Fitting parts together

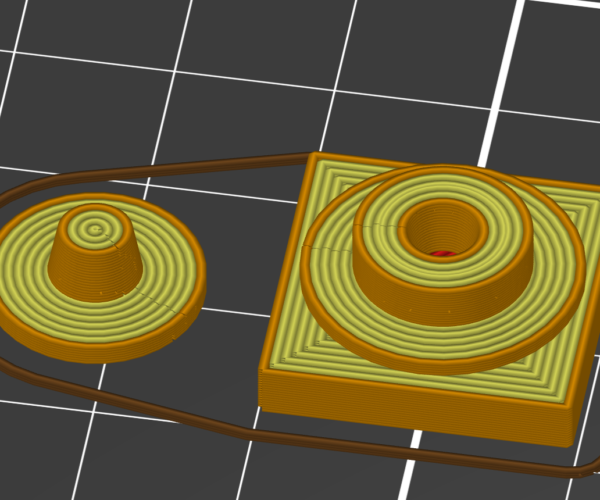

Using the standard .4 nozzle I was able to make two parts that would push fit (actually hammer fit). The male is exactly the same size as the female part.

After changing to a 0.6 nozzle the male part is larger than the female. Im wonder what setting I might be able to change, I have tried the extrusion width. (that is also a different issue which I might post later). As a last resort I made the male part smaller in the slicer but I would prefer not have to play with that.

Attached are the STL and 3mf files if you are interested.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Fitting parts together

It's been my experience that PrusaSlicer over-extrudes more with higher layer heights. Try just bumping your extrusion multiplier back 5-10% as a quick test. I am able to get threaded parts to work with a 1.0mm nozzle using 0.48mm layer heights with a 0.2mm tolerance without resizing parts.

RE: Fitting parts together

Based on a the Prusa test cube (and your helpful notes- thanks) I have set my Extrusion width to 1.08 - this gives perfect cube sizes. For my insert test I bumped it back to 1.05 and 1 and this didn't seem to make much difference.

Now I dont know if this is related but printing a part with the Extrusion width at 1.08 the top surface was very rough especially where straight perimeters meet circular inner perimeters.

Other items of note are the default extrusion width of .65mm which is less that your recommendations of 120%

Layer heights are 0.2mm

Maybe I should recalibrate my Z height but I thought it was pretty good.?

Also to make the insertion easier you might notice the uploaded parts had tapered meeting parts.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Fitting parts together

Try your basic settings with the extrusion multiplier (in filament settings) bumped back 5%. This is separate from extrusion width, mind.

RE: Fitting parts together

Ah my error I was meaning I changed the multiplier. It was 1.08 and dialed it back to 1.05 and 1.0.

The extrusion width is 0.65mm.

sorry for the confusion

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Fitting parts together

Just to confirm reducing the extrusion multiplier this doesn't seem to help.

Is anyone able to test the project file with a 0.6 nozzle? - is only takes about 10 minutes.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Fitting parts together

And, with small tapers, be sure you enable DETECT THIN WALLS or the taper may not taper ... 😮

RE: Fitting parts together

Thanks

After setting the default values the parts seems to be fitting ok. Maybe I had a bum setting somewhere.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Fitting parts together

Thanks

After setting the default values the parts seems to be fitting ok. Maybe I had a bum setting somewhere.

I've had PrusaSlicer set some weird extrusion widths when swapping nozzles. Always worth reviewing what it's up to. Glad you've got it sorted now.

Are you getting a push fit with no tolerance added? I normally add that 0.2mm for kids, but I've also noticed that Fusion 360 threads don't need anything added. Parts screw together nicely, even using a 1.0mm nozzle at 0.48mm layer heights. Other than tweaking the extrusion rate a bit, I'm pleased with how little I have to worry about in my Fusion 360 designs.