE alignment required an adjustment after 250 or so print hours. When it did go, it usually took a print with it as well as compounded issue #3 above. I tried to impose more force on the barrel of the heatbreak with M3 x 4mm SS cap screws, with did seam to help but not completely eliminate the issue. This was solved by replacing the heat sink and heat break with the E3D all metal parts kit along with the printed bracket noted above. Each kit ran $40, plus $1.80 in printed parts. All in I'm out $1,543 and another 36 man hours of labor.

Issue #5: Heated bed thermistor cable breaks. I get 2-4 of these a month, even with X and Y axis cable chains installed. I'm currently rolling out a 16AWG silicone wire modification on an attrition basis, with the first set going in this last Tuesday. This mod required a solder splice on the 2 ends. Each set of wires runs about $2.00. My projected cost for this mod is $72.00 and I expect it to consume 54 man hours over the coming year(s).

Issue #6: The filament runout sensor was unresponsive while under octoprint control. This was especially frustrating since I now had the MK3S+ extruder (R6 port, the first round was R4) on all of the 36 minis. 4.3.2 RC2 fixed this issue for me, and was rolled out to the farm prior to the 4.3.2 official release. The filament sensors now all perform as expected.

So, with all of the labor and mods to get these infernal machines performing at the same reliability rate as the MK3S, I had to spend $4,149 and invest over 200 man hours of labor to mod and troubleshoot. The lost time/materials in failed prints wasn't tracked but I'm sure it is not insignificant.

Bottom line: I spent almost 10% of a work-year (2080 on a 5/40) fiddling with these machines, which is more than I bargained for. That said, now that I have a list of required mods and a track record of GREAT performance after mod, I'll probably buy another 20 minis if I need to scale again.

Same problem.

Got it tuned in for PETG. Transferred months later to PLA and it chokes every time. Most frustrating and unreliable machine I've seen.

Have these issues too

I was excited to receive this printer after being referred to Prusa by a friend. I got it all put together last night and printed my first two prints without issue (the sample Prusa logo & one of my own). I started a 3rd print which was going to be a 10 hour print, so, I got it started and went to bed, only to get up in the morning and see it had only printed the first few layers. The nozzle was jammed. Fiddled with it for a couple hours this morning and can't figure out what the issue is. I am pretty frustrated. I should not need to be disassembling a brand new printer to troubleshoot it. I was under the impression Prusa was a no nonsense experience. I'll spend some more time on it this evening to see if I can figure out what's going on.

Jamming and clicking

I spent the last two days trying to clear something that kept clicking and jamming. I almost decided to disassemble the printer. It would load correctly and jam on the first layer. It was maddening. It seemed to be extruding normally, then click, click, click, and jam. It was maddening.

The filament was dry. The filament worked on another mini. I cleared the hotend with a 1.7mm tungsten rod. Then it would jam again. Click, click, click, and jam.

Then I tried a special purging filament. I loaded it. Let sit for 60 seconds, purged, let it sit for 60 seconds, and then unloaded it. Now, 5 prints have been successful. I was down 48 hours and it was this easy to fix.

--------------------

Chuck H

3D Printer Review Blog