Heatbed not centered

Hello everyone,

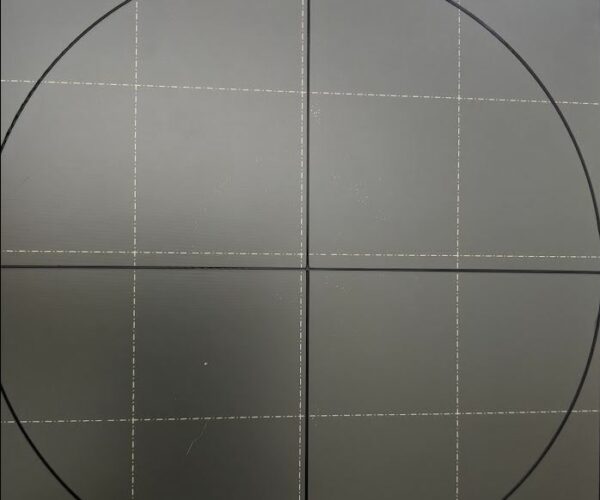

I received the printer last week, assembled and started printing without many issues, but one of the things that surprised me is that the heatbed does not seem to be centered (the center in prusaslicer does not correspond with the center in the printer) as seen below.

I don't have any need for now, but if I ever decide to print something relatively large, I could see it becoming an issue.

Has anyone encountered this ? Any suggestions?

RE: Heatbed not centered

the easiest thing to do, is re scale the model in Prusa slicer so that it is Full size, 250mm x 210 mm, and try re printing it. if the oval shows two straight sections then it would suggest that the print area is restricted. somehow.

If the print succeeds and remains out of line with the markings on the build sheet, then please accept that there are manufacturing tollerances involved and that the markings are only a guide...

My latest build plate has no markings on it. at all, and I have a selection of build plates with different graphics on them, for instance the textured sheet simply has the perimeter and text plus 4 tiny crosses on the print area

if there is a restriction of print area, then please be aware that , the X and Y axis do not have endstop switches, they work by sensing the rise in motor current when the X or Y axis collide with the end of travel.

It is possible that the printer is erroneously sensing the increase in current earlier than expected...

lots of things could contrive to cause an issue like this, including, belt tension, Y axis ubolt tightness, x axis backplate tightness and friction within the bearings, Cable bundle flexing resistance, cables catching o n something, ... and the build plate could, in fact be off centre

I would start by lubricating the smooth rods, if the linear bearings were not lubricated during the build process (Yes I do know what the assembly manual says! ) you are seeing an issue that displeases you, so consider this as your first maintenance period.

https://help.prusa3d.com/en/article/i3-printers-regular-maintenance_2072#rods-and-bearings

the link above discusses application of lubrication after the build (I lubed mine during the build... and have not had problems like this )

the next easiest things to change are the Ubolt tension and the X axis back panel tension, try loosening both a tiny bit...

best wishes, and good luck,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Heatbed not centered

I don't have any need for now, but if I ever decide to print something relatively large, I could see it becoming an issue.

Has anyone encountered this ? Any suggestions?

The markings on the steel sheet are not accurate and should not be relied upon. It's a trivial test to do, try printing something with nominal max dimensions of 180x 180 like the attached STL. The printer axes can move a bit more than 180mm, so you should have no problem printing the max size.

Probably the bigger issue is achieving uniform adhesion across the bed, it might require careful adjustment of the Z offset.

RE: Heatbed not centered

So I finally had time to post the solution I came up with for this.

In general the off center of the heatbed was not affecting the maximum size of the things I could print, I successfully printed all the area (180x180), although it was using some of the margins of the building plate. I lubricated all the bearings just in case, but it made no difference, I think mine were properly lubricated from factory (still not a bad thing to do).

Eventually I solved it just by entering in the Prusaslicer and changing the origin values in the Bed Shape settings (Printer settings tab). After a couple of quick prints for calibration it is now centered and working like a charm. It also opens the possibility to fully utilize the margins of the build plate in the future 🙂

Note: If you change the default values from the bed shape you lose the Specific Prusa mini 3d model in the plater of Prusaslicer. However you can reload them in the Texture and Model sections in the same window where you change the Bed Shape. They are located in the installation folder.

RE: Heatbed not centered

My bed is the same but it also suffers from a xz error which means that except from the off center the x line is not parrallel to the grid line.

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: Heatbed not centered

@aurru

I changed the origin values and had no difference in alignment, still off centered. Not sure what I'm doing wrong.

