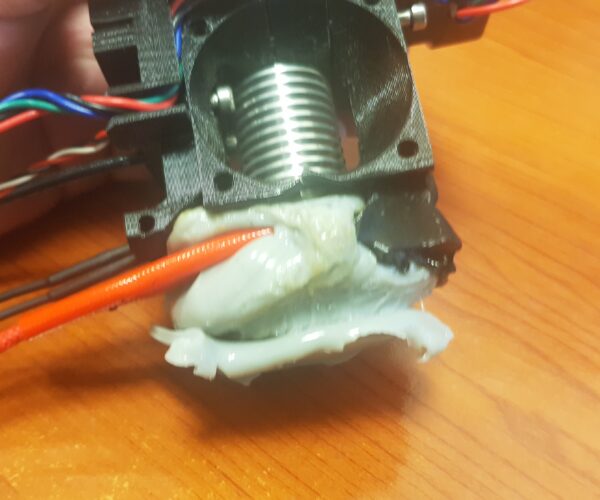

Need help on how to deal with this disaster!

Good day. To you not for me as you will see =)

Printed with ABS all was fine for many hours , then I left for the print unattended and it got loose from the bed.

Got the head off and now I sit here thinking how to deal with this. I have heat gun...

Any ideas? advice ? is it even possible to remove this blob peace by peace using a heat gun ?

RE: Need help on how to deal with this disaster!

Heat gun and patience. Take great care freeing the wires, they are fragile and expensive. But from the looks of it: the contact with the extruder plastic and the chance the blob welded to it, and damage already done, a new hot end might be in your future. Recover what you can from the blob for spares.

In the sailing trade, riggers use hot knives. It just came to me that one might be a good tool to have for these events.

RE: Need help on how to deal with this disaster!

Good day. To you not for me as you will see =)

Printed with ABS all was fine for many hours , then I left for the print unattended and it got loose from the bed.Got the head off and now I sit here thinking how to deal with this. I have heat gun...

Any ideas? advice ? is it even possible to remove this blob peace by peace using a heat gun ?

You could first try heating the nozzle to 250 degrees C. and let the heat work for about 1 hour. Afterwards try to remove the coarsest parts with a pair of pliers and wooden sticks. A heat gun supports the operation.

Some extruder parts you will have to replace.

Good luck!

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Need help on how to deal with this disaster!

You have one of the less severe of these, sometimes called the Blob Of Doom.

I had one which appears to be slightly smaller than the one you have, and it came off in one piece without damaging anything by simply heating the nozzle (IIRC it was 255) and letting it sit for 1/2 hour or so. Heat and gravity did their thing and it was able to be gently pulled loose with no other damage.

Mine was PLA, and yours is ABS, which may take more heat, time, and careful removal. I would echo concern to avoid damaging the thermistor wires.

RE: Need help on how to deal with this disaster!

One other point: if you do use the machine to heat itself: when you are probing around with pliers and sticks to remove gunk, remember that the 24v heater wires are active and not insulated - a short can and will damage the Einsy board.

RE: Need help on how to deal with this disaster!

HI,

I've just tried out a plastic repellent paint from Slice Engineering coating the heat block as well as the nozzle. It does work good as the plastic almost falls off by itself. They advertise it as a PTFE paint and comes with a brush in a small bottle. I almost had a blob, but after a minor heat up, 190ª, it just all came off.

Stay safe and healthy, Phil

RE: Need help on how to deal with this disaster!

[...] They advertise it as a PTFE paint and comes with a brush in a small bottle. I almost had a blob, but after a minor heat up, 190ª, it just all came off.

Just be aware that PTFE (Teflon) can break down at temps over 250C. It can release toxins at higher temps. It can have particularly bad effects on birds. This is why all metal hotends without PTFE tubing are needed for high temperature filaments.

RE: Need help on how to deal with this disaster!

And some data shows that the neurology of cats are in that affected group too. Nasty stuff.

RE: Need help on how to deal with this disaster!

Noted, anything that we do with our printers carry different dangers to ourselves and our pets as well. This why we try to follow the recommendations that come with the use of our machines.

Okay, so we are printing with a printer that puts off toxic fumes but we shouldn't use a product that may be harmful to pets. Most of the plastics we print with are toxic and that is why the printer should be in a well-ventilated area.The amount of paint I have used on the nozzles is quite insignificant given that I have treated ten nozzles and the bottle, 3cc, is still full. The PTFE tube in the extruder is made of this harmful and toxic material and is at the end of the heat break, this probably gives off more toxicity than a minimally dried on paint. The instructions for use mention that the product must be dried prior to using it. The compounds that we use to mate our heatbreaks to the heat block are toxic as well, we use them to distribute the heat and keep the parts from siezing together.

