Super frustrated as nothing seems to work

I am almost at the end and wanting to send back 🙁

I haven’t had a successful anything. I couldn’t get a first layer calibration to work at all. The extruder seems buggy at best, sometimes pulling and sometimes not pulling at all. The first time I tried to load filament it wouldn’t pull it all the way through. After a lot of messing around I eventually got the filament to the hot end (not sure what it’s a called - the tip). I tried multiple times to get a first layer down but it would slip around or bunch up. I watched a video and it showed the heated tip should only be showing some thread but mine was way down and showing lots of smooth silver and the threads. So I adjusted it up. The extruder keeps being a PITA but if I help push it in through the sensor it seems to make it to the tip. But no matter how many times i try to get it to first layer print it either lifts off or bunches up - or doesn’t even put down plastic. And yes the sheet is clean. I’ve got the smooth sheet and have washed it and alcoholed it every time. I can’t believe I’m having so many issues. I bailed after a half successful first layer calibration and just tried to print, silly I know, and I got the same issues.

Using Prusamement filament.

RE: Super frustrated as nothing seems to work

Good morning.

I do not have a mini. so this is guesswork

between the extruder drive motor and the hot end assembly there is a length of PTFE tubing with brass fittings at each end.

is it possible to unload the filament, undo the Brass fittings and remove the PTFE tube, then, after cutting the end of the filament at an angle to make sure the end is ready to feed into the tubing, try feeding the filament into the PTFE tube, by hand.

the filament should go into the tube with negligible resistance,

If the filament enters the tube freely, then meets resistance within a short distance, the brass olive inside the brass nut, may have been tightened too much during assembly, similarly if the filament meets resistance just before it exits the far end of the PTFE tube, then once again the brass nut at that end may have been overtightened.

If you do get this tightness at the ends of the PTFE, the next thing I would do , is cut the section of filament that has teeth marks off the extruder hobbed wheel (Filament Drive wheel) and try feeding the un marked filament down the tube, again, there is a small possibility yhat the extruder idler mechanism is tightened too much, causing distortion to the filament as it passes through... if the unmarked filament passes through the PTFE tube freely, then considder reducing the extruder idler tension, reassemble your printer and try again.

I have noted some users mention that friction in the area of the olives, inside the PTFE Tube, is an issue and they have taken a 2mm drill and drilled out the tight part inside the PTFE tube...

If you choose to try this option, please remember that PTFE particles have a very high melting point, and IF you don't fully clear any particles from the tube, YOU WILL clog your nozzle with PTFE Particles that will not be easy to remove.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Super frustrated as nothing seems to work

Are you sure that your Z offset is correct?

--------------------

Chuck H

3D Printer Review Blog

RE: Super frustrated as nothing seems to work

Like Joan, I also do not have a Mini -- but very often problems like this are easily resolved AFTER the user has read the printing handbook that comes with every Prusa printer.

Not what you wanted to hear, but reading the guides Prusa offers was an immense help to me when I started this hobby years ago.

ps: your print sheet is not clean, it has a coating of something on it, and that isn't helping, at all.

RE: Super frustrated as nothing seems to work

@tim-2

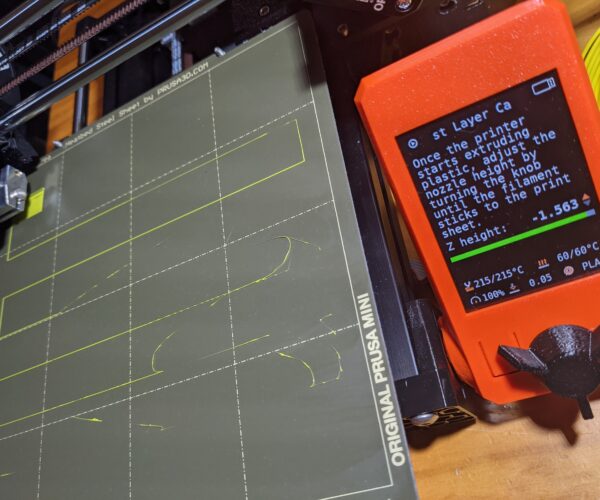

Hi Tim, thanks for the reply. I bought the smooth sheet which has the coating on it apparently that helps make things smooth. I’m wondering if that’s a mistake as the filament isn’t sticking down at all. I’ve had some success now with readjusting the hot end and the filament tubing. I can get it to come through and melt but for the life of can’t get it to stick down (see pic). I’ve cleaned the heck out of it with dish liquid, hot water and alcohol wipes but no good. Is there some sort of cover on the smooth steel sheet? Have I been stupid enough to not remove it? I’ve read it’s supposed to have a plastic sort of film on it.

