First-person report on first use of Prusament PC Blend

As I mentioned in another thread, after countless prints, the fan shroud on the MK3 has started to droop. Not enough to interfere with printing, but enough to be noticed when inspecting and cleaning the nozzle area.

After I finish the current project I'm working on (model railroad buildings) this week, I plan to take the machine down long enough for some modifications, mainly to the MMU2S such as an on-off switch and bowden tube fittings, so I figure it's a good time to replace the fan shroud as well.

I already have a spare shroud, as well as other extruder parts in my 'crash kit', but I read about the PC blend and figured it would have better heat resistance than the black ABS I used for the spare extruder parts, so I figured that's as good of an excuse as any to try it out. I ordered a spool from Prusa and it hit the front porch here in the States less than a week from placing the order.

It comes complete with a fresh Kores glue stick, as there are admonitions to use a release agent, since the PC blend sticks very firmly to the build plate.

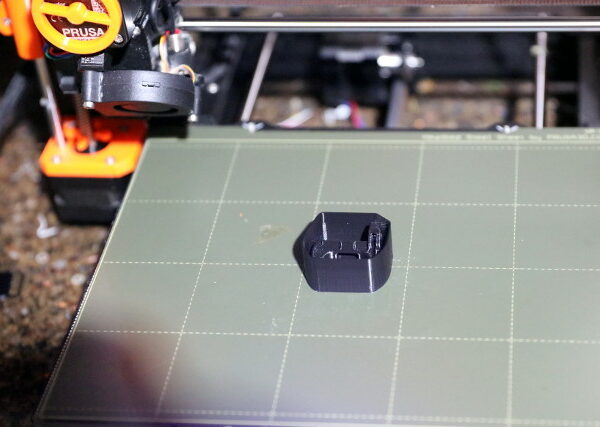

As instructed, I 'buttered' the center of the build plate with a layer of the glue stick. As an aside, you may notice some damage on the build plate in the photos. For these first prints with PC blend, I used the surface that I had previously ruined when becoming impatient removing a print with a large footprint, resulting in a few patches of the coating coming off with the print. The center is still good, more than enough for the shrouds.

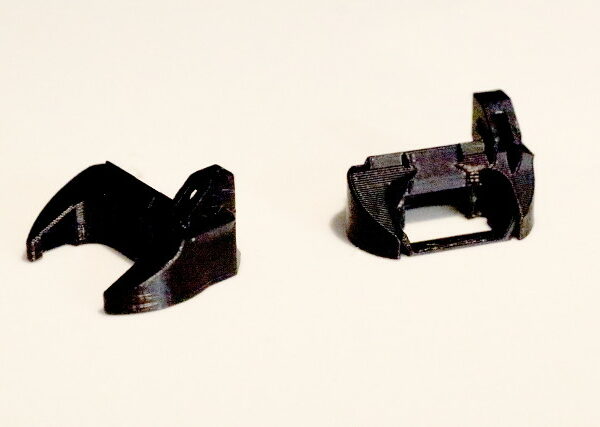

I printed both the stock Prusa fan shroud, and a remixed one which has been discussed here. I sliced both of them using the defaults for PC blend in PrusaSlicer with the exception of adding a draft shield, as I do when printing ABS parts.

I always like to preheat the machine and let it stabilize at or close to the operating temperature, particularly when printing with higher temperature filaments. My firmware does not have a preheat setting for PC Blend (yet) so for the first print I manually dialed in 275 for the nozzle and 110 for the print bed and let it sit. For the second print I preheated to ASA temperatures and let it stabilize and then let the machine continue heating at the start of the print.

Both of the prints came out fine, as expected.

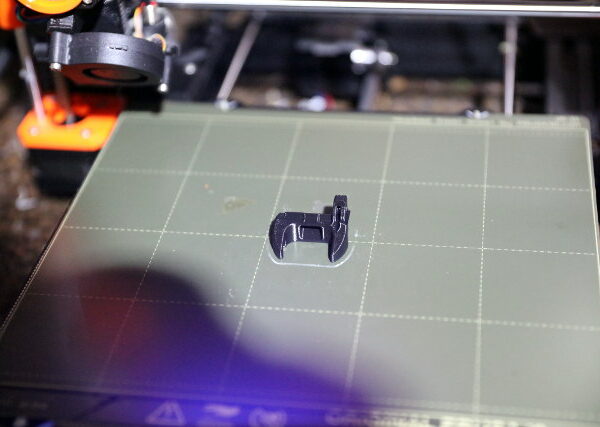

The draft shield popped right off with some gentle squeezing, no other force of any type.

The prints came off after some moderate flexing at 0, 45, and 90 degrees, and took more flexing than a typical ABS print of the same approximate footprint.

The prime line, which had no glue beneath it, peeled right off with no more apparent effort than a similar prime line with ABS.

Overall, I had good luck, and I have plenty left for any parts which need to be strong and/or resistant to heat. They say that the PC blend filament is more resistant to moisture than most others, so it should last a long time.

I think this is a very good product, and my experience shows that it's not much more tricky to print with than ABS or PETg.

RE: First-person report on first use of Prusament PC Blend

Thanks for the review. I alway look forward to your train additions.

Since you're in the U.S. you might also want to try https://www.amazon.com/gp/product/B074DS3986/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

I've found it great for printing parts that require more heat resistance and strength. It's become one of my favorite filaments. Besides all that, it looks GREAT with that CF sheen. 😀

RE: First-person report on first use of Prusament PC Blend

I bookmarked that Amazon link, thanks. However, I sure don't know what I am going to do with an almost-full spool of the Prusa PC Blend, so it will be a while before I need to get anything similar.

I'm happy to report that the remixed fan shroud install was almost trivial. I wrote it up in the MMU2S section since most of what I did to the printer had to do with the MMU2S. Photos and description on line here: https://forum.prusa3d.com/forum/original-prusa-i3-mmu2s-mmu2-general-discussion-announcements-and-releases/report-on-a-couple-of-mmu2s-tweaks/

RE: First-person report on first use of Prusament PC Blend

As an update, I've used the included glue stick as a release agent for all of the few PC Blend prints that I've done so far. I've started using the Layerneer Bed Weld as a release agent for ABS for some time now.

This afternoon I drafted a part that will sit close to a heat-producing component, and I figured that PC Blend would be the filament to use.

The part fits well on the 'good' part of the partially-damaged smooth sheet (above) so I figured it would be a good time to try the Layerneer as a PC Blend release agent.

I'm happy to report that it works just fine. No issues with the higher temperature, and once cooled down to near room temperature, the part popped off with only some gentle flexing.