My previous printer had instead of replaceable nozzles they came with a head assembly which had teflon coated nozzles to prevent the plastic from sticking to the plastic. The amount of product on those nozzles was notably higher than the miniscule amount that one uses on these nozzles. Any product we use with our 3d printer gives off some amount of toxicity harmful to organic life. The point is that any product must be utilized judiciously and instructions for the use of said product should be followed. Driving a car in the middle of a major city we are exposed to toxins that the fossil burning vehicles emit, these are also nasty on organic life, but we still drive in major cities exposing ourselves to toxic fumes.

Now, my point is: having a 3d printer in a home environment carries responsabilities for the co-habitants within that home. Following all instructions for the build and use of said printer is a must to ensure that we minimally effect them and our environment.

Stay safe and healthy, Phil

RE: Need help on how to deal with this disaster!

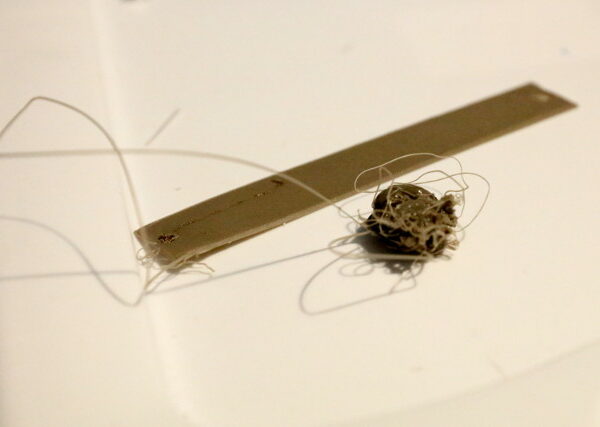

Huge thank you to all the replays and suggestions ! Helped me allot! Can not be more grateful! All came off with no problem While doing as @jsw and @karl-herbert advised. Heated the extruder to 260C and heated it for about 30 minutes. The blob came off with some slow pulling, not to damage anything, and patience. Then I removed the wires using heated plastic cutting "knife". All came out nice and with no damage.

Sure I will be printing new extruder cover and holder with airduct. But all in all Everything is fine and in working order. May consider using Plastic repelent paint @pcweber advised if I will get my hand on it.

Anyhow Thank you again for all the help !

RE: Need help on how to deal with this disaster!

@pcweber

Well - you might be printing with toxic filaments, but I am not. I use PLA (shown to be inert in mammals) and PETG (also shown to be harmless unless injected into veins or like water, ingested in sufficient quantity to cause cancer).

ABS, ASA, do have hazards printing byproducts, so I avoid them. Teflon is at a different - significantly higher - level of risk. And ignoring that risk isn't only up to you: do you have family, friends, or even neighbors that you are harming?

RE: Need help on how to deal with this disaster!

[...] Okay, so we are printing with a printer that puts off toxic fumes but we shouldn't use a product that may be harmful to pets. Most of the plastics we print with are toxic and that is why the printer should be in a well-ventilated area.

Just to be clear: The emission of ultra-fine particles (UFP) by all 3D printed filaments, the emission of volatile carcinogenic emissions (e.g. styrene emissions from ABS) and the emission of neurotoxins by overheating PTFE are each very different topics. The concern with PTFE is not the same as with typical 3D printing filaments.

The amount of paint I have used on the nozzles is quite insignificant given that I have treated ten nozzles and the bottle, 3cc, is still full. The PTFE tube in the extruder is made of this harmful and toxic material and is at the end of the heat break, this probably gives off more toxicity than a minimally dried on paint.

The use of PTFE-lined heatbreaks is why many cheaper printers are limited to 240C maximum printing temperatures. The Prusa Mk3 printers use an all-metal heatbreak that only has a PTFE guide at the top of the heatsink where temps will rarely reach 50C. Breakdown of the PTFE tubing in the E3D V6 all-metal heatbreak used on the Prusa Mk3 is not a concern at normal printing temperatures. Use of PTFE-lined heatbreaks is a common problem encountered by unwary users of other printers who modify their firmware to print at higher temperatures without any awareness of the issues. If nothing else, the tube degrades and causes blockages.

The instructions for use mention that the product must be dried prior to using it. The compounds that we use to mate our heatbreaks to the heat block are toxic as well, we use them to distribute the heat and keep the parts from siezing together.

I would hope you're not using products that emit neurotoxins regularly, particularly if you have birds or other pets, or even just family members.

[...] Now, my point is: having a 3d printer in a home environment carries responsabilities for the co-habitants within that home. Following all instructions for the build and use of said printer is a must to ensure that we minimally effect them and our environment.

