4.1.0-RC1 Firmware for Original Prusa MINI

Hi guys,

this is a testing release recommended to experienced users! There are major updates to the functionality, we would appreciate any feedback 😉

Summary

- Improved behavior after USB drive removal

- Marlin Card Reader replaced

- Printer acoustic signalization

- Filament load/unload procedure adjusted

- Preheat function improved

- Tune menu extended

- File browser improved

- Horizontal scrolling text

- Octoprint screen improved

- Watchdog dump feature

- Support for NTP servers

- Safety measures for filament load/unload

- Reworked temperature regulation

- Bug fixes

Detailed description

Improved behavior after USB drive removal

If the USB drive was accidentally removed or randomly disconnected during the print, the printer failed to continue. Now, the printer parks the print head in the rear right corner of the heatbed, enters the “Pause” state and awaits user input. The user should re-insert the USB driver, then press the “Resume” button. The printer then returns to the last G-code coordinate before the interruption and if the USB drive with the G-code is correctly recognized, the printer continues with the print. Otherwise, the print head is again parked in the rear right corner.

Disclaimer: Even though the printer is capable of resuming the print after the USB drive is disconnected, it is recommended to keep the drive plugged in throughout the entire print. Disconnecting the USB drive and rewriting or adjusting the printed file might lead to unpredictable results.

Marlin Card Reader replaced

The Marlin Card Reader implementation is directly connected to the accidental USB drive removal behavior. We have modified the Marlin Card Reader with our own code and implemented it in the MINI firmware. Its main feature was to treat USB flash drives as SD cards. However, in case of any error during the print (e.g. unintentional USB drive removal) it sometimes ended up with a critical error leading to a failed print, in rare cases even caused a Watchdog reset.

The new implementation uses a FatFs library, which is a generic FAT/exFAT filesystem module for small embedded systems and replaces the previous “Marlin Card Reader” entirely. The USB drive is now treated properly and most of the crash scenarios are also fixed in this update.

Printer acoustic signalization

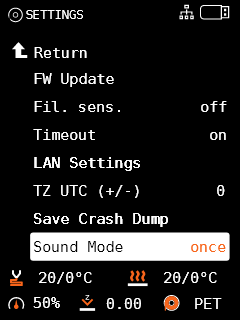

Firmware 4.1.0 brings 4 levels of the acoustic signalization - Loud, Once, Silent and Assist. The user is able to choose between each level in the printer's menu Settings > Sound Mode. You can also change the sound settings during the print in the Tune menu.

Level description:

- Loud - printer uses acoustic signalization to notify the users of a failure or if confirmation is needed

- Once - this level is similar to Loud, but all beeps are played only once

- Silent - most of the beeps are muted, the user is informed only in case of a serious error

- Assist - a mode for visually impaired users, the printer plays a different sound while scrolling through the menu and at the end of the menu.

Filament load/unload procedure adjusted

Previously, in order to load the filament, the printer needed to be fully preheated. As soon as the desired temperature was reached, the printer asked the user to load the filament through the extruder gears. From there, the filament was loaded all the way to the print head and extruded out of the nozzle. In case of any issue during the loading procedure, the user was unable to repeat the action or cancel it.

Filament load

Starting this release the overall logic driving the filament load is changed. The user is able to load the filament into the extruder gears (on the Z-axis) before the hotend is fully heated up and as soon as the temperature is reached, the printer automatically loads the filament all the way through the print head to the nozzle including the purge procedure at the very end.

After the filament loading procedure is finished, the printer will ask whether the color of the filament flowing out of the nozzle is correct. The following options are displayed:

- YES - filament loading procedure is considered finished, the printer returns to the previous menu

- NO - the filament is pushed again through the hotend again

- RETRY - the entire procedure returns to the beginning and awaits user confirmation about correctly loaded filament

Filament unload

Changes were also applied to the filament unload procedure, which is slightly more complicated than the loading. The printer now handles the filament unload procedure more carefully in order to achieve better results with almost no stringing and to avoid the creation of bumps near the tip of the filament strand. This improves the life expectancy of the PTFE tube inside the hotend and also the Bowden connecting the print head to the extruder. This new approach also avoids grinding of the filament while it passes through the extruder gears.

This method is also used during a color-change (M600). The previous method could sometimes cause jams and might have led to print failures. The print head is now always parked in the front of the printer to allow for easier access.

If you still experience stringing or grinding of filament, please let us know using the Issues section on the GitHub. Include information about your filament (type/brand etc.).

Preheat function improved

Several optimizations were made to the preheat function in order to shorten the overall time before the actual print is started. Now, regardless of the target print temperature as soon as the temperature of 170 °C is reached, the printer will allow for:

- the filament to be loaded to the print head

- the mesh bed leveling (MBL) to be performed

Also, the lower temperature in the print head prevents the filament from dripping down onto the heatbed. Once the MBL procedure finishes successfully, the printer proceeds to heat up the hotend to reach the target temperature and starts the print.