The pic shows the base layer of the prusa logo print which half made a first layer and then the head just pushed it off to the side.

RE: Super frustrated as nothing seems to work

Like Joan, I also do not have a Mini -- but very often problems like this are easily resolved AFTER the user has read the printing handbook that comes with every Prusa printer.

Not what you wanted to hear, but reading the guides Prusa offers was an immense help to me when I started this hobby years ago.

ps: your print sheet is not clean, it has a coating of something on it, and that isn't helping, at all.

The marks on the sheet is alcohol residue. I have since tried washing it as suggested by the guides and redoing the alcohol wiping. NO luck though.

RE: Super frustrated as nothing seems to work

That does not appear to be low enough - the first layer should be fused.

--------------------

Chuck H

3D Printer Review Blog

RE: Super frustrated as nothing seems to work

If it's not pulling filament adjust the idler screw.

Your first layer is not squished enough. Re-run the first layer calibration until you get a sheet that holds together.

Cheerio,

RE: Super frustrated as nothing seems to work

I’ve tried everything. I’ve watched all the YouTube videos, read all the forums - I can’t get the first layer to stick. The steel plate I have is the smooth one and I’m starting to think that was my mistake and I should have gone for the standard steel. The steel smooth one I have is slick and slidy and nothing sticks to it so how can the filament.

I started with PLA and my most recent try has been with ABS - both Prusa brand. Same problem with the ABS even though the hot end got to 255 degrees and the plate 100! I made a couple of successful lines in the first layer calibration and then the end lines lifted off.

RE: Super frustrated as nothing seems to work

Oh and the base plate is clean. I’m getting OCD I’ve cleaned it so much, dish soap, soft cloths, sponges, alcohol lens cleaner - I’ve tried everything.

RE: Super frustrated as nothing seems to work

@auilabs

[Humor intended]When you start dreaming of cleaning your print plates, you have done it too much.[/Humor intended]

Can you do another first layer test and post images?

--------------------

Chuck H

3D Printer Review Blog

RE: Super frustrated as nothing seems to work

The first layer may fail due to:

- a plate that is not clean

- the nozzle is too high over the bed

- the nozzle is too closed to the bed

- the extruder is not working properly (incorrect amount of plastic coming out of the nozzle)

- a partial blockage of the hotend (which Joan already suggested above).

- improper hotend/bed temperature

- wrong filament (are you sure that filament material is the one you think it is?)

I am sure I am leaving some other causes (that hopefully are minor). ABS and PLA work quite differently, so I would focus on getting the problem diagnosed with a single filament first (PLA would be my advice).

If the bed is clean, the temperatures are right and so is the filament, things should work ok IF the extruder/hotend are actually delivering the expected amount of plastic.

Try to remove any preconceptions you might have about what is wrong and share what seems to happen and the conditions around as accurate as possible so other users can be most helpful.

RE: Super frustrated as nothing seems to work

I’m going to try adjusting the Pineda height as I did it with a credit card but after some more reading/suggestions I’ll measure it with calipers and make sure it’s 1.5mm offset. Then I think I’ll try adjusting the temp for PLA higher. It’s such a PITA doing these tests as I have to clean the heck out of the sheet between every test 🙁 so it takes ages.

RE: Super frustrated as nothing seems to work

There is always a fine-tuning with the Live Z calibration. But right now, watching your last picture, it seems as if you have a good nozzle height when printing but still the Prusa-logo test did not adhere. That makes me think that maybe not enough plastic is being extruded.

For testing that you may measure if the input length of filament is matching what is commanded. You can do that by preheating your printer for let's PLA next commanding a manual move of 100 mm, Before doing that, mark on the filament 100mm from the current input tube edge outward.

While the filament is extruded, check whether the mark goes till the edge of the input tube or it stops short. If it is short, then that might signal some possible partial blockage in your hotend. If it goes exactly the 100 mm (or a similar amount) commanded, then we can put that potential cause to rest.