printing problems after 10cm heigth

Hi All,

I have a problem with printing tall pieces, after 10cm the surface gets very irregular. also, the top view is not how it is supposed to look.

The shape is for tensile testing, so no I cannot print it in another orientation.

It is ABS, 0.1mm layer height

RE: printing problems after 10cm heigth

I haven't printed with ABS, but have done a lot of ASA, pretty similar.

Can you take a picture of the whole part? None of the surface looks like I would expect. I get near perfect surface finish with ASA except for a few zits. Features are very sharp and exactly as designed. Things get wonky if it starts to warp.

Are you printing in an enclosure? That will help a lot.

Are you drying the filament before printing? That is critical for good quality.

Can you try with a draft shield (full height skirt, find it in the Skirt and Brim part of the Print Settings)

Regards,

Mark

RE: printing problems after 10cm heigth

Hi Mark, thanks for your reply!

Here is a picture with my setup, the bottom part of the product is very smooth, so I don't think it has to do with the filament.

I don't have an enclosure, the draft shield is a good idea!

RE: printing problems after 10cm heigth

@jerzeek

you could try something like this

the links are at 45 degrees so they will print without support

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: printing problems after 10cm heigth

@jerzeek

You got 2 good points here...

One with it being thin and tall with limited support for it, there is going to be some movement in the print as it prints, and the higher up it goes that movement will be more noticeable. Joan's suggestion about having a second one with support links between the 2 is a good idea to help keep them straight.

Also another thing that was mentioned was an enclosure, ABS needs to cool slowly. it might be a case where it is warm enough in your area for the ABS to cool slowly due to the heat coming off the heat bed, but as the height increases, that heat might be dissipating. Passive heating from the heat bed might be enough if the Mini was placed in a box large enough for it and to also cover the bed movement. You could try that and check the results as well.

May the odds be forever in your favor 🙂

Shane

Shane (AKA FromPrusa)

RE: printing problems after 10cm heigth

@fromprusa

Regarding height and bed movement - wouldn't orienting the part 90 degrees, for wider side to be parallel with Y movement, help? It may limit wobble up there a bit.

RE: printing problems after 10cm heigth

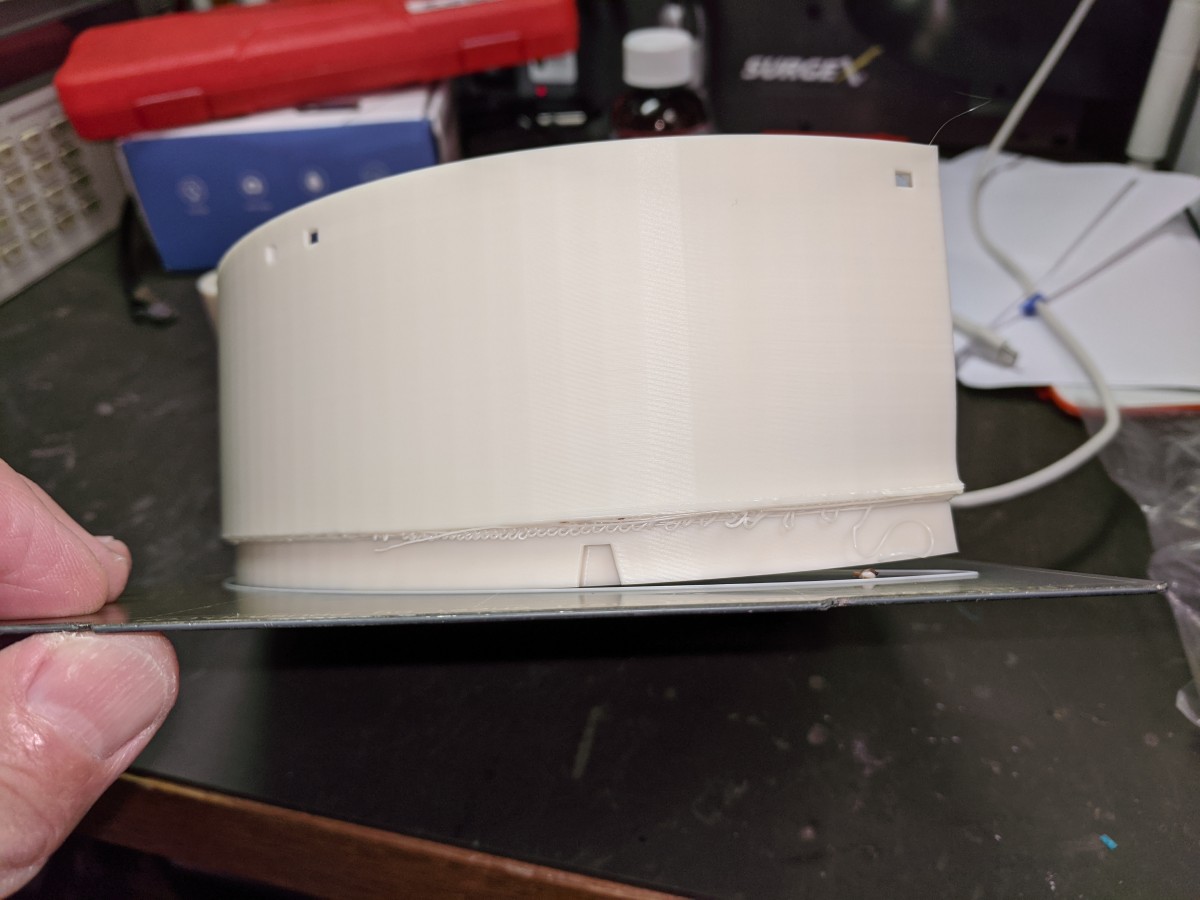

I tried making some tall thin segments for my filament dryer with ASA. They pulled up off the bed and generally warped. Overhangs were terrible too.

Then, with a draft shield, results were way better. There are still some issues, but they are usable. Notice that the draft shield warped pretty badly, but that does not hurt anything.

Regards,

Mark