random missing layers

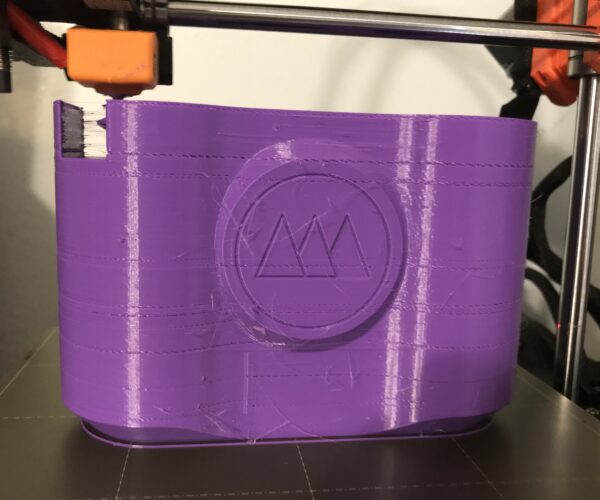

new mini+ has some missing layers. there is some extrusion on the missing layers, but not a lot. Is my idler tension wrong? Polymaker PLA filament. printing at 210c default settings. Thank you!

new mini+ has some missing layers. there is some extrusion on the missing layers, but not a lot. Is my idler tension wrong? Polymaker PLA filament. printing at 210c default settings. Thank you!

Best Answer by Dronah:

(2) Prusa mini hotend / underextrusion fix - YouTube

I followed this video and it fixed all my problems! The Hulk with supports is before, and without is after. Thank you for all your help.

RE: random missing layers

It's possible. Wrong belt tension?

Bad filament dimension?

The photo have very small size...

RE: random missing layers

Sorry for small picture here is a better one. Thank you for your suggestions, but I don't think either of those is the issue. I measured the filament and it was exactly 1.75mm and all of the layers that are extruded correctly are perfectly aligned.

RE: random missing layers

Ok. Now I see.

It's bad extrusion. Now You have a under-exctrusion in some layers. First clean hotend head. It's have a two vays.

1. manualy in screen change the hotend temperature to 240-250 deg, and prune filament in other screen where setup extreder value. Set value over 40-50. Wait. And set temp to lovely 230-235. Repeat extrusion. Set normal temp for PLA and repeat extrusion.

2. Set more power in extruder screw. May be filament is very soft. I have'nt this filament in my markets.

3. May be need change PTFE tube.

Often I use first way.

Sumtomes for very hard or soft filaments I change the extruder screw forse.

After 50-70 printed hours I burning print head in open fire, ofcouse it's dangeres and I use the 3M mask with coal filters. Before use open filre on hed, had was uninstall from hotend.

some videos:

- But i don't use cold cleaning, it's may bee damadged the axis calibrating and some printer parts.

- burning nozzle. But burn all plactic is tocsic! I use respirator.

change PTFE tube

Oh, in first time you can added 5-10 degree for PLA, it chahge flow, may be you used very fast printing speed and honentd don't melting PLA in small time. More speed -> more flow mm3 need -> more owerheat in extruder need(experemenal for different PLA and different speed)

RE: random missing layers

@javacer

Thank you so much! I will try this and give you an update when I’m done.

RE: random missing layers

(2) Prusa mini hotend / underextrusion fix - YouTube

I followed this video and it fixed all my problems! The Hulk with supports is before, and without is after. Thank you for all your help.