Re: Target humidity?

My higher end desiccants suggest 10 hours at 200f ... with a 3 hour minimum. I push it to 225f at the risk of breaking down the lattice (overpressure in small channels).

The suggestion that 350f is needed to dry the material suggests another mechanism beyond adsorption is in play, something chemical or even true absorption. After all, pure water boils at 212f - and then only needs time to migrate out of the open lattice.

But hey - I am only a home consumer of this stuff. In industrial applications, e.g., drying uranium, different strategies on temps might be appropriate.

Re: Target humidity?

Adsorption is an exothermic process, and different adsorbents release different amounts of energy as they adsorb moisture. See, e.g. "heat of adsorption".

You can directly observe this by placing some dried dessicant directly in water (note: if you do this with silica gel, it will likely cause the beads to break apart). The water+dessicant will get noticeably warm. And molecular sieves get significantly warmer than silica gel, because they have a higher heat of adsorption.

To dry the dessicant, you have to reverse the process. So you don't only need to boil off the adsorbed water, you also need to "add back" the energy that it gave off from adsorption. Since molecular sieves have a higher heat of adsorption, they require higher temperatures to regenerate.

Re: Target humidity?

I think your're wrong in your assumptions, but rather than dig out my chemistry books ... I agree we disagree.

Re: Target humidity?

Haha. I'd be curious to know what it is you disagree with. I'm certainly no expert - just another random guy at home who reads stuff on the internet, and occasionally tries stuff for himself :).

Re: Target humidity?

I found this an interesting read on regeneration of molecular sieves http://gasprocessingnews.com/features/201802/proper-regeneration-of-molecular-sieves-in-tsa-processes%E2%80%94part-1.aspx

Re: Target humidity?

I found this an interesting read on regeneration of molecular sieves http://gasprocessingnews.com/features/201802/proper-regeneration-of-molecular-sieves-in-tsa-processes%E2%80%94part-1.aspx

Yep - industrial use of zeolite drying hydrocarbons at 200c and higher ... not exactly what is needed for keeping filament dry ... lol.

Re: Target humidity?

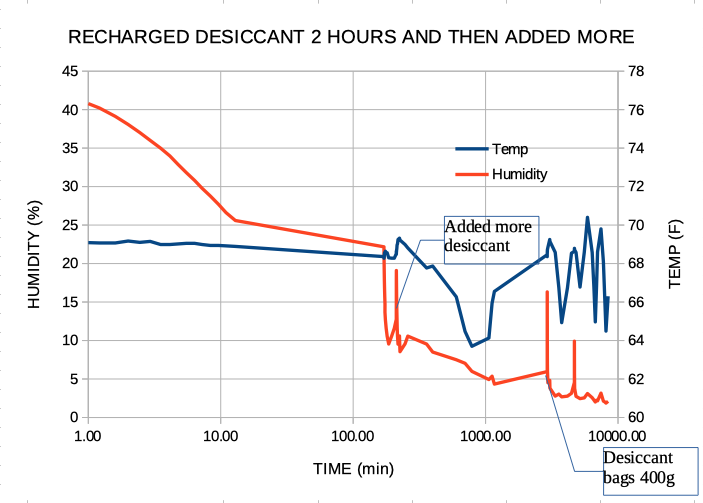

Here's some plots you might find interesting. Theses were made using a Seeed Studio https://www.seeedstudio.com/Grove-Temperature-Humidity-Sensor-SHT31-p-2655.html that claims +/- %2 relative humidity.

Note the time scale is exponential.

I have a 46 quart container with good seals, with 5 rolls of PLA, 4 of PETG and one BridgeNylon.

The first 100 minutes shows the typical effect I had after taking a reel out and using it in 40% humidity. It took almost 2 hours for the humidity to get back down to the %20 range it started at when I took the reel out. The sensor responds in seconds (about 9) so your seeing the actual change. Also realize this is relative humidity so temperature changes effect it. At that point I only had about 20 of the small desiccant packs that came with the filament and other various items and had just dried them for 2 hours.

As the graph shows I added more desiccant, first about 30g of ~30 year old indicating silica balls that I dried out from the floor of the garage. They quickly dropped the humid down.

I then purchased about 400g of desiccant and dropped that in. It took a while to suck the moisture out of the reels but eventually got the humidity below %3.

My guesses with my experiences would be:

PLA worked fine at 40% relative, 70F

PETG worked better below %20

BridgeNylon worked better below %10

Also leaving the box open even for a few seconds takes a long time to suck the moisture out of the nylon which acts like a desiccant.

Re: Target humidity?

Here's some plots you might find interesting.

[snip]

Also leaving the box open even for a few seconds takes a long time to suck the moisture out of the nylon which acts like a desiccant.

Interesting indeed - and good instrumentation and data logging. But your sensor is only seeing moisture (%RH) in the air around it, and your'e are left with no clue of the actual nylon moisture content. Add the fact that nylon is slow to absorb water (tc around 10-20 days in damp air) ... the data suggests RH inside your box is probably low enough to assist in drying saturated nylon left in the container for several weeks.

An interesting test you could do with your setup in to immerse a spool of 1.75 mm nylon filament in 100c hot water for at least 24 hours, drain it, or transfer it to a new spool using a towel to clear any loose water off the filament, and then stick the saturated spool in your dryer (with fresh desiccant) and monitor RH over a few weeks.

If you start with a new spool of filament packed in a sealed bag with desiccant - weight it before placing in water - and again when removed, you can verify moisture content, and use those numbers to confirm efficacy of your dehydration box and have a good idea how long it takes to dry your filament to some predetermined level.