Consistent layer bulge on whistle test print

The mini is my first printer. Just got it last week and spent the first few days finding out that I needed to swap out the PTFE tube in the hotend to keep it from clogging. The printer was unusable initially.

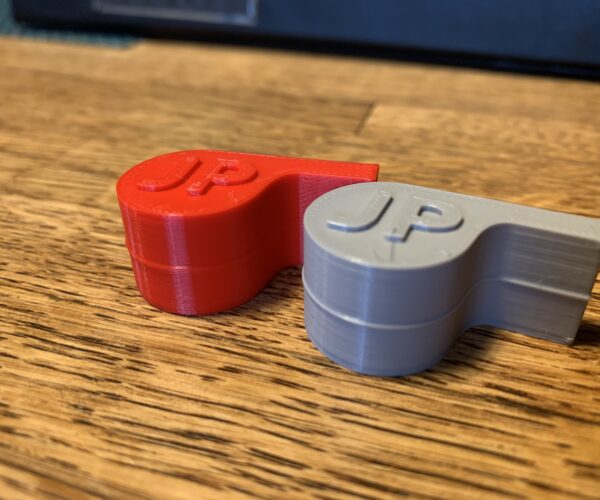

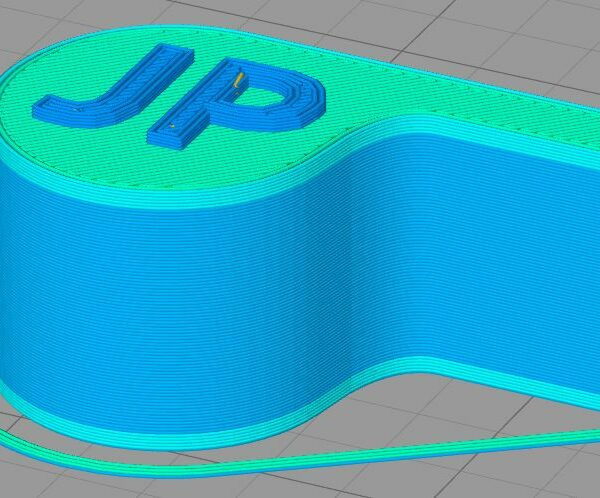

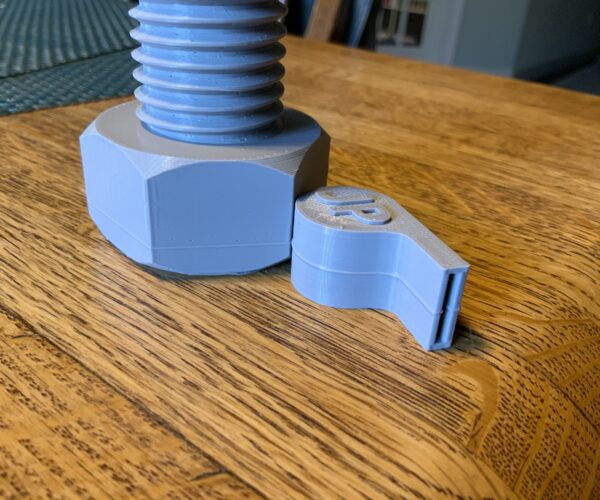

Now that that seems to be resolved (for the moment) I have been having issues with horizontal bulges during prints. I have printed the whistle test print on two separate days and with two different filaments (Prusament (red) and Hatchbox (grey)) and have gotten the bulge in the exact same spot in the middle of the print. As far as I can tell there is no change to wall thickness in the gcode that would cause this as the whistle is just a vertical wall during this part of the print. Any ideas?? Thanks!!

RE: Consistent layer bulge on whistle test print

Where did the g-code come from, was this off the USB stick?

RE: Consistent layer bulge on whistle test print

The mini is my first printer. Just got it last week and spent the first few days finding out that I needed to swap out the PTFE tube in the hotend to keep it from clogging. The printer was unusable initially.

Now that that seems to be resolved (for the moment) I have been having issues with horizontal bulges during prints. I have printed the whistle test print on two separate days and with two different filaments (Prusament (red) and Hatchbox (grey)) and have gotten the bulge in the exact same spot in the middle of the print. As far as I can tell there is no change to wall thickness in the gcode that would cause this as the whistle is just a vertical wall during this part of the print. Any ideas?? Thanks!!

Did you use the original gcode file from the Prusa USB stick?

Possibly there is a hardware error. Too low extruder idler tension, partly dirty hotend or too high frictional resistance in the PTFE tube. Loose seated PTFE tube...

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Consistent layer bulge on whistle test print

@karl-herbert

Thanks for the quick replies! Yeah, I failed to mention that it was the gcode that was preloaded onto the USB stick. Since everything is brand new, I hope it's not too high resistance in the PTFE. I'll take a look at the extruder tension. That's adjusted by the little screw on the bottom of the extruder? I have been using the factory setting.

RE: Consistent layer bulge on whistle test print

@karl-herbert

Ah okay. Perfect. I'll give it a try. But would this explain the bulge occurring at the same place in the print each time? I'm still learning how these things work.

RE: Consistent layer bulge on whistle test print

Have you tried any other prints. Do they have the same banding?

RE: Consistent layer bulge on whistle test print

@rathbunc

Were you able to detect any temperature changes at the nozzle in this area? Is the Z-axis running smoothly throughout - without blockages? The error does, as i can see on the pictures, not seem to occur at exactly the same height.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.