Heat break clogging - How did this happen? (And how can I avoid it?)

I have been printing for less than a month, and the printet started to jam (filament not coming out of the nozzle, extruder clicking,...). I changed the nozzle, and it did not correct the problem.

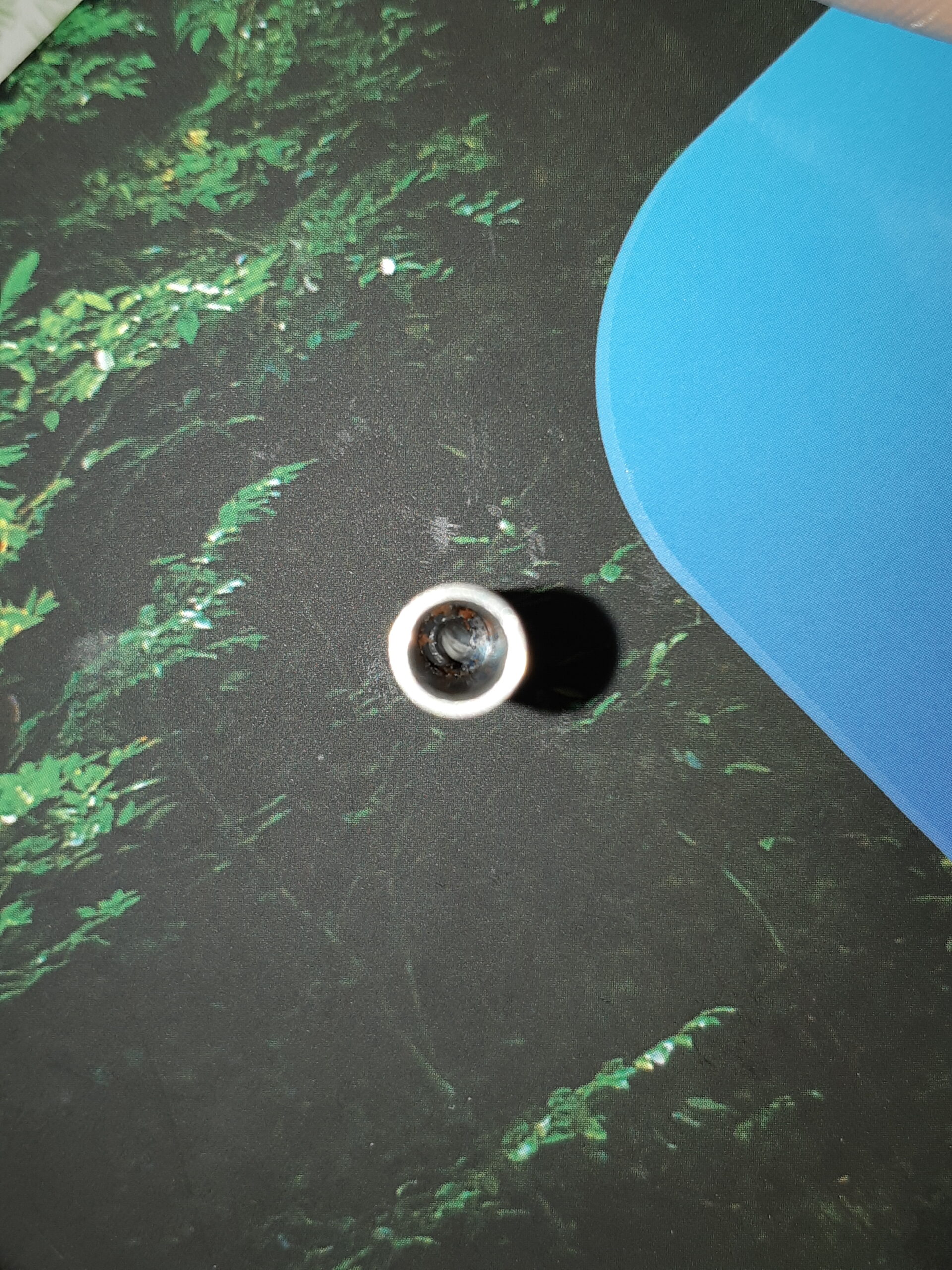

So when I removed the PTFE tube ( which is not clogged ) and looked down the hole, I noticed an odd accumulation of PLA and PETG.

I removed the heat break tube to make sure that it was the cause.

I would to know how this happened, how can I fix this, and how I can prevent this?

I have been printing PLA and PETG up till now. I have changed nozzles before without trouble. And I have replaced the PTFE tube due to accidental dammage to the previous one.

heatbreak

There are many videos on Youtube explaining this topic -I recommend this one.

In short, main reason for why that happens, is (poor) design of the original heatbreak. Usually clogs start to happen after switching between different types of filaments (different hotend temperatures). Clogs are also unavoidable if constantly printing with filaments which require high temperature (PETG, ASA,..).

Why that happens? Because PTFE tube starts to shrink at high(er) temperatures and so melted filament start to collect at the bottom inside heatbreak (as you can see on your photo).

To solve the problem, you can try to use Capricorn tube inside heatbreak (instead of PTFE). Capricorn tube is a bit more temperature resistant than PTFE. But it's quite expensive and doesn't really guarantee the success (if you also plan to print with ASA). Better long term solution (in my opinion) is, that you replace heatbreak -as shown on above video.

[Mini+] [MK3S+BEAR]

Capricorn fix

To solve the problem, you can try to use Capricorn tube inside heatbreak

It is so funny that this is the first time someone actually mentioned this solution.

I have an Ender3 V2 that has this in place and I have no problems whatsoever. I print mainly in PLA and I have tried TPU which uses the same hotend temp the PETG requires. On youtube it is called "CHEP hotend fix"

I am buying a Mini+ but It is still unclear how to solve this hotend issue.

BondTech/Triangle Lab heatbreak seems to be the best choice but some users who did it had problems because you need to make some gcode changes.

Something like:

M301 P13.54 I0.98 D46.58 ; Bondtech heatbreak M117 New PID loaded M73 P100 R0

You need to insert that gcode either in the slicer or print before each print, but the right info is unclear. Perhaps since you have it installed, you could please clarify what am I missing?

Thank you