RE: problem with broken filament

I can't really tell from the picture, but if you're saying the filament's broken inside the bowden tube, you can unscrew the brass coupler and then push it out with another piece of filament.

RE: problem with broken filament

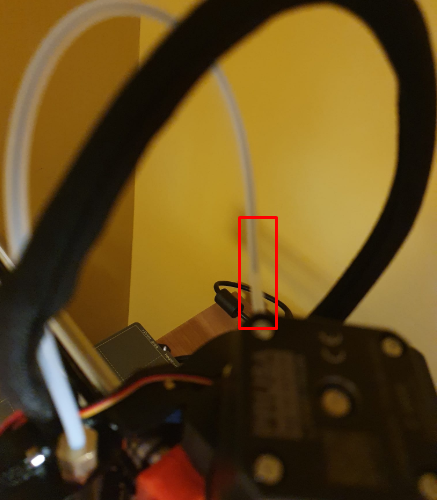

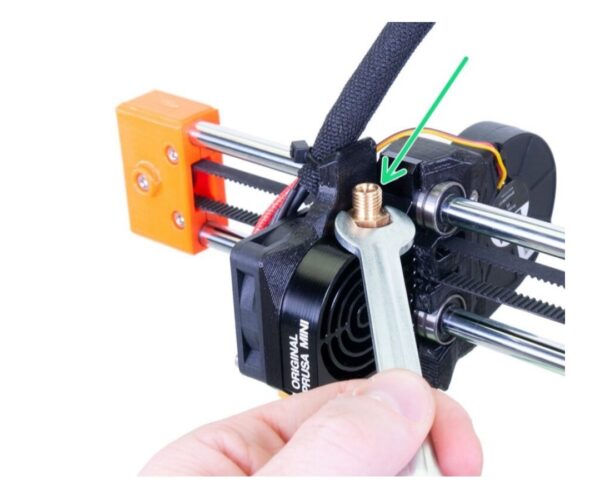

Seeing the picture I understand your filamemt is cut after the extruder gear. This means you can't push it or retract it. You need to use the supplied wrench tool to remove the brass fitting.

Then you will end up with the filament exposed. Go to your printer menu Filament->Preheat->PLA(or other type depending what filamemt you have loaded) then wait for the printer to reach 215C and gently pull the filament off.

Then refit the brass fitting and tighten it in place. Load your new filament and let it purge.

Hopefully everything works and you got no clogs left. Try it and let us know!

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: problem with broken filament

I resolved with your suggestion, thanks !

But now my problem is that from hot-end does'nt purge anything ...

For this new problem I try to find some similar post in forum.

RE: problem with broken filament

@giluka

Your nozzle might be clogged its better to try and see if you have any filament stuck inside your hotend.Try the guide below.

https://help.prusa3d.com/en/article/cold-pull-mini_126399

If that doesn't help you can find more info in this article.

https://help.prusa3d.com/en/article/clicking-extruder-under-extrusion-and-clogging-mini_112011

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: problem with broken filament

Thanks for your help.

I resolved simply putting a needle into nozzle (275 degree): in this way the formed 'cap' of filament go out.

RE: problem with broken filament

Great! Glad it worked. I don't know if you used the supplied needle but there is a needle especially for this purpose which comes with your printer inside the cleaning accessories.

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: problem with broken filament

I stopped having broken filament when I move the extruder to the far left for loading and unloading:

https://github.com/prusa3d/Prusa-Firmware-Buddy/issues/311

Also, adjust the extruder idler wheel tension so it doesn't grind the filament.

Mark