I cant get the first layer calibration to work

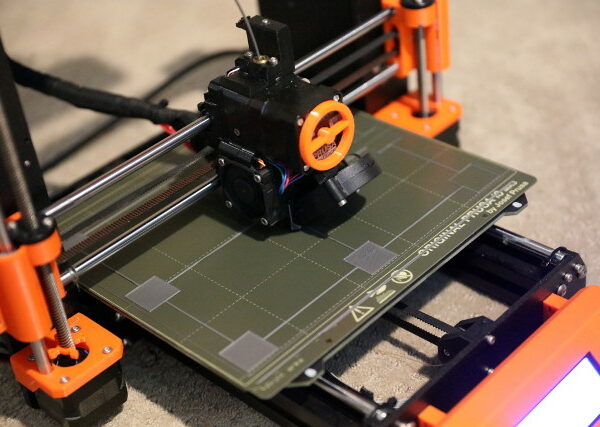

Attached is paint drawing on what happens when I run my first layer calibration. I've had the printer for weeks and cannot find out what's wrong. I have my Z offset to 1.080 but this keeps on happening. I do have 91% ISP on the way so I cant clean my steel textured sheet yet but Im looking for any other pointers everyone has here. Thank you for your time.

RE: I cant get the first layer calibration to work

Rounded corners and a blob sure look like the Z is too high. There may be an adhesion issue as well.

I would first make sure that the build plate is really most sincerely clean and then try lowering your Z value, maybe 50 or so at a time, and it should start to adhere much better.

RE: I cant get the first layer calibration to work

Try printing the Prusa logo. Start with your Live-Z high (less negative) and continue lowering it in 0.02mm increments until things start to stick. As you get close, the lines should start to stick better to the point that you can't nudge them away with a fingertip. Continue lowering until any gaps between extrusions start to close up.

I wrote these notes for the Mk3, but the basic approach is the same for the Mini. If you don't have a Mini-specific test print, the Prusa logo gcode is fine. Just stop it after the 1st layer.

RE: I cant get the first layer calibration to work

I forgot to mention it but I'm really sold on those 'patch' type Z test prints, the 'My Way' or similar.

The one I use is a 3x3 square type, which gives you a good idea of how your Z calibration is overall, and if any tweaks need to be made at any of the sides or edges.

RE: I cant get the first layer calibration to work

If you don't have IPA, you can use denatured if you have it available, or wash sheet with dish soap (just don't use sponge you already use for dishes) and rinse thoroughly. Don't touch the surface at all. This helps with tectured sheet adhesion too.

Angled corners and bunched filament usually mean your Z is too high. Go lower. There is no universal number how low it should be, everyone'spprinter is different, if you adjust height of MINDA probe to a plastic card height it's usually somewhere between -700 and -1300.