RE: Heatbed not centered

@aurru

Hello everyone -

Same issue on my mini as several here. I can also utilize the full area, just not rely on the markings on the sheet. The more troubling, to me anyway, is the inaccurate representation in the slicer. For some things, I pack them pretty tight and have used the lines for guidance. As mentioned though, it's not a hard work around. I also have found that setting the origin values did not affect anything, at least in 2.3.0.

Thanks.

RE: Heatbed not centered

Follow-up to earlier post in case someone else searches on this topic.

Setting the origin did indeed work. For my mini (Jan2021) under printer settings/General/Bed Shape - Origin X value: +2.9, Origin Y value: +1.9.

In response to @aurru, to have an effect on the print, you must remember to re-center the object after you set these values accordingly. That did the trick for me.

RE: Heatbed not centered

Note: If you change the default values from the bed shape you lose the Specific Prusa mini 3d model in the plater of Prusaslicer. However you can reload them in the Texture and Model sections in the same window where you change the Bed Shape. They are located in the installation folder.

C:\Program Files\Prusa3D\PrusaSlicer\resources\profiles\PrusaResearch on mine. Load the SVG and STL. Looks correct and prints great. I used X 2.8 and Y 2 on my Mini. May be a good place to start.

RE: Heatbed not centered

This question seems to come up a lot, and it doesn't mean there is anything wrong with the printer. I don't think those lines were to ever exactly match up with the build plate in real life, but to be merely used as a rough guide. I suspect it is why the lines have been removed from the newer sheets like the satin sheet. To stop the questions, and likely many support inquiries from people who think they have faulty printers because they don't line up. Perhaps they'll disappear from the smooth PEI sheet as well after they burn though current stock of the sheets and order a new batch?

If they had wanted to make it possible to easily line them up, there would have been some setting in the firmware to home the hot end. You'd enter the setting and then use controls to jog the hot end to one of the corners or to the center of the bed then save the new reference set point.

RE: Heatbed not centered

Mine had 15+mm on one side and almost hit the other side on a large print, so I did need to center mine a little better. Not sure it would have made contact at 180mm, but it would have been less than a mm.

RE: Heatbed not centered

The same deviation also applies to my Prusa MINI. It is annoying that due to the Y axis deviation, the nozzle can collide with the screws (for aligning the spring steel plate) of the heating plate (which unfortunately happened twice; initially, because I assumed that the PrusaSlicer and print bed are aligned with each other and once after a PrusaSlicer update). I do not see adjustments in the PrusaSlicer as the primary solution, as this makes the gcode printer specific (e.g. bad in the case of a print farm) or after a PrusaSlicer update, the changed settings were gone (maybe I did something wrong). Therefore, after the complete assembly, I pushed the Z-axis assembly away from the front plate by approx.2.5mm so that the alignment of the print area of PrusaSlicer matches the spring steel plate (in Y direction) and the nozzle does not collide with the screws of the heating bed, when the entire print area is used. There is also an X axis deviation, but this is not a major problem, except that the heat distribution is not optimal outside the marked print area. In order to mechanically correct the X axis deviation as well, one would have to increase the distance between the extrusion and the Z axis assembly, which is not as easy as the Y axis correction. A correction in software would only make sense on the printer itself, whereby in my opinion the constructive correction is to be preferred (small and temporary corrections in software would be OK). Mechanical problems should not always be fixed by the software :). It would be interesting to get an opinion from a Prusa technician. where this problem could come from :).

RE: Heatbed not centered

I tried this. I moved the origin of my mini by y -3

The slicer show the origin moved and moved the print over to the adjusted origin but says out of print area.

RE: Heatbed not centered

I thought that I backed out above change to the slicer but the print is now moved over y-3. One gets a red background for the gcode screen. Live in the red, I guess.

RE: Heatbed not centered

My bad. So when the printer levels the bed before a print, the physicals bounds are noted. A raft which is out of bounds according to the slicer will get printed where the leveling show print bed available and will not get printed where the leveling shows print bed not available.

My guess.

As a sanity check:

Out of curiosity I stacked two smooth plates together, the lines did not match by about 1.5mm although each was square to the bed within the limits of my measuring tools. Then I turned them over and got a slightly larger difference ...

One plate differed by 2mm from one side to the other but the other plate, although not absolutely aligned from side to side was within the thickness of the lines.

So: As @d0ug surmised, the lines are a guide, not a measurement reference. This makes sense when you think about it; everytime you remove and replace the sheet it will be marginally different despite the guide pins.

Cheerio,