RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@jeff-cogburn

Hello Jeff,

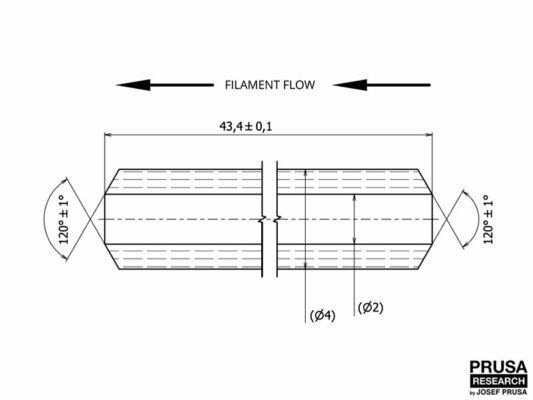

Here is what you can find into Prusa information: refer to the jpg file attached

Hope this could help

Rgds

J'essaye de faire, mesurer et partager...plus pratique que théorique, peu de blabla, des résultats… La preuve incombe à celui qui affirme….en faisant et mesurant

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

Thanks so much for the helpful posts. Can confirm issue still exists. My Mini ran great for 3 months then fell into this same situation. Was able to get it running again with adjustments to the tube in the hotend. Keeping the other suggestions on hand in case that doesn’t permanently fix the issue.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@andy-21

Hello,

Once this clogging issue araised, then you have to pay attention into disassemble and to clean everything. Please refer to page 4 of this topic, if not already read...

For this small piece of PTFE tube, inside the heatbreak, you need to insure it is a little bit "constrained" so it can not move at all up/down.

Also, extruder system (bowden) gear/teeth has to be cleaned on regular basis (brush/needle + air pressure)

There are some hardware solution to this: Triangle Lab or Bondtech...

If you can, check also real Temperature of extruder output....you may found lower than expected (around 5~7°C for me) so you may consider this on the slicing parameters.

Best regards

J'essaye de faire, mesurer et partager...plus pratique que théorique, peu de blabla, des résultats… La preuve incombe à celui qui affirme….en faisant et mesurant

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@marc-16

This worked for me mostly. I did the same measure and the temperature seems a bit off. What is rather frustrating though with this is that one print is perfect, then the next print it jams, etc.... This is our first prusa printer and so far had more trouble with it that any other printer (and we have 20 of them). But at least the increased temp seems to work for now.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

Hello,

I got a new Prusa Mini (see the Got My Original Prusa Mini Last Night post), and the test filaments worked great. The quality was awesome, and I uploaded by Benchy pictures, which looked very clean and good. I then switched to some generic PLA I had lying around and... well, it consistently would stop extruding after an hour or two. The filament would jam, and the filament loader would start carving away big gashes in the filament. "Unload Filament" was almost always useless in those tests, as it would spin and say "Unloading" without the filament moving. To unload the filament, I had to repeatedly unscrew the tube on the extruder part, and the end of the plastic would be visible but thicker (too thick to fit back into the tube). I'd cut this little bump with a scissors, press "unload" again, and then it would unload (still with gashes in the filament).

This happened repeatedly and was frustrating, so I bought some Hatchbox Black PLA on Amazon. And the quality of that PLA has been... terrible. Let's just say that. It has the same problem, consistently jamming in the extruder after about an hour or two of printing. The layers are much more "rippled" on the edges. The Prusament was very smooth, the Hatchbox is super textured on the sides and looks like the stereotypical 3D printed object. This was surprising considering how highly Hatchbox scores on Prusa Forums and on Amazon reviews. Despite my best efforts, I can't stop the Hatchbox or my other generic PLA from jamming after an hour or two of printing, mid print.

I've given up and ordered some Prusament on Amazon US, but I'd really like to get my other filaments working. Anyone have any ideas? I'm really new to all of this, and it's frustrating to order new (highly-rated) Filament that has the same problem as the previous stuff. My temps are 215/210C on Extruder. I tried setting to 195C but it didn't extrude almost at all.

I am having the same problem only printer a week, i have Creality printers and they are fine, so dont the issue yet, spending alot of time wasted trying to sort out, if anybody finds out let me know please

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

Had printer for a week and same problem, i have 8 other printers not Prusa and fine going have to spend alot of time sorting this i feel

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

My opinion about filament jamming/clogging on Mini (and I'm not the only one thinking that way)...

By assuming printer is built properly, the reason is either heatbreak and/or extruder. Some say "but it printed fine for about 3 weeks.." or "it prints fine with particular filament",... -but that tells nothing. The thing is, if printer has tendency to jam/clog, the same will, sooner or later, also happen with filament that works just fine right now -especially if we relative often change between filament types (where some require high nozzle temperatures).

This video explains why Mini's original heatbreak solution fails over the time (it's proven that PTFE tube shrinks inside heatbreak over the time -because of high temperatures). There are two solutions: often cleaning heatbreak (+replacing PTFE tube inside), or replacing original heatbreak with a better one (as shown in video). Once heatbreak is replaced, these trouble should be gone.

Extruder... in my opinion, once heatbreak is replaced, original Mini extruder should work fine in most cases (assuming idler screw is tighten properly). The thing is, if we often hear clicks from extruder (skipping extrusion), that means it's some jam inside heatbreak or nozzle. But as we already replaced heatbreak, chances for that to happen are quite small. But for "just in case", I also decided to replace original extruder with the one shown in this video.

Now, after I changed these two components, the only thing that can cause issues is either printer's physical adjustments (geometry, idler tension, etc.) or non-optimal settings in slicer.

Just sharing my opinion.

[Mini+] [MK3S+BEAR]