Fabricating Mechanical Testing Specimens in ZX and ZX45 Orientations

Hello,

I have had my Mk2 since 2017, now I'm in college as a research assistant working with much larger Stratasys Machines. I haven't needed to post on this forum until now...

In Stratasys's preprocessing software called Insight, there is a feature to add stabilizer walls which support verticle walls for very tall and thin parts such as mechanical testing specimens. These walls imbed themselves every 10 or so layers into the part to support it, while also allowing the wall to be easily removed later. This article explains them further: https://www.cati.com/blog/2020/01/3d-printing-take-a-stab-at-stabilize-walls/

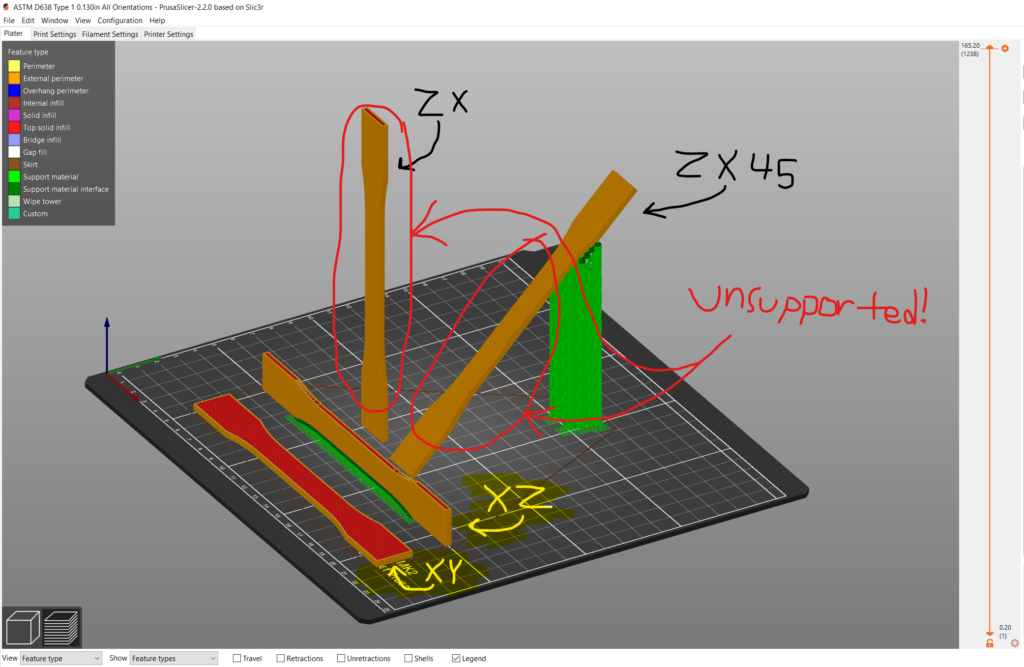

Does anyone know of a slicer that has a feature like this that exports in Gcode? I will soon be fabricating specimens in these orientations on an open-source platform and the ZX and ZX45 specimens need stabilizer walls or an equivalent to prevent build failure:

Quick screen capture to show each of the four orientations, and how ZX and ZX45 orientations are unsupported and prone to failure during fabrication.

Quick screen capture to show each of the four orientations, and how ZX and ZX45 orientations are unsupported and prone to failure during fabrication.

I am also open to other suggestions other than stabilizer walls, I only am asking for a stabilizer wall equivalent because that is what I am familiar with. Any help is appreciated! Thank you for your time!

RE: Fabricating Mechanical Testing Specimens in ZX and ZX45 Orientations

Hi Prtrman,

I am unaware of a slicer that offers what you are asking for, as a tick box solution...

the Two Objects with ZX and ZX45 orientation are not particularly good for printing on an FDM printer as the layer bonds will be weak

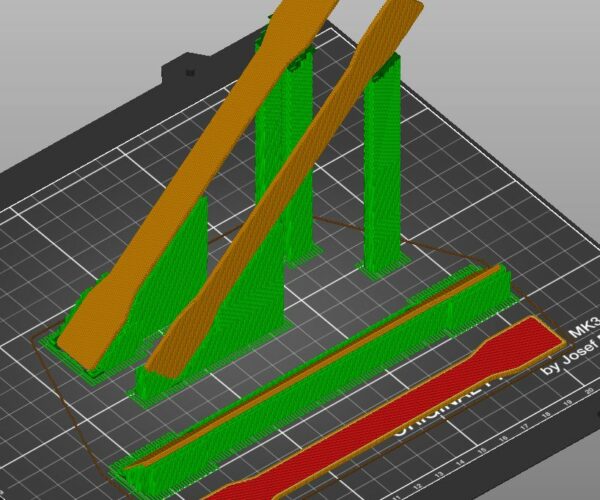

in the picture above the front Red Spatula will be strongest, followed by the horizontal /45degree inclined spatula

then the 45 degree edge on spatula, and the 45degree flat spatula at the back will be least strong.

if you look at the attached zip file, you should see a .3mf file, showing how I used Support enforcers to stabilize the lower part of the back three items

when they print at 45 degrees they should be self supporting, but due to the small contact areas, they need additional support, on the back two items, the lower support is due tothe support enforcers and the upper support is normal support material to stop the item drooping and waving around...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK