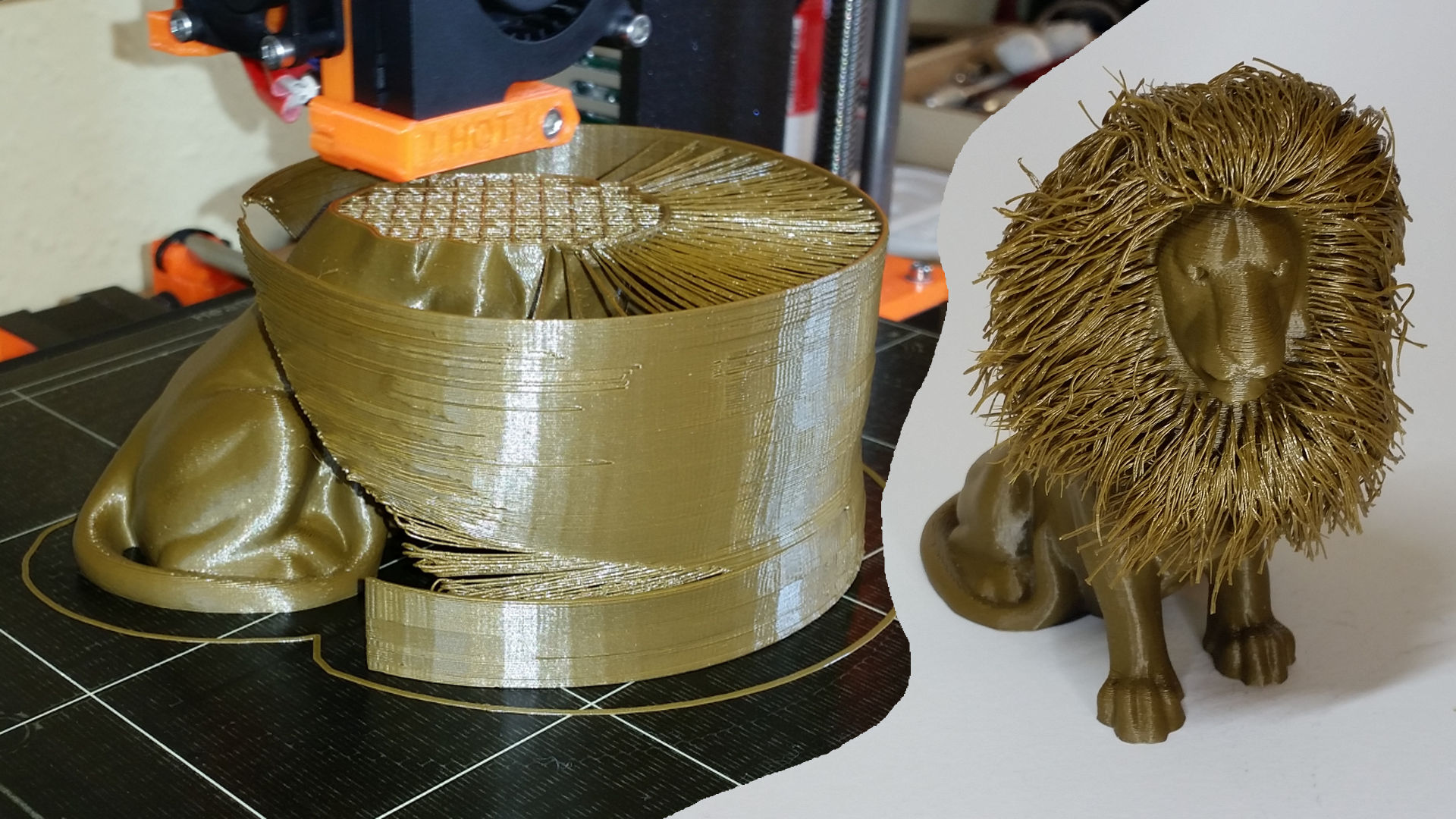

Hairy Lion - that was close to a fail.

Initially, we wanted to kill this print, but it worked well in the end. Later we learned, that it happens quite often, that the shell gets detached from the printing bed in the process.

We also made 2 min video:

Testing software and technologies for 3D design and 3D printing-related guides and reviews.

https://3dwithus.com

Re: Hairy Lion - that was close to a fail.

The shell is waaay too thin at the bottom. I had to thicken it in Blender (boy, that mesh is ugly). I didn't want to mess with the mesh too much but ideally I would just add a little foot at the bottom (perhaps 0.4mm tall, or 0.6, but I suspect that even 0.2 would work - and 5mm wide).

- Gab

Re: Hairy Lion - that was close to a fail.

Don't forget your fan during the hairy lion print.

I only leave the fan off during the first three layers, then turn it on for the remainder of the print

Re: Hairy Lion - that was close to a fail.

The shell is waaay too thin at the bottom. I had to thicken it in Blender (boy, that mesh is ugly). I didn't want to mess with the mesh too much but ideally I would just add a little foot at the bottom (perhaps 0.4mm tall, or 0.6, but I suspect that even 0.2 would work - and 5mm wide).

