not sure how to remove this blockage.

I have a jam somewhere that I'm not sure how to get out. I tried my luck at printing with a .25mm nozzle but wasn't having much success. I got to a point I couldn't insert the filament past a certain point when loading the filament and nothing was coming out so I swapped back to my trusty .4mm. However the blockage must be higher up from the nozzle because i'm still getting stuck when trying to load the filament and nothing is coming out. When opening the door I don't see any issues.

In the attached picture you can see right where the filament enters the tube. I sharpied a red mark on the filament where it is about to enter the top, then 5 cm above that is another red mark of where it stops just above the top. So from the point of entering the tube, it goes down another 5cm, but won't go any further.

I've tried taking filament and just pushing from the top down with the nozzle hot, but doesn't seem to budge. I've tried a cold pull but doesn't seem like the fresh filament gets to the point it can melt with anything as it just pulls back up easily.

Any ideas?

RE: not sure how to remove this blockage.

I have a jam somewhere that I'm not sure how to get out. I tried my luck at printing with a .25mm nozzle but wasn't having much success. I got to a point I couldn't insert the filament past a certain point when loading the filament and nothing was coming out so I swapped back to my trusty .4mm. However the blockage must be higher up from the nozzle because i'm still getting stuck when trying to load the filament and nothing is coming out. When opening the door I don't see any issues.

In the attached picture you can see right where the filament enters the tube. I sharpied a red mark on the filament where it is about to enter the top, then 5 cm above that is another red mark of where it stops just above the top. So from the point of entering the tube, it goes down another 5cm, but won't go any further.

I've tried taking filament and just pushing from the top down with the nozzle hot, but doesn't seem to budge. I've tried a cold pull but doesn't seem like the fresh filament gets to the point it can melt with anything as it just pulls back up easily.

Any ideas?

First try following these instruction: https://help.prusa3d.com/en/article/clogged-nozzle-hotend-mk3s-mk2-5s_2008

You can also unscrew the nozzle and try to push the filament through the hotend with a 1.5mm wire and clean the nozzle with a hot air gun.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: not sure how to remove this blockage.

There are surfaces inside the heat break that can block filament. You can remove the nozzle, and push filament upwards to carefully force the plug up out of the heat break and heat sink.

There is the third type of heat break jam that requires a full disassembly, warm soft filament wedges in the gap between the PTFE and heat break, making a large ring that can't move at all. These are pretty rare.

Yours sounds like the more common heat break step jam. The filament in a step jam looks like this photo: once that sharp step is formed, filament can no longer move downwards into the melt zone. But the stub can usually be pushed back up and out the top of the extruder when pushing up from the open nozzle orifice.

RE: not sure how to remove this blockage.

@tim-m30

I wholeheartedly agree with your post, the jam as you said may be caused by the space between the bowden tube and the heatbreak.

You may need to increase your nozzle temperature to ensure that the filament is fluid enough to not get stuck.

From the image that you posted there appears to be some residue on the Bondtech gears which probably caused some slippage, make certain that your extruder is not clicking when you print.

Stay safe and healthy, Phil

RE: not sure how to remove this blockage.

@tim-m30

I'm assuming it will need to be cooled down again before shoving filament up into it? I took the nozzle off, let it cool, and fed filament up from the bottom, but it only goes up about an inch then stops. How safe is it to use a paperclip or something more rigid? or is that not a good idea?

I also tried just heating up the nozzle hotter than normal to see if it would heat up more to melt things, but still couldn't feed filament down past a certain point.

RE: not sure how to remove this blockage.

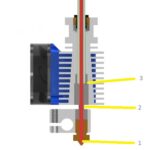

Folks have used Allen wrenches and copper rod (14 awg solid copper wire) to push with. And if the nozzle is out, then you can heat to 250c, open the idler door, and push down with a long object, and try melting out the obstruction. Pushing upwards you can damage the PTFE if there is a jam that far up ... here's a cut-away view of the hot end so you can see where obstructions can wedge in.

RE: not sure how to remove this blockage.

1 is where a nozzle plug is common

- use a cold pull to clear

2 is where the heat break can jam

- simply unload the filament, clip the stub, and reload filament

3 is the much less common PTFE jam area

- requires full disassembly of hot end

RE: not sure how to remove this blockage.

Also - there has been a couple cases of the PTFE grabbing the filament just above 3. It's unclear to me what is causing this, but a few people have had it happen. Probably related to printing in a hot environment - like an enclosure - but I don't have enough info on conditions, so just guessing.

When pushing upwards with the nozzle out, the heat break end is about a half inch up in there, and will block your effort unless you are centered. You need a mirror to see what you are doing, or unplug the printer and turn it on its side. Be sure to raise the x-axis as high as it'll go to give yourself room to work.

RE: not sure how to remove this blockage.

Thanks for all the feedback everyone!

I got the printer on it's side, nozzle removed, fed filament back up through the hole, and tried pushing back up to no avail. Nothing was budging.

I guess it's time to try and disassemble the hotend unless anyone else has any other ideas.

RE: not sure how to remove this blockage.

Update: Wife went to bed early so I'm taking this precious free time to take it apart.

Good news = Definite jam in the PTFE tube, was able to clear it out. I assume I can resume using it again? Guess if I have further issues I can replace.

Bad news = When I was slowly taking off the top motor part, a nut fell out, and I have no idea where it came from haha. Going through instructions trying to find where its home is 😛

RE: not sure how to remove this blockage.

Figured out where the nut came from. All back together and recalibrating. If I have any further issues with feeding I will replace the tube but it looked fine looking down it with light.

What I learned - If I have to manually shut down, I need to start it back up and turn on the fans to make sure heat doesn't creep up the tube and cause a jam.

Thanks everyone!

RE: not sure how to remove this blockage.

(...) If I have to manually shut down, I need to start it back up and turn on the fans to make sure heat doesn't creep up the tube and cause a jam.

There is other options. You don't have to turn it off and on again. Just go to "Preheat" -> "Cooldown" option (last). It will set target temperature of nozzle and bed to 0. And will keep fan turned on. I leave it like that until reaching below 70deg. But 99% of time I forget about it and it reaches ambient.