I would certainly include consideration for the fact that a product I am using can emit neurotoxins at temps as low as 280C/536F (within the range of some PETG filaments and below the temperature of 285C recommended by Prusa and E3D for changing nozzles) among those responsibilities. http://www.peteducation.com/article.cfm?cls=15&cat=18&articleid=287 4" target="true">Teflon toxicity is a well-known problem among bird enthusiasts, but many may not associate this with PTFE as used in 3Dprinters. You seem comfortable subjecting the human members of your household to toxins, but parrots and other birds are far more susceptible to far smaller amounts of exposure over time. From that link: "Mild exposures may result in difficulty breathing, wheezing, incoordination, weakness, depression, anxious behavior, or seizures."

The 3D printing industry as a whole is doing a poor job of identifying safety concerns, from potential fire hazards to harmful emissions. This is yet another example. I'm much more comfortable using a coated nozzle and heat block than adding PTFE to the hottest parts of my printer.

https://www.fabbaloo.com/blog/2020/3/18/is-your-3d-printer-killing-you-slowl y" target="true">More here.

RE: Need help on how to deal with this disaster!

It seems the forum software is mangling links today. For those interested, cut & paste:

Article on PTFE effects on birds: https://web.archive.org/web/20081009054607/http://www.peteducation.com/article.cfm?cls=15&cat=18&articleid=2874

General article on PTFE and 3D printing: https://www.fabbaloo.com/blog/2020/3/18/is-your-3d-printer-killing-you-slowly

There is a lot of debate about exactly which temperatures cause PTFE to break down, and damaged PTFE (e.g. scraped around nozzles) seems to be an issue at lower temps.

RE: Need help on how to deal with this disaster!

@pcweber

Lol - I missed the bit about toxicity of thermal compounds. I for one do not make nor use beryllium dioxide paste any more, honest. Alumina is NOT toxic [the common white thermal paste]. Silver [the common silver thermal paste], while mildly toxic, isn't horrible, and it is not giving off fumes even at 250c [tooth fillings use a silver amalgam also containing tin, copper, etc.].

While I agree painting the nozzle is probably not going to kill you - most of the product is likely binders and the actual Teflon content is low - different Telfon mixes are radically different in toxicity. Some are quite harmful when cooked at even low temperatures well below the common 250c everyone claims.

Pyrolysis of PTFE is detectable at 200 °C (392 °F), and it evolves several fluorocarbon gases and a sublimate. An animal study conducted in 1955 concluded that it is unlikely that these products would be generated in amounts significant to health at temperatures below 250 °C (482 °F).

RE: Need help on how to deal with this disaster!

Hi all,

I really wasn't comfortable with the responses here about this paint. I researched the SDS Safett Data Sheets on this product and found no correlation to all of the negative responses here. It even made me worried that I may have made a terrible choice by using this on my nozzles. A really positive note is that I have identified an active carbon filter that I'll be building along with placing a sensor within the enclosure and at the escape from the filter to the air surrouding my printer, thank you for opening my eyes to make my setup safer. I do have more information about the plastic repellent paint though.

Since the data sheet didn't correlate with what you all were responding to my earlier remarks I reached out to the manufacturer to see if they could enlighten me, clearing up this discrepancy. Seriously I couldn't fathom a group of young engineers selling a product that wasn't validated as to its safety prior to putting that product on the market. I reached out to the company and they provided me with a copy of their safety study comparing their product with many of the other components that we use with the FFF process. My surprise was the low levels the paint has as compared to even PLA, not to mention other printing filaments that we use.

Don't take my word here, I am posting their document to this post.

PS.: BTW I am going remix this: https://www.thingiverse.com/thing:2394452. I want to ad a CSS811 on the inside and outside of my enclosure and use a silent Noctua fan.

Stay safe and healthy, Phil

RE: Need help on how to deal with this disaster!

Thanks Phil. I was holding off using this due to such concerns.

RE: Need help on how to deal with this disaster!

Not to be contrarian, but being contrarian: I'll restate I doubt painting the nozzle is going to kill you, or your pets. A square foot of PTFE coating on a cooking pan versus a square inch on a nozzle is huge.

But - reading their study (thank you for posting)... Hmm, so they precured the paint at 204c for an HOUR before testing, claiming this is needed to remove the water-based carrier. Okay. How many of us dry our dishes at 204c? We already know PTFE begins outgassing at less that 200c - but let's give them a pass - most studies are done at 450c and higher.

Then, it also seems they only tested the PTFE oxidation byproducts rather than the other deadly stuff it gives up. Look up octofluoroisobutylene, a byproduct of overheating PTFE. But OSHA doesn't require testing for it, just like they don't require testing for Freon (chloroflouorcarbon) gas because the private sector has 'proven' it isn't dangerous.

Back to the bottom line: this is probably the same coating E3D (and others) apply to their coated nozzles and heater blocks to reduce sticking.