That could be very helpful. In our opinion, if you load this item with an improved shell as the remix, it could help other makers a lot. Someone on Facebook recommended to use a raft to avoid this issue. But a raft could damage the item's base, which otherwise is ideally smooth.

Testing software and technologies for 3D design and 3D printing-related guides and reviews.

https://3dwithus.com

Re: Hairy Lion - that was close to a fail.

Don't forget your fan during the hairy lion print.

I only leave the fan off during the first three layers, then turn it on for the remainder of the print

The fan worked fine during this print. The problem was a poor adhesion to the printing bed that failed to hold due to a very thin shell. The bed temperature was 100 C plus an extra strong Pritt glue stick.

Testing software and technologies for 3D design and 3D printing-related guides and reviews.

https://3dwithus.com

Re: Hairy Lion - that was close to a fail.

Don't forget your fan during the hairy lion print.

I only leave the fan off during the first three layers, then turn it on for the remainder of the print

The fan worked fine during this print. The problem was a poor adhesion to the printing bed that failed to hold due to a very thin shell. The bed temperature was 100 C plus an extra strong Pritt glue stick.

OK, my bad

Just looked like your fan was off in the photo you uploaded

I did not have any problems with any of the three lions I've printed.

http://shop.prusa3d.com/forum/download/file.php?mode=view&id=5162

These prints were done with Hatchbox wood. Bed temp 55 C and nozzle 213 C fan at 135

Re: Hairy Lion - that was close to a fail.

i just love this Lion!!!

that's a cool print 😎

Re: Hairy Lion - that was close to a fail.

You do know they have created one that has a brim around the support piece. It was uploaded to Thingiverse 2 weeks ago.

Re: Hairy Lion - that was close to a fail.

To chris.b9

Very nice hairy lions! 🙄

You do know they have created one that has a brim around the support piece. It was uploaded to Thingiverse 2 weeks ago.

Thanks, definitely will take a look.

Testing software and technologies for 3D design and 3D printing-related guides and reviews.

https://3dwithus.com

Re: Hairy Lion - that was close to a fail.

I hadn't noticed the version with brim in there - very definitely recommended if you don't want to waste time and filament.

My version is not worth uploading as it was a quick hack and will definitely waste too much time/filament compared to a proper solution.

- Gab

Re: Hairy Lion - that was close to a fail.

Forgive me for stating the obvious, but why don't you print this model with a 3mm or even 5mm brim? It is easy to configure in slic3r.

Re: Hairy Lion - that was close to a fail.

Forgive me for stating the obvious, but why don't you print this model with a 3mm or even 5mm brim? It is easy to configure in slic3r.

Never used so far. Have to try it out. Does it damage model base as raft does?

Testing software and technologies for 3D design and 3D printing-related guides and reviews.

https://3dwithus.com

Re: Hairy Lion - that was close to a fail.

Hi 3Dwithus,

a Brim leaves a thin burr around the periphery of the base, where the brim cracks off after the print is removed from the heat bed.

this can e sanded off or removed easily using a deburring tool. like this

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Hairy Lion - that was close to a fail.

Hi 3Dwithus,

a Brim leaves a thin burr around the periphery of the base, where the brim cracks off after the print is removed from the heat bed.

this can e sanded off or removed easily using a deburring tool. like this

de-burring tool.jpg

http://www.ebay.co.uk/itm/10pcs-BS1010-Blade-with-1pc-NB1100-Burr-Handle-Hand-Deburring-Tool-63RC-Blade-/332073057904?hash=item4d5118be70:g:QeEAAOSwgQ9Vuhsl

regards Joan

Thanks, Joan.

Seems like another tool will be added to our enormous tool collection.

Testing software and technologies for 3D design and 3D printing-related guides and reviews.

https://3dwithus.com

Re: Hairy Lion - that was close to a fail.

Forgive me for stating the obvious, but why don't you print this model with a 3mm or even 5mm brim? It is easy to configure in slic3r.

Never used so far. Have to try it out. Does it damage model base as raft does?

No, the brim is printed outside the model. It comes out easily by hand. You can use an x-acto knife to cut small pieces that don't detach.

If you're using slic3r, define a brim of 3m and look at the preview. Brim is a crucial feature when printing parts with small bases.

Re: Hairy Lion - that was close to a fail.

did you buy your printer ready made?

you seem to be missing - a set of allen keys, some spanners a screwdriver and an acupuncture needle!

🙂

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Hairy Lion - that was close to a fail.

To vitor.j

Thank you!

did you buy your printer ready made?

you seem to be missing - a set of allen keys, some spanners a screwdriver and an acupuncture needle!

🙂

regards Joan

Oh lol, we forgot to add so obvious tools into our 3D printing tools collection. We have 21 then 3 more to add 😆

Testing software and technologies for 3D design and 3D printing-related guides and reviews.

https://3dwithus.com