Printing problems with 0.6mm Nozzel

Hi guys, lately I have occasionally a problem while printing. The print has been running for some time (in this particular case about 2 hours) and then suddenly a large amount of filament is extruded, see picture. This causes the print to be pushed off the platform and everything is screwed up. I had the thought that it might be due to the fact that a high pressure builds up in the nozzle and this then spontaneously deflates after a while and this leads to the bubble. Do any of you have an idea where it could be coming from and what I could do about it?

I use a 0.6 nozzel with the 0.6mm profile from PrusaSlicer with Prusa PLA (I tested my filament and printed a cube and a stringing test and everything was ok).

I also did a cold pull and everything seems to be fine here as well.

RE: Printing problems with 0.6mm Nozzel

Is it possible that when you changed the nozzle, you accidentally tightened the nozzle against the heatblock instead of the end of the heatbreak

Check on top of the heatblock, for molten filament...

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Printing problems with 0.6mm Nozzel

@joantabb

Thank you joantabb for the answer.

I dismantled the Nozzel again this morning and checked everything. I could clearly see that the Nozzel was in contact with the intermediate piece and that there was no gap between them.

I will do another test today with an extrusion multiplier of 0.96.

RE: Printing problems with 0.6mm Nozzel

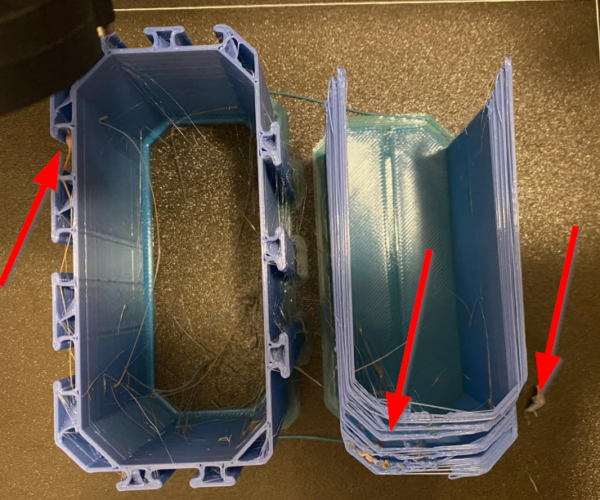

So I finished my test today.... and as you can see from the picture it was not successful.

I started the print with an extrusion multiplier of 0.96 and after about 2cm of printing I reduced it even further to 0.9 during printing. As you can see in the picture there are spots all over the part where a large amount of filament was ejected, the clumps that form are also brown in colour which indicates that the filament is overheating.

During the last 10 minutes of printing, the right part came off the platform and this caused the offset top... and I stopped the printing!

Honestly, I am at a loss as to what the problem could be. I hope someone can help me...

RE: Printing problems with 0.6mm Nozzel

@achiles

So did you fix the problem of not having a gap between the nozzle and the heating block?

RE: Printing problems with 0.6mm Nozzel

@jerry

I'm sorry, I think I did a bad job of explaining it properly.

The small gap 1 is and always has been there.

and there is no gap 2 inside (I played it safe and rebuilt the Nozzel and looked inside before the second test).

RE: Printing problems with 0.6mm Nozzel

Hey, here's another update.

Yesterday I disassembled the entire hotend, cleaned it and reassembled it. I found a significant amount of fillament on the heat block (between the heat block and the heat sink) and removed it. I'm not sure where exactly the filament came from, but there was also significant play between the heat block and the heat sink, though I don't really know how melted plastic would come out of that.

Anyway, I cleaned and reassembled everything and have now printed for about 10 hours with the 0.6 Nozzel and have had no problems and the parts look great.