Preheat scenario (PLA used as an example):

- The user selects “Preheat” from the menu and then the material (PLA) they intend to load. The print head starts to preheat to target temperature (215 °C), but stops at 170 °C.

- As soon as the temperature of 170 °C is reached, the number on the screen starts to flash green, informing the user that the printer is ready to load the filament.

- For advanced users - the printer is also ready to perform the Mesh Bed Levelling, if this is specifically set in the G-code

Print scenario (PLA used as an example):

- The user selects “Print” from the menu, the material (PLA) is already loaded. The print head starts to heat up or cool down to reach the temperature of 170 °C. However, the printer knows (and displays) that the target temperature is 215 °C.

- The heatbed is heated up to the final temperature, in our case 60 °C

- As soon as the temperature of 170 °C in the print head is reached, the printer performs the MBL procedure.

- Once MBL is successfully finished, the printer continues to heat up the print head to the target temperature and starts the print.

Tune menu extended

Some parts of the printer’s menu are not accessible during the print for safety reasons. As a result, some important information might not be available to the user. From this release forward, the Tune menu is extended with “LAN settings”, “Version Info” and “Sound mode” submenus.

Thanks to this change, the IP address can be obtained even during the print and the user is able to monitor the progress using the Prusa Connect web interface. Similarly, the printer can be quickly muted for overnight prints.

File browser improvements

In case the G-codes were stored on the USB drive in various subdirectories, the user was able to list through the files and see the preview, but when the “Back” button was pressed, the printer incorrectly returned to the root directory. Now, the printer closes the preview, stays in the given subdirectory keeping the scroll and cursor position, thus enabling the user to continue previewing other G-code files in the same directory.

Also, the previous firmware releases sometimes experienced issues if the files were stored in multiple subdirectories. In this release, the total length limit of the path is raised to approximately 103 characters, which implies 103/(8+3) levels. The whole path is internally represented as DOS short file name 8.3 format.

Horizontal scrolling text

This function is now available for the MINI and well known from the MK3/MK3S printers enabling to read file names, which are longer than the width of the screen. If the cursor stays on the name the text will start to scroll to reveal the entire length.

Octoprint screen improved

Previously, when a remote print over OctoPrint was started, the printer locked the screen and displayed an “Octoprint” dialog. There were only two options available, open the “Tune” menu in case of adjustments needed during the print or reset (reboot) the printer using the hardware button if the print was failing.

However, not every failing print must be addressed by rebooting the printer, sometimes the print can be saved and for this reason in this release, this functionality is further improved with new options next to the “Tune” menu:

- Tune - standard adjustments to the running print

- Pause - a command is sent to the Octoprint server to pause the print

- Disconnect - a command is sent to the Octoprint server to disconnect from the printer. This also cancels the running print.

We would appreciate any feedback regarding the Octoprint integration, please let us know using the GitHub or forum.

Watchdog dump feature

This feature is an extension of the “Crash Dump feature” introduced in the firmware 4.0.3. Starting this release, the data is saved and included in the crash log even if “Watchdog reset” scenario occurs.

The path to retrieve the crash log remains the same Settings > Save Crash Dump. Note that the USB drive must be connected to the printer in order to save (export) the dump file.

Support for the NTP servers

Starting this release the printer is able to get the actual time using the NTP servers. This feature requires an active connection to the internet and brings a great addition to the running print.

An offline printer reads the duration of the print from the G-code and displays the remaining time on the screen. However, when the printer is online and acquires the actual time, it adds the time from the G-code needed to complete the print and on the screen displays the estimated time when the print will be finished.

Note that the NTP servers aren't able to retrieve the time zone your printer is in. In order to see the correct time, please head to the Settings > TZ UTC (+/-) and set the number of hours, which will be either added or subtracted from the NTP server time.

For example, our offices in Prague are UTC+2h, therefore the time zone settings have to be adjusted by +2 hours.

Safety measures for filament load/unload

The MINI remembers information about successfully loaded filament and its type. This release of the firmware adds several safety measures based on knowing this information. Depending on whether the filament is loaded to or unloaded from the printer, some actions are unavailable (greyed out) in order to protect it.

- Change Filament - in case the filament is not loaded, this action is disabled

- Purge Filament - only available, when the filament is loaded

- Load Filament - in case the filament is loaded, this action is disabled

- Unload Filament - available at all times, the printer automatically heats up

Note to the “Unload Filament” action, which is available at all times to cover scenarios even the failures (e.g. filament not unloaded properly). It enables the user to remove the filament in any situation, thus it is considered as a safe option.

Note to the “Filament sensor”, which is used during these actions. If the sensor is connected and activated it won’t allow for continuing the filament load from the Extruder to the Print head if no filament is detected passing through the sensor.

Reworked temperature regulation

The new temperature regulation algorithm is based on the long term observation of the printer behavior. It incorporates new physical parameters such as heat transport delay, the effect of the surrounding temperature and the thermal capacity of the heating system. The aim of these adjustments is to minimize the overshoots caused by the system inertia and transport delay, achieve the target temperature faster and enable more precise regulation in the area of the stabilized temperature.

The adjustments include:

- Fixes and improvements to the Marlin PID regulator (I parameter limitation, D parameter computation)

- Manual tuning of the defaults PID constants - lower P and I to increase the stability

- Increase of the D smoothing factor

- Implementation of the feed-forward regulator based on the system model

- cooling loses by radiation, passive convection and print fan-forced convection

- the thermal capacity of the system (parameter Deg_per_seconds)

- transport delay of the sensor (thermistor) of the heating system (parameter Transport_delay_seconds)

- Rewriting and reenabling the Marlin PID_EXTRUSION_SCALING feature (regulating term based on the cooling effect caused by the extruded material).

More details can be found in this GitHub pull request.

Warning for the users: in case you observe any significant drops of the stabilized temperature (larger than ± 5 °C). Please report it and include the G-code.

Bug fixes

- The print fan continued cooling even when the print was finished. This is now fixed.

- Large memory requirements of the file browser are now fixed and the overall demand for memory lowered over ten times. Previously the issue was with:

- Setting a limit to simultaneously ordered objects to 64

- Dynamically allocating about 8 KB of the memory

- If more than 64 objects were present, they didn’t display at all

- Fixed Draw line feature, which was displaying some lines 1 pixel shorter.

- If the print is paused and then canceled, the printer now correctly cancels the heating and stops the print fan.

- The inability to stop the print while the printer was heating up is now fixed.

Supported printer:

- Original Prusa MINI

Download link:

github.com/prusa3d/Prusa-Firmware-Buddy/releases/tag/v4.1.0-RC1

How to flash the firmware on MINI:

- Copy the firmware file (.bbf) onto the USB drive with FAT32 formatting

- Insert the flash drive in the MINI's USB port

- Turn the printer ON (or reset it)

- A new screen will appear

- Confirm you want to flash the firmware

- Wait till the firmware is flashed and printer fully boots into the home screen

Please report any bug here:

github.com/prusa3d/Prusa-Firmware-Buddy/issues

As always, we wish you happy printing and look forward to your feedback!

RE: 4.1.0-RC1 Firmware for Original Prusa MINI

Linking other thread as there were already some ongoing discussions/observations

RE: 4.1.0-RC1 Firmware for Original Prusa MINI

4.1.0 has been released

Summary

- Improved behavior after USB drive removal

- Marlin Card Reader replaced

- Printer acoustic signalization

- Support for NTP servers

- Filament load/unload procedure adjusted

- Preheat function improved

- Tune menu extended

- File browser improved

- Horizontal scrolling text function added

- Octoprint screen further improved

- OctoPrint vs filament change

- Watchdog dump feature

- Safety measures for filament load/unload

- Reworked temperature regulation

- Faster print head heat-up process

- Correct remaining time estimation for non-default speeds

- Short G-codes not printed completely

- Splashscreen fixed

- Bug fixes

from https://github.com/prusa3d/Prusa-Firmware-Buddy/releases/tag/v4.1.0

RE: 4.1.0-RC1 Firmware for Original Prusa MINI

New stable firmware 4.1.0 is out, more info here https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/4-1-0-firmware-for-original-prusa-mini-2/

RE: 4.1.0-RC1 Firmware for Original Prusa MINI

No change to the "beep" from the RC.. It was such an obvious issue, I am surprised.. I can't imagine anyone likes the new 'volume' functionality.. There isn't a mode now that I can use as even "Silent" lets out a loud beed during loading.

Hang on. That might not be sure.. Printed some things this morning and don't remember a beep, so perhaps they have fixed it such that 'silent' is actually 'silent'.. But its still horrible functionality as I want 'beeps' but they are currently really loud and obnoxious.

Lets hope for changes in 4.2

RE: 4.1.0-RC1 Firmware for Original Prusa MINI

Any idea when the printer farm software may be coming out?

RE: 4.1.0-RC1 Firmware for Original Prusa MINI

No change to the "beep" from the RC.. It was such an obvious issue, I am surprised.. I can't imagine anyone likes the new 'volume' functionality.. There isn't a mode now that I can use as even "Silent" lets out a loud beed during loading.

Hang on. That might not be sure.. Printed some things this morning and don't remember a beep, so perhaps they have fixed it such that 'silent' is actually 'silent'.. But its still horrible functionality as I want 'beeps' but they are currently really loud and obnoxious.

Lets hope for changes in 4.2

I agree. I've just updated the firmware on mine and absolutely hate the new sound options! It's either super loud and annoying or dead silent. Can we get back the previous subtle "beep" as an option? It was fine! I'm flashing the old firmware again right now because I can't stand it, sorry Prusa.

RE: 4.1.0-RC1 Firmware for Original Prusa MINI

I guess they need to redefine silent mode. LOL silent means silent just like it was before. I hate those beeps during filament change too. Very annoying indeed.

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0